Table of Contents

Are you tired of spending hours manually stripping paint from wood surfaces? A laser paint stripping machine wood can reduce your project time by up to 90% while delivering superior results compared to traditional methods. In 2025, laser technology has revolutionized wood restoration, offering precision, safety, and environmental benefits that chemical strippers and sanding simply cannot match.

This comprehensive guide covers everything you need to know about choosing the best laser paint stripping machine wood, including detailed comparisons, real-world case studies, and expert recommendations to help you make the right investment.

What is a Laser Paint Stripping Machine for Wood?

A laser paint stripping machine wood uses focused laser beams to remove paint, varnish, and coatings from wooden surfaces without damaging the underlying material. Unlike traditional methods, laser technology works by precisely heating the paint layer until it vaporizes, leaving the wood intact and ready for refinishing.

How It Works?

The laser paint removal process involves three key steps:

- Laser Beam Generation: A fiber laser produces a concentrated beam of light energy

- Paint Heating: The beam rapidly heats the paint layer to its vaporization point

- Material Removal: Paint particles are vaporized and extracted via built-in vacuum systems

This non-contact process ensures zero mechanical damage to delicate wood surfaces, making it ideal for antique furniture, architectural millwork, and precision restoration projects.

Key Benefits at a Glance

- ⚡ 90% faster than manual sanding

- 🌱 100% chemical-free and environmentally safe

- 🎯 Precision control preserves wood grain and details

- 💰 ROI payback typically within 6-12 months for professionals

- 🛡️ Safer operation compared to chemical strippers

Why Choose Laser Paint Stripping Machine Wood?

The wood restoration industry has relied on chemical strippers and manual sanding for decades, but these methods come with significant drawbacks:

Traditional Method Limitations

Chemical Stripping Problems:

- Toxic fumes requiring extensive ventilation

- Environmental disposal concerns

- Inconsistent results on different paint types

- Health risks for operators

- Time-consuming neutralization process

Sanding Disadvantages:

- Risk of gouging or damaging wood grain

- Dust particles requiring cleanup

- Physical labor intensity

- Inability to reach intricate details

- Potential for cross-contamination

Laser Technology Advantages

Laser paint stripping machine wood technology offers a myriad of benefits for removing paint from wood, making it a superior choice for a wide range of applications. Here are the key advantages:

Speed & Efficiency

Laser paint stripping machine wood significantly reduces the time and effort required to remove paint from wood surfaces. Unlike manual scraping or chemical methods, laser cleaning technology can quickly and evenly strip paint, drastically cutting down on project time. This efficiency is especially beneficial in commercial settings where time is of the essence, allowing businesses to complete more projects in less time.

Precision & Control

One of the standout features of laser paint stripping machine wood is its precision. Laser paint stripping machines offer adjustable power settings (10-100%) allowing operators to fine-tune intensity for different wood types and paint thicknesses. This precision is impossible with chemical or mechanical methods.

Environmental Benefits

Laser paint stripping machine wood is a greener alternative to traditional paint removal methods. Zero chemical waste and minimal debris make laser stripping the most environmentally responsible choice for wood restoration projects.

Additional Advantages of Laser Paint Stripping Machine Wood

Safety: With no need for chemicals or abrasive materials, laser paint stripping machine wood reduces the risk of accidents and health issues for operators.

Versatility: Laser paint stripping machines wood can be adjusted to suit different types of paint and wood, making them versatile tools for various projects.

Cost-Effectiveness: While the initial investment in Laser paint stripping machines wood technology may be higher than traditional methods, the efficiency and reduced need for consumables make it a cost-effective solution in the long run.

In summary, laser paint stripping machine wood technology represents a leap forward in wood treatment, offering unmatched efficiency, precision, and environmental benefits. Through Chihalo’s customized solutions, businesses can leverage these advantages to achieve superior results while adhering to sustainability and safety standards.

Method Comparison: Laser vs Chemical vs Sanding

| Factor | Laser Paint Stripping | Chemical Stripping | Manual Sanding |

|---|---|---|---|

| Speed | ⭐⭐⭐⭐⭐ (90% faster) | ⭐⭐ (moderate) | ⭐ (very slow) |

| Precision | ⭐⭐⭐⭐⭐ (perfect control) | ⭐⭐ (uneven results) | ⭐⭐ (risk of damage) |

| Safety | ⭐⭐⭐⭐⭐ (minimal risk) | ⭐ (toxic fumes) | ⭐⭐⭐ (dust hazards) |

| Environmental | ⭐⭐⭐⭐⭐ (zero waste) | ⭐ (toxic disposal) | ⭐⭐⭐ (dust particles) |

| Initial Cost | ⭐⭐⭐ ($8,000-25,000) | ⭐⭐⭐⭐⭐ ($50-200) | ⭐⭐⭐⭐⭐ ($20-100) |

| Operating Cost | ⭐⭐⭐⭐⭐ (electricity only) | ⭐⭐ (chemicals + disposal) | ⭐⭐⭐ (sandpaper + labor) |

| Wood Preservation | ⭐⭐⭐⭐⭐ (no damage) | ⭐⭐⭐ (chemical staining) | ⭐⭐ (grain damage risk) |

| Detail Work | ⭐⭐⭐⭐⭐ (intricate patterns) | ⭐⭐ (limited precision) | ⭐ (impossible on details) |

