Pulse Laser Cleaning Machine: The Ultimate Solution for Precision Surface Treatment (100W - 500W)

2025 Market Price Guide: Understanding the Cost

“How much does it cost?” is the most common question. While final pricing depends on shipping and customization, here is a transparent guide for 2025:

Entry Level (50W – 100W): Typically $3,500 – $5,000.

Best for: Small artifacts, spot cleaning, hobbyist or small workshop use.

Industrial Standard (200W – 300W): Typically $6,000 – $10,000.

Best for: Mold cleaning, auto parts renovation, daily industrial use. (Most Popular)

High Power / Automation (500W+): $15,000+.

Best for: Automated production lines, high-speed requirements.

Note: Prices vary based on the Laser Source Brand (JPT/Raycus/IPG) and 2D/3D Scanner configuration.

1. What is Pulse Laser Cleaning?

Pulse Laser Cleaning is a non-destructive surface treatment process that uses high-frequency light pulses to remove rust and paint without damaging the substrate. This instantly evaporates or peels off rust, paint, oil, and oxides from the surface.

Because the laser beam is not continuous, the base material does not accumulate heat, making Pulse Lasers the only safe choice for cleaning precision molds, aerospace components, antique restoration, and thin metal sheets.

2. The Critical Choice: Pulse Laser vs. CW Laser

Many buyers confuse Pulse Lasers with Continuous Wave (CW) Lasers. Choosing the wrong one can ruin your parts.

|

Feature

|

Pulse Laser Cleaning Machine

|

CW (Continuous Wave) Laser

|

|---|---|---|

|

Beam Type |

High-peak energy, short pulses |

Continuous beam output |

|

Heat Impact |

Low / None (Cold Cleaning) |

High (Heat Accumulation) |

|

Substrate Safety |

100% Safe (Non-destructive) |

Risk of melting/warping texturing |

|

Precision |

Micron-level control |

Rough cleaning |

|

Best Application |

Molds, Engine Parts, Paint Stripping, Restoration |

Heavy Rust on Bridges, Ships, Steel Structures |

|

Cleaning Finish |

Clean, metallic white finish |

Can leave dark oxidation marks |

|

Cost |

Higher initial investment |

Lower entry cost |

Our Verdict: If you need to clean thick rust on a bridge, buy a CW laser. But if you need to clean an injection mold or a car engine part without altering its dimensions, you must use a Pulse Laser.

3. Lab Data: Real Cleaning Efficiency Test

At the Chihalo Application Lab, we tested our 50W, 100W, 200W, 300W and 500W Pulse Model against common contaminants. Here is the real-world performance data:

50W Laser Paint Removal

100W vs 200W Laser

300W Laser Wood Stripper

500W Laser Rust Removal

4. Proven Applications & Industries

Our machines are currently serving clients in:

Mold Industry: Cleaning tire molds, injection molds, and rubber molds online without cool-down.

Automotive Manufacturing: Pre-welding cleaning of gearboxes and precise paint removal on body parts.

Heritage Restoration: Removing centuries of grime from bronze, stone, and artifacts.

