Backpack Laser Cleaning Machine: Portable Laser Cleaner for Rust, Paint & Coating Removal

Dawn Huang

I'm a passionate engineer and the founder of Chihalo Laser Factory. With an M.Sc. from HKU and 10 years in the field, I've mastered the laser craft from the ground up — from selecting parts to automating systems. Here, I translate complex industry updates into actionable knowledge. Join our community to stay ahead!

Table of Contents

Quick Answer: A backpack laser cleaning machine is a portable, wearable pulsed fiber laser system (100W-500W) designed for on-site rust, paint, and coating removal. Weighing only 25kg, it enables single-person operation in outdoor environments, high-altitude locations, and confined spaces. Prices range from $5,500 to $28,000 depending on power level.

Backpack Laser Cleaner Key Specifications:

- Power Options: 100W, 200W, 300W and 500W MOPA Fiber Laser

- Weight: 25kg (17-33 lbs) total system weight

- Cleaning Speed: 3-12 m²/hour for rust removal

- Price Range: $5,500 – $28,000 USD (factory direct)

- Cooling: Air-cooled (no external water chiller needed)

Is a Backpack Laser Cleaner Right for You?

Choose backpack laser cleaner if: You need mobility for field work, access to hard-to-reach areas, outdoor/off-grid operation, or single-person portability.

Choose cart-style laser cleaner if: You need maximum power (1000W+), stationary workshop use, or heavy-duty continuous operation.

Backpack Laser Cleaning Machine Price & Models

Understanding backpack laser cleaner pricing helps you make an informed purchasing decision. Below is a comprehensive breakdown of costs by power level, plus what affects the final price you’ll pay.

Backpack Laser Cleaner Price by Power Level

Power Level | Price Range (USD) | Cleaning Speed | Best For |

100W | $5,500 – $6,500 | 3-5 m²/hour | Light rust, precision work, beginners |

200W | $6,500 – $7,800 | 5-8 m²/hour | General industrial, most popular choice |

300W | $7,800 – $9,000 | 8-12 m²/hour | Heavy rust, thick coatings, high volume |

What's Included in the Backpack Laser Cleaner Price

Standard packages include:

- Main backpack unit with laser source

- Handheld cleaning gun

- Fiber optic cable (5m)

- Control panel

- Power cord

- Laser safety goggles

- F-theta lens.

Optional extras that increase cost:

- Extended fiber cables(1 meter costs USD500)

- Spare protective lenses(Usually USD10)

- F-theta lens option

- Carrying case

Quick Model Comparison: 100W vs 200W vs 300W vs 500W

100W Backpack Laser Cleaner: Best value for light-duty tasks – ideal for small workshops and beginners ($5,500-$6,500)

200W Backpack Laser Cleaner: Most versatile, balances power and portability – recommended for most users ($6,500-$7,800)

300W Backpack Laser Cleaner: High cleaning power in portable form – for demanding industrial applications ($7,800-$10,800)

500W Backpack Laser Cleaner: Maximum cleaning power in portable form – for demanding industrial applications ($2,2800-$2,5800)

💡 Key Takeaway: The 300W backpack laser cleaning machine offers the best balance of price, power, and versatility for most applications. It’s our most popular model.

Backpack Laser Cleaner Power Guide:

100W vs 200W vs 300W vs 500W

Selecting the right power level is the most critical decision when buying a backpack laser cleaning machine. Choose wrong and you’ll either overpay for unnecessary power or struggle with insufficient cleaning capacity.