ROI Analysis

Professional Use Case:

- Initial Investment: $6,000 (200W laser system)

- Monthly Projects: 60 furniture pieces

- Time Savings: 75% reduction in labor hours

- Labor Cost Savings: $3,500/month

- Payback Period: 1 month

Premium Laser Paint Stripping Machines Wood

Laser paint stripping machines wood, offered by Chihalo, represent a cutting-edge solution designed to revolutionize the way businesses and craftsmen remove paint and finish from wooden surfaces. Unlike traditional methods that often involve harsh chemicals or abrasive techniques, our Laser paint stripping machines wood provide a precise, clean, and environmentally friendly alternative.

Whether it’s for restoration of cultural relics, automotive paint removal, or preparation of wooden surfaces for refinishing, Chihalo’s Laser paint stripping machines wood are tailored to deliver unmatched performance.

Our Laser Paint Stripping Machine Wood

Chihalo’s laser paint stripping machine wood is at the forefront of surface treatment technology, offering unparalleled precision and adaptability for various applications. Our Laser paint stripping machines wood are designed with the user in mind, incorporating advanced features and customization options to meet the diverse needs of our clients.

Advanced Features

Adjustable Power Settings: Our Laser paint stripping machines wood come equipped with easily adjustable power settings, allowing operators to fine-tune the laser intensity for different paint types and wood densities. This flexibility ensures optimal performance while minimizing the risk of damaging delicate surfaces.

Ease of Handling: Understanding the importance of usability, our Laser paint stripping machines wood are designed for ease of handling. Lightweight and ergonomically designed, they can be operated comfortably for extended periods, reducing operator fatigue and enhancing productivity.

Compatibility with Various Wood Types and Paint Conditions: Chihalo’s laser paint stripping machines’ wood technology is versatile enough to accommodate a broad spectrum of wood types, from soft pine to hard oak, as well as various paint conditions, whether it’s thick layers of old paint or thin, delicate varnishes. Our Laser paint stripping machines wood deliver consistent results, preserving the integrity of the wood beneath.

Customization Options

At Chihalo, we recognize that every business has unique requirements. That’s why we offer extensive customization options for our Laser paint stripping machines wood:

Tailored Sizes: Depending on your project scale and workspace constraints, we can customize the size of our machines to fit your needs. From compact, handheld models for small, intricate work to larger, stationary setups for industrial applications, we ensure that our technology aligns with your operational demands.

Variable Power Levels: To further match our technology to your specific applications, we offer machines with variable power levels. Whether you need a low-power setting for fine, detailed work on sensitive surfaces or a high-power configuration for rapid paint removal on larger areas, our machines can be configured to your specifications.

Application-Specific Design: Recognizing that different industries have different requirements, our R&D team works closely with clients to develop application-specific designs. This might include custom attachments, specialized software for precision control, or adaptations for automated production lines.

Chihalo is committed to providing top-quality, customized Laser paint stripping machines wood that not only meet but exceed our client’s expectations. With our advanced features and customization options, businesses can optimize their operations, ensuring efficiency, precision, and sustainability in all their projects.

Best Laser Paint Stripping Machines Wood 2025

Based on extensive testing and customer feedback, here are the top-rated systems:

1. Chihalo CHL-500W Pro Wood Specialist

⭐⭐⭐⭐⭐ (4.8/5 stars)

Key Features:

- Specialized wood-optimized beam size

- Adjustable focus distance and laser source settings

- Pulse technology for heat control

- Multiple beam patterns

- Suitcase portability design

- Advanced safety features

- Full set of safety parts including fume extraction

- Ergonomic handheld design

- 2-year comprehensive warranty including shipping cost

Price: $19,995 Best For: Professional furniture restoration

Customer Review: “Cut our restoration time by 85%. Paid for itself in 3 months.” – Mike’s Antique Restoration

2. SFX Laser 300W Pulse Wood System

⭐⭐⭐⭐ (4.6/5 stars)

Key Features:

- Pulse technology

- Multiple languages

- Suitcase portability design

- Advanced safety features

- Mobile service friendly

Price: $22,500 Best For: Mobile restoration services

3. STYLECNC Handheld 150W Wood Edition

⭐⭐⭐⭐ (4.5/5 stars)

Key Features:

- Lightweight 18 lb design

- Dual cooling systems

- Wood-specific presets

- Competitive pricing

- Excellent customer support

Price: $15,750 Best For: Small to medium workshops

4. MOZ Laser 250W Professional Wood Cleaner

⭐⭐⭐⭐⭐ (4.7/5 stars)

Key Features:

- Highest precision control

- Premium build quality

- Advanced software interface

- Comprehensive training included

- Industry-leading warranty

Price: $24,995 Best For: High-end restoration specialists

5. Pulsar Laser 1000W Professional Wood Laser Cleaner

⭐⭐⭐⭐⭐ (5/5 stars)

Key Features:

- Highest precision control

- Premium build quality

- Advanced software interface

- Comprehensive training included

- Industry-leading warranty

How Our Technology Supports Your Industry?

