50W Portable Laser Cleaning Machine | Precision Rust & Paint Removal | Chihalo OEM Factory

The CHL-M50 is a portable, air-cooled pulsed fiber laser designed for non-destructive cleaning.

- True 50W Max Power: No fake specs. Stable energy output for 100,000+ hours.

- Zero Substrate Damage: Perfect for molds, auto restoration, and stone cleaning.

- Portable Design: Lightweight backpack style (~5kg total) for outdoor work.

- Ready to Ship: 3-7 Working days delivery

- Zero chemical pollution, in compliance with environmental regulations

- One-time investment, long-term zero consumable cost

- Precise control without damaging the substrate

- Portable design, adaptable to various working environments

1. Parameters of 50W Laser Cleaner

|

Model

|

CHL-20S

|

CHL-30S

|

CHL-50S

|

|---|---|---|---|

|

Operation Mode |

Pulse |

Pulse |

Pulse |

|

Laser Power |

20W |

30W |

50W |

|

Wavelength |

1064nm |

1064nm |

1064nm |

|

Pulse Energy |

0.7mJ |

1.0mJ |

1.1mJ |

|

Beam Quality |

≤1.6 |

≤1.6 |

≤1.6 |

|

Pulse Range |

80~110ns |

80~110ns |

80~110ns |

|

Frequency Range |

27~62kHz |

30~60kHz |

45~170kHz |

|

Fiber Cable |

1.9m |

1.9m |

3m |

|

Cooling System |

Air Cooling |

Air Cooling |

Air Cooling |

|

Scaning Length |

<100mm |

<100mm |

<100mm |

|

Storage Temperature |

-10 ~60℃ |

-10 ~60℃ |

-10 ~60℃ |

|

Work Temperature |

0-40℃ |

0-40℃ |

0-40℃ |

|

Machine Size & Weight |

450*250*520mm & 25KG |

450*250*520mm & 25KG |

450*250*520mm & 25KG |

|

Input Power |

220V 50-60Hz |

220V 50-60Hz |

220V 50-60Hz |

|

Power Consumption |

220W |

260W |

340W |

2. What Can a 50W Laser Clean? (Applications)

Industrial Applications:

Injection mold cleaning

Weld seam pre-treatment

Aerospace component degreasing

Restoration & Hobbyist:

Classic car rust removal

Graffiti removal from stone/brick

Coin and antique restoration

3. Is a 50W Laser Cleaner Right for You? The Honest Truth.

We believe in selling the right tool for the job. 50W is not a magic wand for everything.

✅ BUY THIS if you need:

Precision: Cleaning injection molds, historical artifacts, or thin sheet metal without warping.

Safety: Removing paint/rust without removing the base metal (Non-destructive).

Portability: Carrying the machine up ladders or to remote job sites.

Detail Work: Cleaning small complex parts, engine components, or graffiti.

❌ DO NOT BUY if you need:

Heavy Industry Speed: Stripping thick rust from an entire ship hull or bridge girder (You need 200W+ or CW lasers).

Cutting/Welding: This is strictly for cleaning.

4 Uncut Performance: Real Cleaning Speeds

Don't trust theoretical numbers. Here is what you can expect in real-world scenarios with our 50W unit:

|

Surface Condition

|

Cleaning Speed (Approx.)

|

Effect

|

|---|---|---|

|

Light Surface Rust |

15 - 25 cm²/min |

Completely removed, bright metal exposed. |

|

Heavy Rust / Oxide |

5 - 10 cm²/min |

Requires 2 passes for deep clean. |

|

Paint on Metal |

10 - 15 cm²/min |

Vaporizes paint, leaves primer intact (adjustable). |

|

Oil / Grease |

Instant |

Flash evaporation, dry surface immediately. |

Note: Speed depends on the specific material and laser settings (Frequency/Pulse Width).

5 Why "Pulse" Matters: 50W Pulse vs. 1000W CW

You might see 1000W Continuous Wave (CW) lasers for a similar price. Why choose 50W?

The 50W Pulse Advantage (High Peak Energy): It shoots high-energy “bullets” of light that blast away rust instantly without heating up the part. Result: No damage, no melting.

The CW Risk: Continuous lasers apply constant heat (like a blowtorch). They are fast for thick steel but will warp, melt, and destroy precision parts, car panels, or molds.

For restoration and precision industry, 50W Pulse is the professional standard.

6 ROI Analysis: Laser vs. Sandblasting

Why switch to laser? It pays for itself.

- Consumables: Sandblasting costs $15-30/hour in media. Laser costs $0.10/hour (electricity only).

- Labor & Cleanup: No sand means no cleanup. Save 50% of your labor time.

- Environment: No dust, no noise, no chemical disposal fees.

- Typical Payback Period: 6-9 months for small workshops using it 10 hours/week.

FAQ

Our 50W portable laser cleaner excels in precision cleaning tasks where surface sensitivity matters most. These industrial cleaning systems handle small-area mold cleaning, workshop rust removal, paint stripping, wall surface cleaning, elevated cleaning work, and non-metallic contaminant removal. Cultural heritage specialists particularly value these units for artifact restoration projects where precision control prevents damage to delicate materials.