5. Technical Parameters

100W-500W MOPA Pulse Laser Cleaner: Complete Power Range & Specifications

|

Model

|

CHL-100M-A

|

CHL-200M-A

|

CHL-300M-A

|

CHL-500M-A

|

|---|---|---|---|---|

|

Operation Mode |

Pulse & Continuous |

Pulse & Continuous |

Pulse & Continuous |

Pulse & Continuous |

|

Laser Power |

100W |

200W |

300W |

500W |

|

Wavelength |

1064nm |

1064nm |

1064nm |

1064nm |

|

Pulse Energy |

1.5mJ |

1.5mJ/15mJ |

1.5mJ/15mJ |

1.5mJ / 15mJ / 50mJ |

|

Beam Quality |

≤1.6 |

≤1.6 |

≤1.6 |

≤1.6 |

|

Pulse Range |

2~350ns |

30~500ns |

30~500ns |

30~500ns |

|

Frequency Range |

1~4000kHz |

1~4000kHz |

1~4000kHz |

1~4000kHz |

|

Fiber Cable |

3-10m |

3-10m |

3-10m |

3-10m |

|

Cooling |

Air Cooling |

Air Cooling |

Air Cooling |

Air Cooling |

|

Scaning Length |

<200mm / <650mm |

<200mm / <650mm |

<200mm / <650mm |

<200mm / <650mm |

|

Storage Temperature |

-10 ~60℃ |

-10 ~60℃ |

-10 ~60℃ |

-10 ~60℃ |

|

Work Temperature |

0 ~40℃ |

0 ~40℃ |

0 ~40℃ |

0 ~40℃ |

|

Machine Size |

440*185*570mm |

440*185*570mm |

440*185*570mm |

440*185*570mm |

|

Machine Weight |

25KG |

25KG |

25KG |

25KG |

|

Input Power |

110~220V, 50~60Hz |

110~220V, 50~60Hz |

110~220V, 50~60Hz |

110~220V, 50~60Hz |

6. System Configuration Options

Chassis (Backpack, Portable, Enclosed)

Backpack Configuration: Ideal for maintenance work requiring maximum mobility. The ergonomic design distributes weight evenly, allowing operators to work for extended periods without fatigue.

Portable Trolley Setup: Professional-grade mobile solution featuring robust construction with shock-resistant components, perfect for workshop environments.

Enclosed Industrial Unit: Fully automated systems designed for high-volume production environments with integrated safety features and remote monitoring capabilities.

Check All Laser Cleaning Machines

Power Requirements & Electrical Specs

⚪Input Voltage

110V ~ 220V, 50Hz ~ 60Hz

⚪Laser Power

100W, 200W, 300W, 500W

Cleaning Head and Software

Chihalo Turbo Cleaning Head

2025 Chihalo Pulse Laser Cleaning Machine’s Turbo Cleaning Head and Software, choose a faster motor to double cleaning speed, and bigger mirror to get more laser’s hola power, adding second touch screen on head to achive remote control. It comes with more safety customized functions, contact engineer to get more information.

Chihalo Turbo Cleaning Head

A cost-effective cleaning system suitable for end customers without special customization requirements. The system has dual motors, comes with 8 scanning shapes and over 20 national languages. The maximum size can reach 650mm, with a modular design that makes replacement and maintenance easier.

7. Performance Comparison Chart

Cleaning Speed by Laser Power & Material Type

| Material Type | 100W Speed | 200W Speed | 300W Speed | 500W Speed |

|---|---|---|---|---|

| Light Rust | 2-4 m²/h | 4-8 m²/h | 6-12 m²/h | 10-20 m²/h |

| Heavy Rust | 1-2 m²/h | 2-4 m²/h | 3-6 m²/h | 5-10 m²/h |

| Paint/Coating | 3-5 m²/h | 6-10 m²/h | 9-15 m²/h | 15-25 m²/h |

| Oil/Grease | 5-8 m²/h | 10-16 m²/h | 15-24 m²/h | 25-40 m²/h |

Process Time Comparisons

| Application | Traditional Method | Laser Cleaning | Time Savings |

|---|---|---|---|

| Rust Removal | 45 min/m² | 12 min/m² | 73% |

| Paint Stripping | 60 min/m² | 15 min/m² | 75% |

| Grease Cleaning | 30 min/m² | 8 min/m² | 73% |

| Weld Prep | 25 min/m² | 7 min/m² | 72% |

Cost per Square Meter Analysis

Traditional cleaning methods vs. portable pulse laser cleaner:

- Sandblasting: $2.50-4.00 per m²

- Chemical Cleaning: $3.00-5.50 per m²

- Manual Cleaning: $8.00-15.00 per m²

- Pulse Laser Cleaning: $0.08-0.20 per m² (including energy costs)

Surface Quality Measurements

Post-cleaning surface analysis demonstrates consistent quality improvements:

- Surface Roughness: Ra 0.8-3.2 μm (controllable)

- Cleanliness Level: Sa 2.5 to Sa 3 achievable

- Dimensional Accuracy: ±0.01mm maintained

- Surface Activation: Improved coating adhesion

8. Complete Application Solutions

Surfaces that Pulse Laser Cleaning Can Clean

Metal Surface

Pulse laser cleaning machines excel in metal surface preparation and restoration applications. The non-destructive laser surface cleaning process removes contaminants while preserving substrate integrity.