Laser paint stripping machine wood technology, especially when applied to wood, offers versatile solutions across various industries. Here’s how Chihalo’s Laser paint stripping machines wood supports different sectors, emphasizing the unique benefits for each:

Furniture Manufacturing and Refurbishing

- Industry Focus: Furniture makers and restorers, including both mass-produced and bespoke items.

- Benefits: Allows for the precise and efficient stripping of paint from wood furniture, preparing surfaces for refinishing. It supports both large-scale manufacturing processes and artisanal refurbishing projects.

Restoration and Conservation

- Industry Focus: Preservation of cultural artifacts, historical buildings, and antique furniture.

- Benefits: Precision and gentle removal of old paint and varnish without damaging valuable wood underneath. Ideal for delicate restorations where maintaining authenticity and integrity is crucial.

Automotive Restoration

- Industry Focus: Restoration of classic wooden-bodied vehicles and detailing on wood interior components.

- Benefits: Offers a non-abrasive method to remove old paint from wooden parts of vintage cars, preserving the original material and preparing it for restoration.

Marine Maintenance

- Industry Focus: Maintenance of wooden boats and ships, including hulls, decks, and interior woodwork.

- Benefits: Effectively removes layers of marine paint and varnish without harming the wood, crucial for both aesthetic and preservation purposes in marine environments.

Construction and Remodeling

- Industry Focus: Renovation of wooden structures, beams, windows, and doors in both residential and commercial properties.

- Benefits: Streamlines the renovation process by efficiently preparing wooden surfaces for repainting or staining, saving time and labor costs.

Art and Sculpture

- Industry Focus: Artists and conservators working with painted wood sculptures and installations.

- Benefits: Enables sensitive cleaning and restoration of painted wood artworks, preserving the artist’s original materials and intent.

Signage and Decor

- Industry Focus: Production and maintenance of wooden signs and decorative elements.

- Benefits: Precise removal of paint allows for easy repurposing or refreshing of signs and decor, supporting sustainable practices and cost savings.

Aerospace

- Industry Focus: Maintenance of wood components in historic and small aircraft.

- Benefits: Safe and precise removal of coatings from wooden parts, essential for restoration and maintenance of airworthiness.

Chihalo’s laser paint removal technology brings unparalleled benefits to these industries, offering a blend of efficiency, precision, and environmental friendliness. By adopting our advanced Laser paint stripping machine wood, businesses can enhance their operations, ensure the longevity of wooden items, and contribute to sustainability efforts. Whether it’s delicate historical restorations or robust manufacturing processes, Chihalo is equipped to meet the diverse needs of industries working with wood.

Wood Type Compatibility Guide

Different wood species require specific laser settings for optimal results, below we would use a 300 MOPA Laser Cleaner as data.

Softwoods

Pine, Fir, Cedar, Spruce

- Recommended Power: 40-60% of maximum

- Speed Setting: Medium (3-5 m/min)

- Special Considerations: Lower heat tolerance, requires careful monitoring

Optimal Settings Table:

| Wood Type | Power (%) | Speed (m/min) | Passes Required |

|---|---|---|---|

| Pine | 45% | 4 | 1-2 |

| Cedar | 40% | 3.5 | 1 |

| Fir | 50% | 4.5 | 1-2 |

Hardwoods

Oak, Maple, Cherry, Walnut

- Recommended Power: 60-85% of maximum

- Speed Setting: Fast (4-7 m/min)

- Special Considerations: Higher heat tolerance, excellent results

Optimal Settings Table:

| Wood Type | Power (%) | Speed (m/min) | Passes Required |

|---|---|---|---|

| Oak | 75% | 6 | 1 |

| Maple | 70% | 5.5 | 1 |

| Cherry | 65% | 5 | 1-2 |

| Walnut | 80% | 6.5 | 1 |

Exotic Woods

Mahogany, Teak, Ebony

- Recommended Power: 50-70% of maximum

- Speed Setting: Slow to Medium (2-4 m/min)

- Special Considerations: Test on hidden areas first

Engineered Woods

Plywood, MDF, Particleboard

- Recommended Power: 30-50% of maximum

- Speed Setting: Slow (2-3 m/min)