50W fiber laser cleaners effectively remove various surface pollutants from metal substrates, including rust deposits, oil residues, resin buildup, oxidation layers, and thin coating materials. For non-metallic surfaces, our equipment handles dust accumulation, moss growth, paint removal, and similar light contamination challenges. The selective cleaning process targets unwanted materials while preserving the underlying substrate integrity.

Smart purchasers focus on several critical parameters: laser source brand and model designation, motor quantity, cleaning width coverage, processing speed capabilities, pulse frequency range, operation methodology (handheld versus automated systems), equipment dimensions, total weight, and power supply compatibility. These factors directly impact cleaning efficiency and operational flexibility in your specific industrial environment.

The primary distinction lies in cleaning throughput capacity. 50W laser cleaners suit precision applications and moderate intensity cleaning requirements, while higher wattage systems (100W, 200W, 500W) tackle large-scale operations, heavy rust corrosion, and situations demanding superior processing speeds. Think of it as choosing between a precision scalpel and a power tool - both serve important purposes in different scenarios.

Absolutely not when parameters are correctly configured! 50W laser systems exert minimal impact on most metallic materials due to precise energy control. Operator safety remains paramount - following proper safety protocols with appropriate protective equipment (laser safety glasses, protective clothing) ensures complete personnel protection during laser cleaning operations.

Established manufacturers typically provide 2-year laser source warranties plus lifetime maintenance programs. Chihalo specifically offers comprehensive 2-year equipment warranty with lifetime technical support. Common service scenarios include cleaning head motor replacement, laser source troubleshooting, and component upgrades. Our technical team provides remote assistance and replacement parts supply to minimize equipment downtime.

50W laser cleaning machines feature user-friendly interfaces with pre-configured parameter sets and intuitive control systems. Most operators master basic functions without extensive training periods. Chihalo provides comprehensive training programs including video tutorials and hands-on instruction - typically users achieve operational proficiency within one business day.

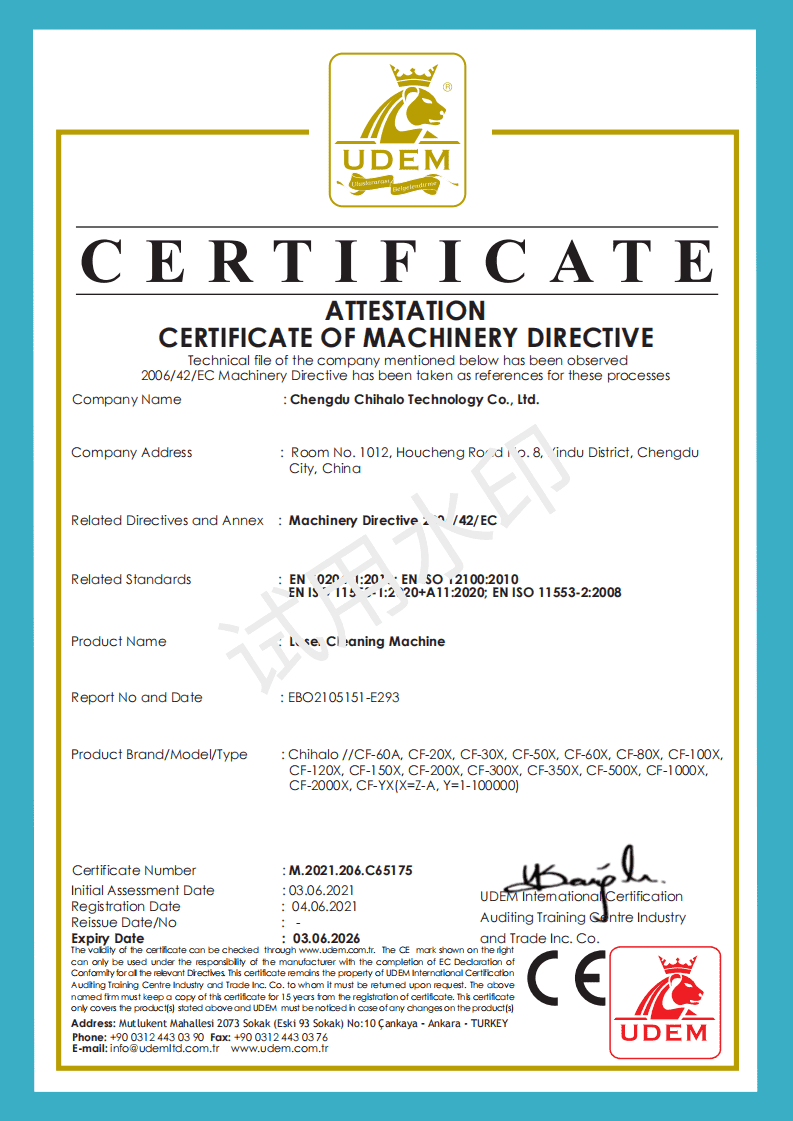

Reputable laser cleaning equipment should carry CE certification, ISO quality standards, and other international safety approvals. Chihalo equipment features dual CE certification - both complete system certification and separate handheld cleaning head certification - providing double compliance assurance for industrial laser cleaning applications.