Power Selection Guide: 3 Questions to Find Your Ideal Wattage

- Light surface rust, thin oxide → 100W sufficient • Moderate rust, paint, oil stains → 200W recommended • Heavy rust, thick coatings, mill scale → 300W required

- Surface-level (light rust, dust, thin oil film) → 100W • Medium (established rust, single paint layers) → 200W • Heavy (deep rust, multiple paint layers, welding residue) → 300W

- Less than 20 m²/day → 100W adequate • 20-50 m²/day → 200W optimal • More than 50 m²/day → 300W necessary

Backpack Laser Cleaning Results: Before & After

See real cleaning results from backpack laser cleaning machines across different applications. These examples demonstrate effectiveness on various contamination types and materials

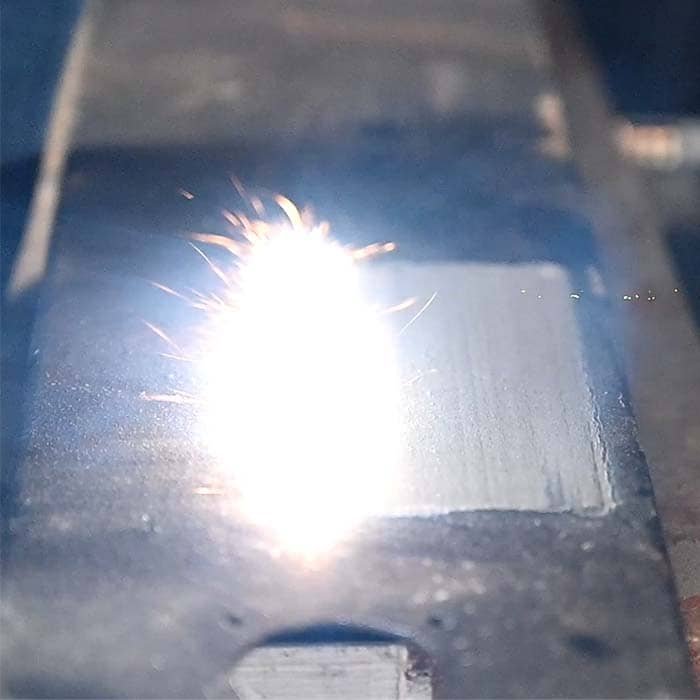

Rust Removal Results

Backpack laser cleaners achieve rust removal speeds of 3-12 m²/hour depending on power level and rust severity. The pulsed laser energy instantly vaporizes iron oxide without damaging the base metal. Results show complete rust elimination with a clean, slightly textured surface ideal for recoating. The non-contact process preserves dimensional accuracy on precision components.

Paint and Coating Removal Results

Laser paint stripping removes single or multiple coating layers with precise control. Unlike chemical strippers, backpack laser cleaning leaves no residue and requires no drying time. Works on automotive paint, industrial coatings, powder coating, and marine anti-fouling paint. Selective layer removal is possible—preserve primer while removing topcoat.

Oil, Grease and Oxide Cleaning Results

Industrial degreasing and oxide removal are achieved rapidly without solvents. The laser vaporizes oil films, machining fluids, and organic contamination instantly. Aluminum oxide, titanium oxide, and weld discoloration are removed efficiently while maintaining surface integrity—ideal for pre-weld preparation and post-weld cleaning.

→ Learn more about [laser rust removal techniques] and best practices.

Why Choose Backpack Laser Cleaner Over Cart-Style Systems?

The backpack form factor transforms laser cleaning from a stationary workshop process into a truly mobile solution. Understanding when portability matters helps justify the investment in a backpack laser cleaning machine.

Laser Cleaner Weight Comparison: Backpack vs. Cart vs. Cabinet

System Type | Total Weight | Mobility Level |

Backpack Laser Cleaner | 25 kg | Single person, any location |

Cart-Style Handheld | 50-80 kg | Wheeled, flat surfaces only |

Cabinet/Stationary | 200+ kg | Fixed installation |

Where Backpack Laser Cleaners Excel

- Outdoor Job Sites: Bridge maintenance, pipeline cleaning, structural steel refurbishment, outdoor sculpture restoration. No heavy equipment transport or infrastructure setup needed.

- High-Altitude Work: Wind turbine maintenance, transmission tower cleaning, building facade restoration, crane and aerial platform work. Lightweight design enables safe operation at height.

- Confined Spaces: Ship hull interiors, storage tanks, boiler tubes, industrial equipment internals. Access areas impossible for cart-mounted systems.

- Remote Locations: Oil field equipment, mining machinery, agricultural equipment. Battery operation eliminates grid power dependency.