- Special Considerations: Risk of delamination, use lowest effective power

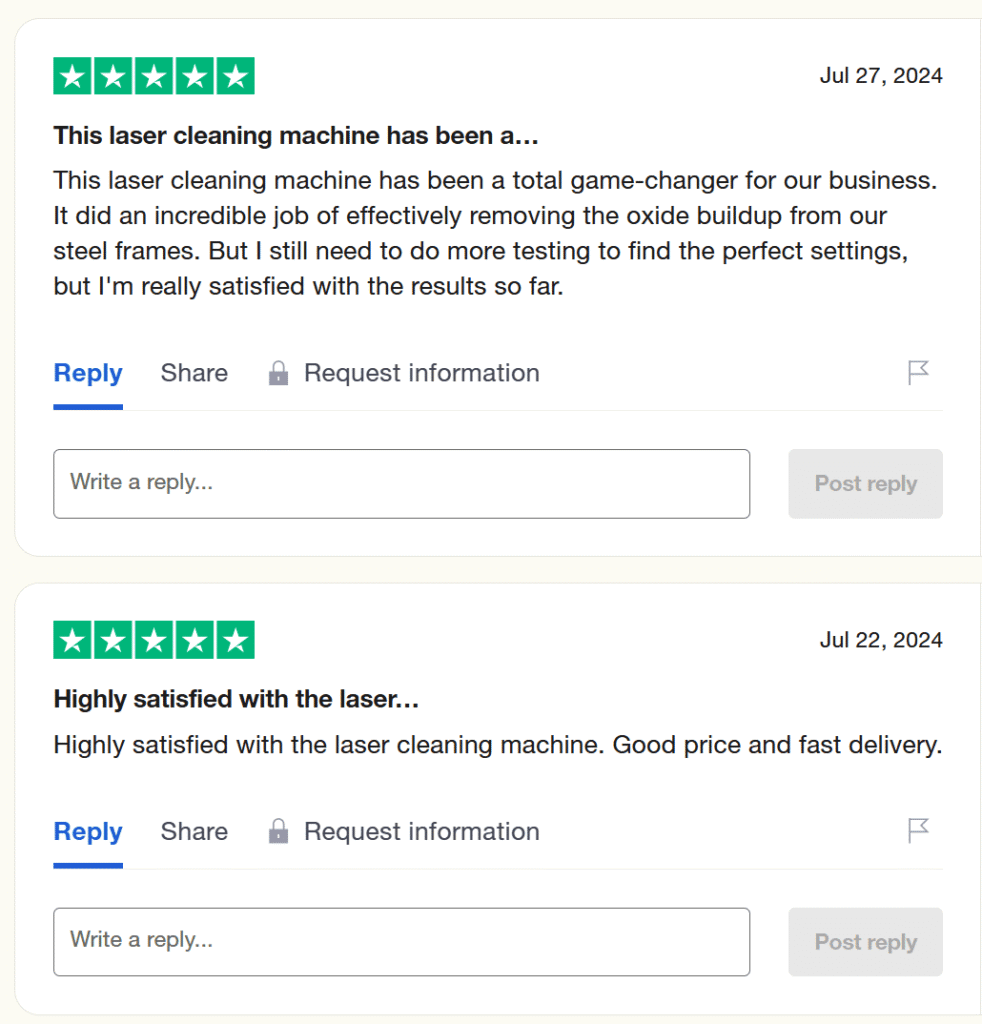

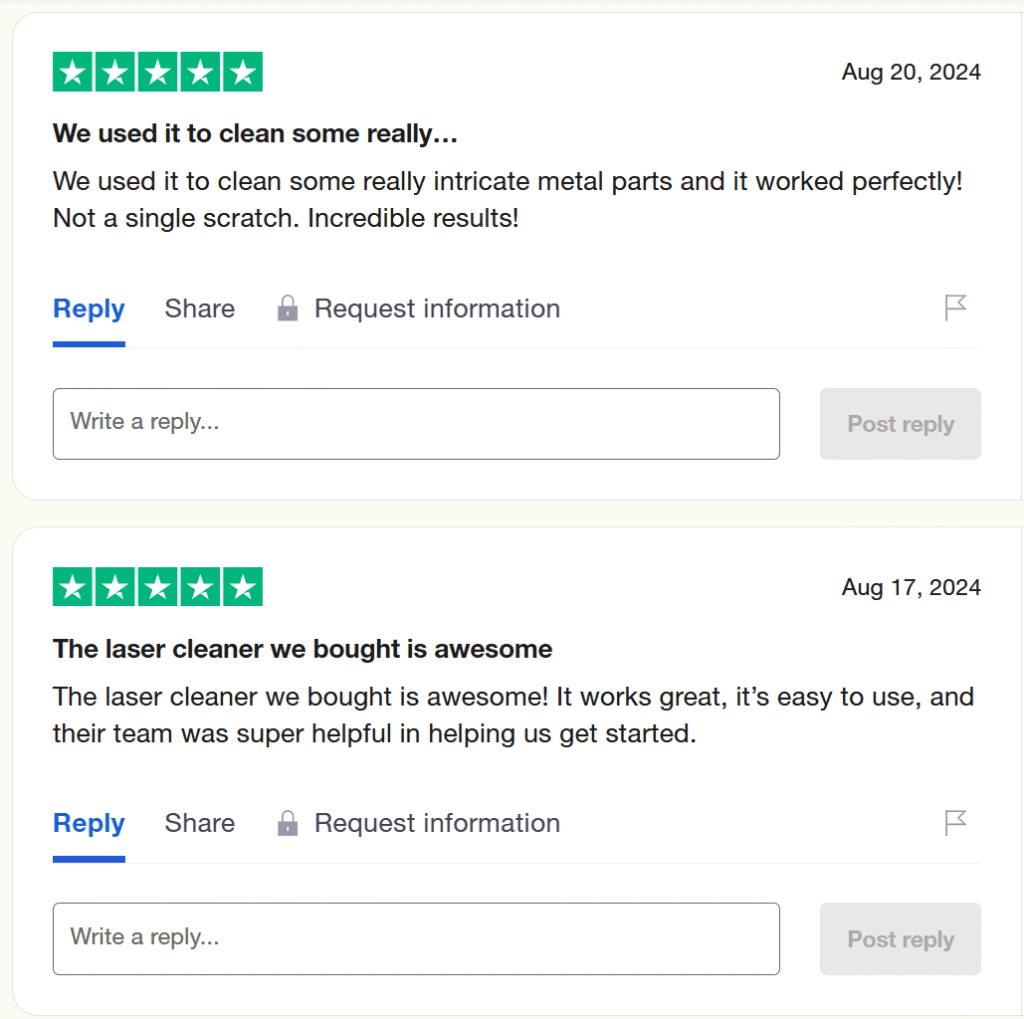

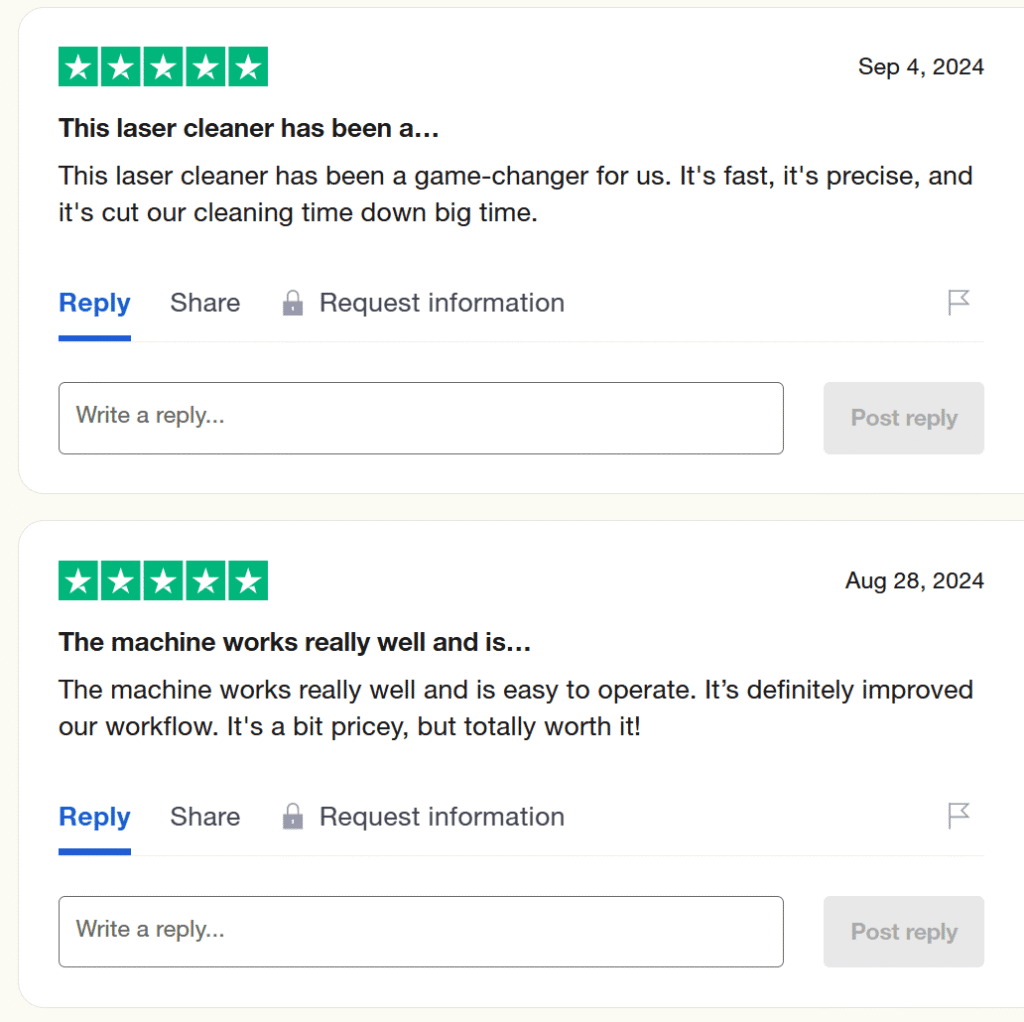

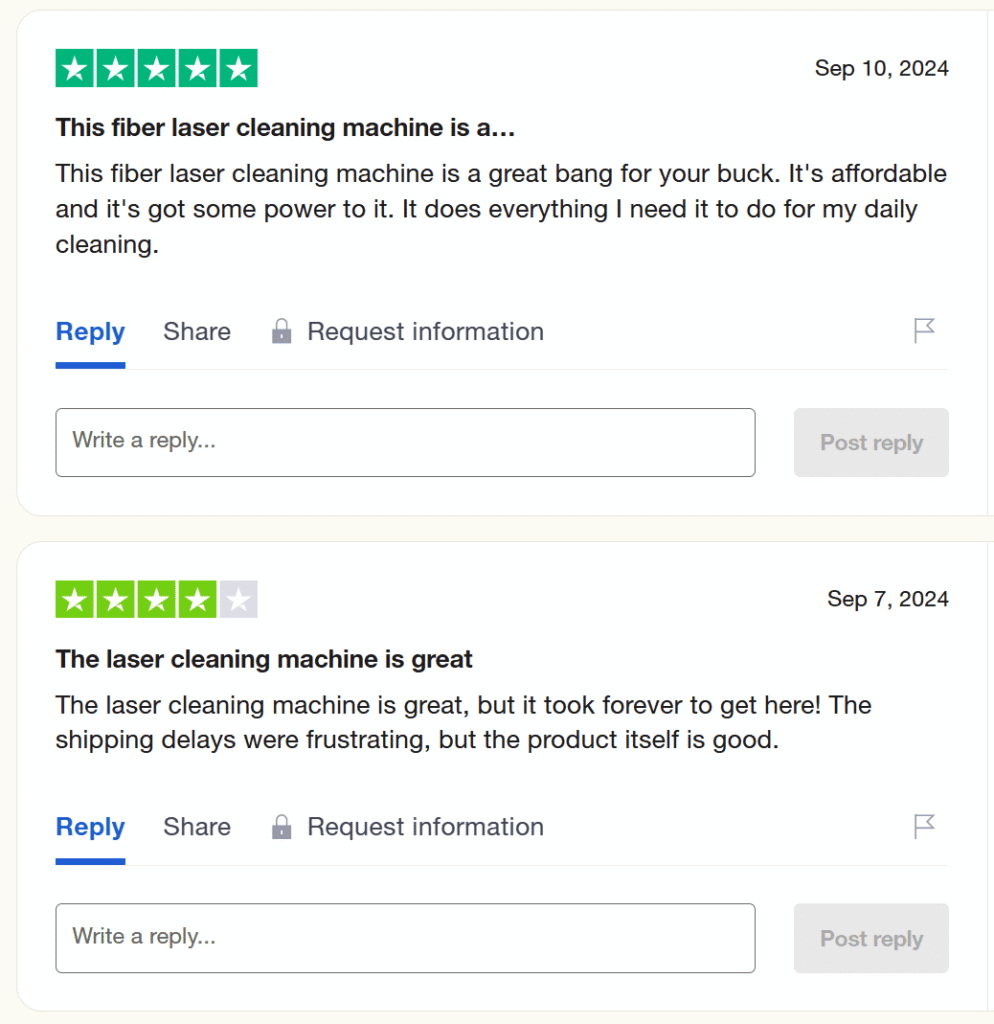

Success Stories and Testimonials

Chihalo’s Laser paint stripping machine wood has transformed operations across various industries, demonstrating the power and precision of our machines. Below, we highlight a few success stories and testimonials from clients who have experienced significant benefits from incorporating our technology into their processes.

Antique Furniture Restoration

Challenge: A restoration company faced difficulties in removing multiple layers of paint from century-old furniture without damaging the underlying intricate wood carvings. Solution: Chihalo's laser paint removal machine was customized with adjustable power settings to delicately remove paint layers, preserving the fine details of the woodwork. Outcome: The furniture was restored to its original glory, showcasing the intricate carvings that were once hidden under paint, significantly increasing its value and historical significance.

Historic Building Renovation

Challenge: A construction firm tasked with renovating a historic building needed a solution to remove aged, lead-based paint from wooden beams and panels without resorting to toxic chemicals. Solution: Utilizing Chihalo's eco-friendly laser technology, the team efficiently stripped away the hazardous paint, ensuring worker safety and compliance with environmental regulations. Outcome: The renovation was completed ahead of schedule, with the wooden structures returned to their natural beauty, contributing to the building's historical authenticity and structural integrity.