Chihalo supports customization projects with a minimum order quantity of just 1 unit. Bulk orders of 10+ units qualify for volume pricing. We recommend detailed discussions regarding specific application requirements, logistics arrangements, and after-sales service terms to optimize your laser cleaning investment.

We strongly recommend premium laser source manufacturers like JPT and Max Photonics for superior reliability. These professional-grade laser sources deliver tens of thousands of operating hours with comprehensive manufacturer support networks. Quality laser sources represent the heart of effective cleaning systems.

Smart buyers request cleaning sample demonstrations and performance videos before purchase. Many progressive manufacturers offer free cleaning trials allowing customers to verify actual cleaning effectiveness with their specific materials and contamination types. This hands-on evaluation approach eliminates guesswork from your equipment selection process.

Laser cleaning technology requires minimal consumable supplies - primarily protective lens replacements and electrical power. Annual consumable costs typically remain under $100 USD. Daily maintenance involves simple routine cleaning procedures - no expensive chemicals, abrasive materials, or complex disposal requirements like traditional industrial cleaning methods.

Modern laser cleaning equipment incorporates remote diagnostic capabilities and software upgrade functionality. Our technical support team provides network-based assistance for software updates, parameter optimization, and troubleshooting procedures. This remote support capability dramatically improves service response times and reduces equipment downtime costs.

We use premium fiber sources (like JPT/Raycus/Max) rated for 100,000 hours of service life. That is virtually maintenance-free for over 10 years of daily use.

No. The machine comes with a touchscreen controller and pre-set parameters for common tasks (Rust, Paint, Oil). Most users are operating confidently within 15 minutes. We also provide a 1-on-1 video training call with your purchase.

Yes. The 50W pulse laser is excellent for wood restoration (removing paint/varnish) and stone cleaning (graffiti/soot) because it offers precise control to avoid burning the material.

The package includes the 50W machine, handheld laser gun, safety glasses (essential), protective lens, F-theta lens, foot switch (optional use), and a comprehensive user manual.

Hi! I am Dawn. With 10 years of field experience, I specialize in laser cleaning systems—from optical sourcing to automation. I write here to turn complex specs into actionable buying guides.

Laser Cleaning Device: Buyer’s Guide & Best Machines Compared [2026]& Coating Removal

Laser Cleaning Device: Buyer’s Guide & Best Machines Compared [2026] get a quote Table of Contents A laser cleaning device uses focused high-energy laser beams to strip rust, paint, oil, and other contaminants off metal and other surfaces—no chemicals, no sandblasting, no physical contact with the material. These machines have become the go-to solution for […]

Laser Cleaning Applications: 15+ Industries & Use Cases [2026 Guide]

Laser Cleaning Applications: 15+ Industries & Use Cases [2026 Guide] get a quote Table of Contents What Are Laser Cleaning Applications? Laser cleaning applications refer to industrial processes that use focused laser energy to remove surface contaminants—including rust, paint, oxides, oils, and coatings—without damaging the underlying material. Primary applications include: Rust and corrosion removal from […]

Fiber Laser for Rust Removal: A Practical Buyer’s Guide

Fiber Laser for Rust Removal: A Practical Buyer’s Guide get a quote Table of Contents What 15 Years of Surface Prep Experience Taught Me About Laser Cleaning ”I’ve spent fifteen years helping machine shops, auto restorers, and manufacturers figure out the best way to clean metal. When fiber laser rust removal started getting attention a […]

Cheap Laser Cleaning Machine: 7 Best Budget Picks 2025 (We Tested 12 Models)Guide

Cheap Laser Cleaning Machine: 7 Best Budget Picks 2026 (We Tested 12 Models) get a quote Table of Contents A cheap laser cleaning machine is a budget-friendly industrial tool that uses pulsed fiber laser technology to remove rust, paint, and contaminants from metal surfaces, with prices starting from $1,999 for 20W models and $2,500-$5,000 for […]

Laser Corrosion Removal: How It Works, Costs & Applications [2026 Guide]

Laser Corrosion Removal: How It Works, Costs & Applications [2026 Guide] get a quote Table of Contents Rust and corrosion cost global industries over $2.5 trillion annually in equipment damage, maintenance, and replacement. Traditional removal methods—sandblasting, chemical stripping, and mechanical grinding—create toxic waste, damage surfaces, and slow down production lines. There’s a better way. Laser […]

10 Best Laser Rust Removal Machines in 2025

10 Best Laser Rust Removal Machines in 2026 get a quote Table of Contents Quick Summary for Busy Readers If you’re short on time, here’s what you need to know about choosing the best laser rust removal machine in 2026. Category Our Recommendation 🏆 Best Overall 300W Fiber Laser Cleaner – Best balance of power, […]

Ready to Get Started?

Fill out the form below to request a quote or learn more about our customizable laser cleaning solutions. Let’s tailor the perfect system for your needs!