Backpack Laser Cleaner Brand Comparison 2024

Several manufacturers offer backpack-style laser cleaning machines. This comparison helps you evaluate options and understand key differentiators in the market.

Brand | Power | Price | Laser | Warranty | Stock |

Fiber Laser Clean | 100-300W | $5,500-9,000 | JPT/Raycus | 2 years | China/US |

SFX Laser | 100-200W | $6,200-8,000 | JPT | 1-2 years | US/Canada |

MCWlaser | 100-200W | $5,800-7,500 | JPT | 1 year | China/US |

DPLASER | 100-300W | $5,500-8,500 | JPT/Raycus | 2 years | China |

AccTek | 100-300W | $5,600-8,600 | JPT | 2 years | China |

Key factors to compare: Laser source brand and warranty, local stock availability (affects shipping time and cost), technical support responsiveness, spare parts availability, and total landed cost including shipping and import duties to your country.

Backpack Laser Cleaning Machine Technical Specifications

Complete Specification Sheet

Parameter | Specification |

Laser Type | Pulsed Fiber Laser (Q-switched or MOPA) |

Wavelength | 1064 nm |

Power Output | 100W / 200W / 300W / 500W (selectable) |

Pulse Frequency | 1-4000 Hz (adjustable) |

Pulse Width | 2-500 ns (model dependent) |

Scanning Width | 0-200mm (lens dependent) |

Focal Distance | 160-750mm |

Fiber Cable Length | 5m standard; 10m/15m optional |

Cooling Method | Air cooling (built-in fans) |

Power Supply | AC 110V/220V or DC 48V battery |

Operating Temperature | 5-40°C (41-104°F) |

Operating Humidity | <85% non-condensing |

Machine Weight | 25kg (power dependent) |

Cleaning Head Weight | 0.9kg |

Laser Source Lifespan | >100,000 hours |

Laser Source Options: JPT vs. Raycus vs. MAX

JPT is the most common choice for backpack laser cleaners, offering excellent pulse control through MOPA technology. Raycus provides reliable Q-switched sources at competitive prices. MAX offers premium options with advanced features. All three brands deliver similar cleaning performance—selection typically depends on price point, warranty terms, and regional service availability.

Key Specs Explained for Beginners

- Pulse Frequency (Hz): More pulses per second = faster cleaning but more heat. Lower frequency with higher energy per pulse works better for heavy contamination.

- Scanning Width: Width of the cleaning path per pass. Wider = faster coverage but may reduce precision on detailed work.

- Focal Distance: Optimal working distance between cleaning head and surface. Maintaining correct focus ensures maximum efficiency.

Backpack Laser Cleaner Applications by Industry

The backpack design enables applications where traditional laser cleaners cannot operate.

These scenarios specifically leverage portable laser cleaning advantages:

Field Maintenance and Outdoor Operations

Bridge rust removal and structural steel maintenance require bringing equipment to the worksite. Backpack laser cleaners enable technicians to access bridge girders, connection points, and structural elements without scaffolding. Pipeline maintenance crews clean weld joints and surface corrosion at remote locations. Construction equipment receives on-site rust treatment during downtime.

Elevated and High-Altitude Work

Wind turbine maintenance teams clean nacelle components and tower sections at height. Transmission tower maintenance includes rust removal from steel structures. Building facade restoration benefits from lightweight design when operating from aerial platforms or scaffolding.

Confined Space Applications

Ship ballast tanks, cargo holds, and engine rooms present access challenges that backpack systems solve. Industrial storage tanks and pressure vessels require internal cleaning. Boiler tube cleaning and heat exchanger maintenance benefit from the compact, wearable design.

Mobile Service and Multi-Site Operations

Automotive restoration shops offering mobile rust removal services. Marine service providers cleaning boat components dockside. Industrial maintenance contractors serving multiple client facilities. Cultural heritage restorers working at monument and artifact locations.

→ Explore more [laser cleaning applications] across industries.

How to Use a Backpack Laser Cleaning Machine

Setup and Preparation

Unbox and inspect all components for shipping damage. Connect fiber optic cable between backpack unit and cleaning head (ensure secure coupling). For AC operation, connect power cord to appropriate voltage supply. For battery operation, install charged battery pack. Power on control panel and allow 30-60 seconds for system initialization.