Primary Metal Applications:

- Automotive Industry: Engine component cleaning, body panel preparation

- Aerospace: Turbine blade maintenance, structural component cleaning

- Marine: Hull cleaning, propeller restoration

- Manufacturing: Weld preparation, pre-coating surface treatment

- Construction: Structural steel cleaning, bridge maintenance

The precision offered by our systems ensures complete contamination removal without affecting the base metal’s dimensional accuracy or surface finish properties.

Wood Surface

Advanced laser technology enables effective wood surface cleaning for restoration and preparation applications. The controlled energy delivery removes surface contaminants while maintaining the wood’s natural characteristics.

Wood Cleaning Applications:

- Heritage Restoration: Historic building maintenance, antique furniture restoration

- Construction: Beam preparation, surface texturing

- Marine Industry: Deck cleaning, yacht maintenance

- Furniture Manufacturing: Surface preparation, finish removal

9. Machine Selection Guide

Pulse vs Continuous Wave Technology

How Pulse Laser Cleaning Works?

Pulse laser cleaning technology operates through controlled energy delivery in discrete time intervals. Each pulse delivers precise energy to the contamination layer, creating rapid thermal expansion that breaks the bond between contaminant and substrate.

How Pulse Laser Cleaning Works?

- Photon Absorption: Target material absorbs laser energy

- Thermal Expansion: Rapid heating causes contamination expansion

- Bond Breaking: Differential expansion breaks adhesion

- Contaminant Removal: Debris ejection through vapor pressure

- Surface Cooling: Rapid cooling prevents substrate damage

Advantages of Pulse Technology Over CW

Precision Control: Pulse parameters allow exact energy delivery matching material properties.

Heat Minimization: Controlled energy input prevents thermal damage to sensitive substrates.

Selective Cleaning: Ability to target specific contamination layers while preserving coatings or treatments.

Material Flexibility: Optimal for heat-sensitive materials including plastics, composites, and delicate metals.

Process Repeatability: Consistent results across production runs with parameter memory.

When to Choose Pulse Laser

✅ Use Pulse When You’re Cleaning:

1. Heat-Sensitive Materials

- Aluminum body panels (automotive)

- Titanium aerospace components

- Carbon fiber composites

- Thin sheet metal (<2mm)

- Why: Pulse keeps substrate <50°C vs CW’s 80-150°C

2. Thin Coatings Requiring Precision

- Paint layers <100μm

- Powder coating

- Oxide layers <50μm

- Selective coating removal (masking not required)

- Why: Precise energy control prevents substrate damage

3. High-Value Parts

- Precision molds ($50,000+ value)

- Turbine blades

- Medical implants

- Historical artifacts

- Why: Zero damage risk vs mechanical/chemical methods

4. Applications Requiring Clean Surface Finish

- Pre-bonding surface preparation (automotive)

- Welding prep (aluminum, stainless)

- Painting/coating prep

- Why: No surface oxidation or roughness

5. Environmentally Regulated Industries

- Food processing facilities

- Pharmaceutical manufacturing

- Clean rooms

- Why: No chemicals, no waste, EPA compliant

When to Choose CW Laser

✅ Use CW When You’re Cleaning:

1. Heavy Rust on Robust Steel

- Rust thickness >300μm

- Structural steel beams

- Railway tracks

- Ship hulls

- Why: CW’s continuous power removes thick contamination faster

2. Large-Area Projects

- Cleaning >50 m²/day

- Stadium structures

- Bridge maintenance

- Industrial flooring

- Why: 2-3x faster cleaning speed than pulse

3. Budget-Constrained Projects

- Initial budget <$5,000

- Simple cleaning requirements

- No precision needed

- Why: CW systems start at $2,000 vs pulse at $3,500

4. Heavy Equipment Maintenance

- Excavator buckets

- Mining equipment

- Agricultural machinery

- Why: Substrate is robust; heat not a concern

Technical Superiority Analysis

| Parameter | Pulse Laser | Continuous Laser | Advantage |

|---|---|---|---|

| Heat Input | Controlled | Continuous | Pulse: Minimal thermal stress |

| Precision | High | Moderate | Pulse: Exact energy delivery |

| Material Damage | Minimal | Possible | Pulse: Non-destructive |

| Energy Efficiency | High | Moderate | Pulse: Optimized power usage |

| Process Control | Excellent | Good | Pulse: Parameter flexibility |

Honest Review: When NOT to Buy a Pulse Laser?