Automotive Restoration Workshop

Challenge: A workshop specializing in restoring classic cars struggled with removing old paint from wooden interior trims without damaging the original wood or intricate designs. Solution: They adopted Chihalo’s precision laser technology, capable of targeting the old paint while preserving the delicate underlying surfaces. Outcome: The workshop restored numerous classic cars to their original splendor, with pristine wooden interiors that delighted car enthusiasts and collectors, enhancing the workshop's reputation for quality restoration.

Public Art Project

Challenge: A city council needed to restore a large, painted wooden sculpture located in a public park, where traditional paint removal methods posed environmental and health risks. Solution: Utilizing Chihalo’s environmentally friendly laser system allowed for the paint to be removed without chemicals, protecting the park's ecosystem and visitors. Outcome: The sculpture was restored to its original condition, with the community celebrating the revival of a cherished public artwork. The project served as a model for sustainable art restoration in public spaces.

Safety Guidelines & Requirements

Laser paint stripping machines require proper safety protocols to ensure operator protection:

Personal Protective Equipment (PPE)

- Laser Safety Glasses: Class 4 laser protection (specific wavelength)

- Respiratory Protection: P100 particulate filter mask

- Heat-Resistant Gloves: Kevlar or equivalent material

- Long-Sleeve Clothing: Natural fiber materials (cotton/wool)

- Closed-Toe Shoes: Leather or equivalent protection

Workspace Requirements

Ventilation Standards:

- Minimum 10 air changes per hour

- Local exhaust ventilation at work surface

- HEPA filtration for particle removal

- Carbon filtration for odor control

Fire Safety Measures:

- Class A fire extinguisher within 25 feet

- Smoke detection systems

- Sprinkler protection recommended

- Emergency stop controls accessible

Electrical Safety:

- Dedicated 220V circuit (most systems)

- Ground fault protection required

- Regular electrical inspections

- Proper cable management

Buying Guide: What to Consider

Budget Planning

Total Investment Breakdown:

- Equipment Cost: $8,000 – $50,000

- Safety Equipment: $500 – $1,500

- Installation/Training: $1,000 – $3,000

- First Year Maintenance: $500 – $1,200

- Insurance Adjustment: $200 – $800/year

Financing Options

Equipment Financing:

- Lease Programs: $300-800/month

- Equipment Loans: 4-7% APR typical

- Tax Incentives: Section 179 deduction eligible

- Manufacturer Financing: Often 0% for qualified buyers

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Feature Prioritization Matrix

Essential Features (Must Have):

- Variable power control

- Safety interlocks

- Fume extraction capability

- Manufacturer warranty

- Training included

Important Features (Should Have):

- Multiple beam patterns

- Digital controls

- Portable design options

- Remote monitoring

- Technical support

Nice-to-Have Features:

- Automation capabilities

- Advanced software

- Multiple wavelengths

- Extended warranties

- Loaner equipment programs

F.A.Q.

With a 200W laser system, a standard dining chair takes 15-30 minutes depending on paint layers and detail complexity. Traditional methods typically require 2-4 hours for the same result.

When properly calibrated and operated, laser systems will not damage wood. The technology precisely targets paint layers while leaving wood fibers intact. Always test on inconspicuous areas first.

Laser systems effectively remove most paint types including acrylics, latex, oil-based paints, polyurethane, varnish, stains, and even lead-based paints (with proper safety protocols).

Yes, with proper ventilation and safety equipment. Most systems include built-in fume extraction, and the process produces minimal airborne particles compared to sanding.

Yes, laser technology works on both hardwoods (oak, maple, cherry) and softwoods (pine, cedar, fir). However, different wood types require different power settings - hardwoods can handle higher power levels while softwoods need gentler treatment.

Yes, laser cleaning can effectively remove mold, mildew, and organic growth from wood surfaces. The process also sterilizes the surface, preventing regrowth when combined with proper moisture control.

Laser systems can remove multiple paint layers (typically 3-8 layers) in a single pass, depending on the total thickness and paint types. Very thick coatings may require multiple passes.

Professional systems can clean 2-15 square feet per hour depending on power level, paint thickness, and desired finish quality. Higher power systems naturally work faster.

Most paints respond well to laser treatment. However, some specialized industrial coatings, certain metallic paints, and extremely thick marine coatings may require adjusted settings or multiple passes.

Yes, but floor applications require special considerations including dust extraction, area preparation, and typically handheld systems for maneuverability around room fixtures.

Most professional operations see payback within 6-12 months due to increased efficiency and reduced labor costs. High-volume shops often achieve payback in 3-6 months.

Operating costs are minimal - primarily electricity consumption ($2-5 per hour) and periodic maintenance. No consumables like sandpaper or chemicals are required.

Yes, most manufacturers offer financing options including leases, equipment loans, and 0% financing for qualified buyers. Many purchases qualify for Section 179 tax deductions.