Parameter Settings for Different Materials

Most backpack laser cleaners include pre-programmed cleaning modes: Mode 1-2 for light rust and oxide, Mode 3-4 for paint removal, Mode 5-6 for heavy rust and scale, Mode 7-8 for oil and grease. Start with lower power settings and increase as needed. Always test on an inconspicuous area first.

Safety Requirements

- Always wear laser safety goggles rated for 1064nm wavelength (OD5+ recommended)

- Work in well-ventilated areas or use fume extraction for heavy cleaning

- Establish controlled area and keep bystanders at safe distance

- Never point cleaning head at people, reflective surfaces, or eyes

- Follow local laser safety regulations and workplace safety requirements

Maintenance and Care

Clean protective lens regularly (inspect before each use, replace when damaged). Keep fiber optic cable free from sharp bends and physical damage. Store in dry environment away from dust and moisture. Schedule annual professional inspection for optimal performance.

Backpack Pulsed Laser vs. Continuous Wave Laser Cleaners

Understanding the difference between pulsed and continuous wave (CW) laser cleaning helps you choose the right technology for your application.

How Pulsed Laser Cleaning Works (Backpack Systems)

- Pulsed fiber lasers deliver high peak power in short bursts, enabling efficient cleaning with minimal heat buildup. This makes them ideal for air-cooled backpack designs. The pulsed approach provides excellent precision and is gentler on substrates—suitable for delicate parts, precision components, and applications requiring zero thermal damage.

How Continuous Wave (CW) Laser Cleaning Works

- CW lasers provide constant beam output at higher average power (1000W-3000W). They require water cooling and heavier infrastructure. CW systems excel at heavy-duty industrial cleaning with maximum throughput but sacrifice portability. Best for stationary workshop installations, production line integration, and high-volume operations.

When to Choose Each Type

- Choose Pulsed Backpack Laser Cleaner: Field work, portability required, precision cleaning, heat-sensitive substrates, light to medium contamination, confined spaces.

- Choose CW Cart-Style Laser Cleaner: Workshop use, heavy contamination, maximum cleaning speed, stationary applications, production environment, thick coatings.

→ Compare our full range of [handheld laser cleaning machines] including both pulsed and CW models.

Backpack Laser Cleaner Customer Reviews & Case Studies

Case Study 1: Maritime Maintenance Company

Industry: Ship repair and maintenance (Singapore)

Challenge: Rust removal in ship hull interiors and confined engine spaces. Sandblasting was time-consuming, created hazardous dust, required extensive cleanup.

Solution: 200W backpack laser cleaning machine for confined space access.

Results: 50% reduction in cleaning time, elimination of abrasive media costs ($3,000/year saved), improved worker safety, zero substrate damage.

Case Study 2: Automotive Restoration Shop

Industry: Classic car restoration (California, USA)

Challenge: Needed to remove rust from classic car frames and body panels without warping thin metal.

Solution: 100W backpack laser cleaner for precision work and mobility around vehicles.

Results: Zero heat warping on thin panels, 60% faster than chemical stripping, customers impressed with surface quality. Now offering mobile rust removal services.

Why Buy Your Backpack Laser Cleaning Machine From Chihalo Laser

Factory-Direct Pricing

- As a direct manufacturer partner, we eliminate distributor markups and offer competitive factory pricing starting from $5,500. Transparent pricing with no hidden fees—the quote you receive is the price you pay (excluding shipping and applicable duties).

Quality Certifications

- All backpack laser cleaning machines carry CE certification for European compliance and FDA registration for US market requirements. Laser sources (JPT, Raycus) meet IEC 60825-1 safety standards. Each unit undergoes 72-hour burn-in testing before shipment.

Warranty Coverage

- 2-year warranty on complete machine

- 2-year warranty on laser source

- Lifetime technical support via WhatsApp, email, phone

- Fast spare parts shipping worldwide (3-7 days)

Global Shipping and Import

- We ship worldwide via sea freight and air express. Delivery: 5-7 days by air, 25-35 days by sea. We provide customs documentation support, HS code information (8456.10), and assist with import requirements for your country. DDP (Delivered Duty Paid) shipping available for US and EU customers.