We want you to be happy with your purchase. Do NOT buy a pulse laser machine if:

You are cleaning massive structural steel (e.g., ship hulls, bridges). Pulse lasers are too slow for this; a 2000W CW laser is better.

You have a very low budget (under $3,000). High-quality pulse sources (like JPT MOPA) are expensive components. Cheap alternatives often fail to deliver “non-destructive” results.

Common Power Selection Mistakes to Avoid

❌ Mistake #1: Choosing too low power to save money

- Problem: 100W system takes 8 hours for a job 200W does in 3 hours

- Hidden cost: Labor costs negate equipment savings

- Operator fatigue: Longer cleaning times reduce productivity

- Solution: Calculate true cost per m², not just machine price

❌ Mistake #2: Overkill power “for future needs”

- Problem: 500W system for light rust removal

- Unnecessary cost: 3x higher upfront investment

- Higher operating costs: 8kW vs 2.5kW power consumption

- Solution: Buy what you need now; upgrade later if needed

❌ Mistake #3: Ignoring duty cycle

- Problem: Air-cooled 200W can’t run 8 hours straight

- Downtime: 50% duty cycle = only 4 hours effective work

- Solution: For continuous operation, choose water-cooled 300W+

❌ Mistake #4: Not testing samples

- Problem: Assumed 200W would handle thick industrial paint

- Reality: Needed 300W for acceptable speed

- Solution: Always request sample cleaning before purchase

10. Safety Standards & Compliance

Laser Safety Classifications

Our fiber laser surface cleaner systems comply with international laser safety standards including IEC 60825-1 and FDA CFR 1040.10. All systems are classified as Class 4 lasers with appropriate safety measures.

Safety Classification Details:

- Class 4 Laser System: Highest safety classification

- Maximum Permissible Exposure: Strictly controlled access

- Beam Path Enclosure: Complete containment options available

- Safety Interlocks: Multiple redundant systems

- Warning Systems: Audible and visual indicators

Required Personal Protective Equipment-Chihalo Provide

Laser Safety Glasses

Protective Clothing

Protective Gloves

OD 8+ Laser Helmet

Workspace Safety Requirements

Laser Curtains

Smoke Purifier

Powered Airflow

Laser Sign

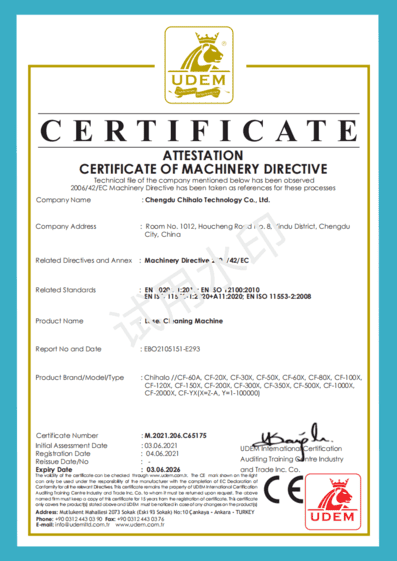

International Certifications

All precision laser cleaning system units carry CE marking indicating compliance with European health, safety, and environmental protection standards.

CE Compliance Standards:

- EMC Directive 2014/30/EU: Electromagnetic compatibility

- Machinery Directive 2006/42/EC: Mechanical safety requirements

11. What You Can Get if Buy From Chihalo?

Standard Components

- Laser Cleaning Machine 1 Unit

- Power Cable 1 Piece

- Protective Lens 5 Pieces

- F-theta Lens 2 Pieces

- OD8+ Laser Goggles 2 Pairs

- Air Box Package

- Cleaning Suit 1 Set

Service & Warranty

- 2 Years of Warranty for all: Laser source, Electronics, Optical Components and Mechanical Componnets.