Entry-level handheld systems start around $8,000, professional 200W systems range $6,000-15,000, and high-end industrial systems can reach $30,000+. Price varies by power, features, and brand.

For occasional use, rental might be more economical ($500-1,500/week). However, if you have more than 2-3 projects annually, purchasing often becomes cost-effective.

Power below 500W can be 110V to 220V widely range. Power 1KW to 2KW can be 110V or 220V for option. Power from 3KW are usually 380V.

Handheld systems need minimal space (8'x10' minimum), while larger systems may require dedicated workshop areas. All systems need adequate ventilation connections.

Daily cleaning of optics (2 minutes), weekly system checks (50 minutes), and annual professional service. Most manufacturers provide detailed maintenance schedules and training.

Most professional systems require 220V service and dedicated circuits. Some portable units work with standard outlets. Installation typically requires a qualified electrician.

Pulse lasers deliver energy in short bursts, reducing heat buildup and wood damage risk. Continuous lasers provide constant energy flow for faster processing but require more careful heat management.

Operators need laser safety training covering protective equipment, safe operating procedures, and emergency protocols. Most manufacturers provide comprehensive training programs.

Systems must comply with OSHA laser safety standards and local environmental regulations. Some areas may require permits for commercial use.

Yes, laser systems can safely remove lead paint when proper safety protocols are followed, including enhanced ventilation, HEPA filtration, and personal protective equipment.

Required PPE includes laser safety glasses (wavelength-specific), respiratory protection, heat-resistant gloves, and protective clothing. Never operate without proper eye protection.

When properly operated, fire risk is minimal. Modern systems include safety features like emergency stops and heat monitoring. Always have fire extinguishers available and follow safety protocols.

Yes, handheld laser systems excel at detailed work including carvings, moldings, and curved surfaces that are difficult or impossible with traditional methods.

Basic operation can be learned in a few hours, but achieving professional-level efficiency typically requires 1-2 weeks of practice. Most manufacturers provide comprehensive training programs.

Many dealers offer rental programs for trying equipment or handling large temporary projects. Rental costs typically range from $500-1,500 per week depending on system power.

Can laser stripping be used on painted wooden instruments?

Wind can affect fume extraction efficiency, and moisture can interfere with laser effectiveness. Indoor or covered outdoor conditions are preferred for optimal results.

Yes, but with caution. Engineered woods often contain adhesives that may respond differently to laser treatment. Always test on hidden areas and use lower power settings initially.

Check power settings, ensure proper focus distance, verify lens cleanliness, and confirm you're using appropriate speed settings for the paint type and thickness.

Usually caused by excessive power, slow movement speed, or poor focus. Reduce power settings, increase movement speed, or check focus calibration.

Start with lowest effective power (usually 30-40%) and gradually increase until paint removes cleanly without wood damage. Different paint types and wood species require different settings.

Check emergency stops, power connections, cooling system operation, and lens condition. Most systems have diagnostic displays showing error codes. Consult manufacturer support for complex issues.

No, different paints absorb laser energy differently. Oil-based paints typically need higher power than latex. Always test settings on inconspicuous areas when switching paint types.

A laser paint stripping machine uses high-intensity laser beams to remove paint, varnish, and coatings from wood surfaces. The laser energy is absorbed by the surface layer, vaporizing the unwanted material without damaging the underlying wood.

The machine directs a focused laser beam onto the painted wood surface. The beam’s intensity is carefully controlled to ensure it only removes the paint layer. The laser’s heat vaporizes the paint, which can then be extracted using a vacuum system, leaving the wood surface clean.

- Non-contact process: Minimizes damage to the wood.

- Precision: Targets specific areas without affecting the surrounding material.

- Environmentally friendly: Reduces the use of chemical strippers.

- Efficiency: Speeds up the paint removal process compared to traditional methods.

- Safety: Lowers the risk of exposure to toxic chemicals.

Yes, laser paint stripping machines are effective at removing various types of paint and finishes from wood, including acrylics, enamels, and varnishes. However, effectiveness may vary based on paint thickness, type, and the laser’s settings.

While laser paint stripping is safe for most wood types, the technique’s suitability can vary based on the wood’s density, moisture content, and the specific laser settings used. It’s essential to conduct a test on a small area to ensure the wood is not adversely affected.

Consider the following factors:

- Power and wavelength: Ensure the machine’s specifications match your paint removal needs.

- Working area size: Choose a machine that can accommodate the sizes of wood you work with.

- Portability: If you need to move the machine frequently, look for a model designed for easy transport.

- Manufacturer support: Opt for brands that offer good customer service and technical support.

- Cost: Higher initial investment compared to traditional stripping methods.

- Learning curve: Requires training to operate safely and effectively.

- Maintenance: High-precision equipment may need regular maintenance.

Laser paint stripping machines can be purchased from manufacturers specializing in laser equipment for industrial applications. It’s advisable to conduct thorough research, compare products, and consider post-sale support when making your decision.