About Chihalo Laser

Established in 2016, Chihalo Laser Clean has supplied laser cleaning equipment to over 2,000 customers in 45+ countries. Our team includes laser engineers with 10+ years experience in industrial cleaning solutions. We’re committed to providing quality equipment with responsive after-sales support.

Backpack Laser Cleaning Machine FAQ

A backpack laser cleaning machine is a portable, wearable pulsed fiber laser system designed for surface cleaning. It emits high-energy laser pulses that rapidly heat and vaporize contaminants (rust, paint, oxide, oil) while leaving the substrate intact. The backpack design houses laser source, control electronics, and cooling in a wearable unit weighing 8-15kg.

Prices range from $5,500 to $9,000 USD. 100W models: $5,500-$6,500. 200W models: $6,500-$7,800. 300W models: $7,800-$9,000. Price varies by laser source brand, battery options, and accessories included.

100W: Light rust, precision work, <20m²/day. 200W: Moderate rust, general industrial, 20-50m²/day (most popular). 300W: Heavy rust, thick coatings, >50m²/day. Most users find 200W provides the best balance.

Total system: 8-15kg (17-33 lbs) depending on power and battery. Cleaning head: 0.6-0.9kg (1.3-2 lbs). Ergonomic backpack straps distribute weight comfortably for extended work.

Yes, with optional battery pack. 48V lithium batteries provide 40-90 minutes cordless operation. Battery swap takes under 2 minutes. AC power (110V/220V) also supported.

Materials: steel, stainless steel, aluminum, copper, brass, titanium, other metals. Removes: rust, paint, powder coating, oil, grease, oxide layers, mill scale, welding residue. Not recommended for plastics or rubber.

No, when properly configured. Pulsed laser removes contaminants through ablation without significant heat transfer. Adjustable power and frequency optimize for different materials. Non-contact process eliminates mechanical damage.

Laser safety goggles rated for 1064nm (OD5+) are mandatory and included. Also recommended: work gloves, appropriate clothing. Fume extraction advised for heavy cleaning applications.

2-year warranty on complete machine. 2-year warranty on laser source. Covers manufacturing defects and component failures under normal use. Excludes misuse damage, unauthorized modifications, and consumables.

Yes. Free online training via video call, operation manuals, and video tutorials included. Technical support available 24/7 via WhatsApp, email, and phone. On-site training available as paid option.

Laser advantages: no consumables, no dust pollution, no substrate damage, precision control, lower long-term cost. Sandblasting advantages: lower initial cost, faster on very heavy scale. Laser typically achieves ROI in 6-12 months through eliminated consumables.

Quality fiber laser sources (JPT, Raycus, MAX) are rated for >100,000 hours—representing 10+ years of typical use. Unlike CO2 lasers, fiber sources require no gas refills or tube replacements.

Rust removal: 3-5 m²/hr (100W), 5-8 m²/hr (200W), 8-12 m²/hr (300W). Paint removal: ~30-40% slower than rust. Actual speed varies with contamination type, thickness, and surface geometry.

Yes. Send sample materials and we'll perform test cleaning with video documentation showing results. This verifies effectiveness for your specific application before purchase. Contact us to arrange testing.

Get Your Backpack Laser Cleaning Machine Quote

Ready to upgrade your cleaning process with portable laser technology? Contact our team for personalized recommendations and factory-direct pricing.

What happens when you contact us:

- Tell us your application (materials, contamination type, daily volume)

- Receive personalized power level recommendation within 24 hours

- Get detailed quotation with shipping costs to your location

- Optional: Send samples for free cleaning test with video

- Place order and receive machine in 5-35 days (air/sea shipping)

Tell us about your application and we’ll recommend the perfect solution:

Contact Information:

- 📧 Email: [info@chihalo.com]

- 📱 WhatsApp: [+86 18608325040]

Our technical team will respond within 24 hours with personalized recommendations and competitive pricing.