- System startup and shutdown procedures

- Parameter selection for common applications

- Basic maintenance and troubleshooting

- Safety procedures and emergency protocols

- Email and phone support during business hours

Why Choose Our Pulse Laser Cleaning Systems?

Advanced Technology Leadership

Our commitment to innovation drives continuous technology advancement. MOPA laser technology, advanced scanning systems, and intelligent control software ensure superior performance and reliability.

Comprehensive Product Range

Complete product lineup addresses applications from delicate restoration work to heavy industrial cleaning. Power options from 50W to 2000W, portable to stationary configurations.

Proven Track Record & References

Customer references span aerospace, automotive, marine, manufacturing, and restoration industries. Long-term partnerships with leading companies validate system reliability and support quality.

12. FAQ

Pulse laser cleaning achieves exceptional precision with spot sizes ranging from 0.1mm to 10mm diameter. Energy density control within ±2% enables selective cleaning of individual layers without affecting underlying materials. Scanning systems provide positioning accuracy to ±0.01mm, ensuring consistent results across complex geometries.

Routine maintenance involves weekly optics cleaning, monthly protective glass inspection, and quarterly calibration checks. Annual service includes laser source inspection, cooling system maintenance, and software updates. Typical maintenance costs represent less than 5% of operational expenses with proper care.

When properly configured, pulse laser cleaning is non-destructive to base materials. The selective energy delivery targets contaminants while preserving substrate integrity. Thermal penetration depth is typically less than 10 micrometers, preventing heat-affected zone formation in most applications.

Pulse laser cleaning effectively removes most organic coatings including paints, primers, adhesives, and sealants. Removal efficiency depends on coating thickness, composition, and adhesion strength. Multi-layer systems may require multiple passes or parameter adjustments for complete removal.

Pulse laser cleaning excels with delicate materials through precise energy control and minimal heat input. Thin substrates, precision components, and historical artifacts benefit from the non-contact, low-thermal-impact process. Parameter optimization ensures safe cleaning of materials as thin as 0.1mm.

No. The machine only requires electricity. There are no chemicals, blasting media, or filters to replace frequently. The only "wear part" is the protective lens, which is inexpensive.

Yes! We strongly recommend it. Send us a sample, and we will record a video of the cleaning process and mail the sample back to you for inspection.

When proper safety protocols are followed, health risks are minimal. Primary concerns include eye exposure (prevented by safety glasses), skin exposure (prevented by protective clothing), and fume inhalation (controlled by ventilation). Training and adherence to safety procedures eliminate operational health risks.

Basic operation requires 8 hours of safety and operational training. Advanced applications require 16-40 hours of specialized training. Certification programs ensure operators understand safety procedures, parameter optimization, and emergency protocols. Annual refresher training maintains safety competency.

Power selection depends on contamination type, material thickness, cleaning speed requirements, and quality standards. Light contamination requires 50-200W, moderate contamination needs 200-500W, and heavy contamination may require 500W+. Application testing determines optimal power levels for specific requirements.

Standard warranty covers 24 months on laser sources and major components with 12 months on optics. Extended warranty options provide up to 60 months coverage. Technical support includes phone and email assistance, remote diagnostics, and on-site service. Training and installation are included with all systems.

ROI typically ranges from 12-24 months depending on application and utilization. Labor savings, elimination of consumable costs, and improved productivity drive rapid payback. High-utilization applications may achieve ROI in 6-12 months, while specialty applications average 18-30 months.

Hi! I am Dawn. With 10 years of field experience, I specialize in laser cleaning systems—from optical sourcing to automation. I write here to turn complex specs into actionable buying guides.

Get Your Custom Laser Cleaning Solution Today

Ready to Transform Your Cleaning Process?

Join 1000+ satisfied customers who chose Chihalo industrial laser cleaning machines for superior results. Get personalized consultation from our laser technology experts and discover the perfect solution for your specific application.