All Laser Cleaning Machines

Portable Laser Cleaning Machine

-

Backpack Laser Cleaning Machine

-

Suitcase Laser Cleaning Machine

-

Trolley-Mounted Laser Cleaning Machine

-

Battery-powered Laser Cleaning Machine

Manual Laser Cleaning Machine

-

Enclosed MOPA 1.8mJ Laser Cleaning Machine

-

Enclosed MOPA 100mJ Laser Cleaning Machine

-

CW Laser Cleaning Machine(Water Cooling)

-

CW Laser Cleaning Machine(Air Cooling)

Automated Laser Cleaning Machine

-

Robot Laser Cleaning Machine

-

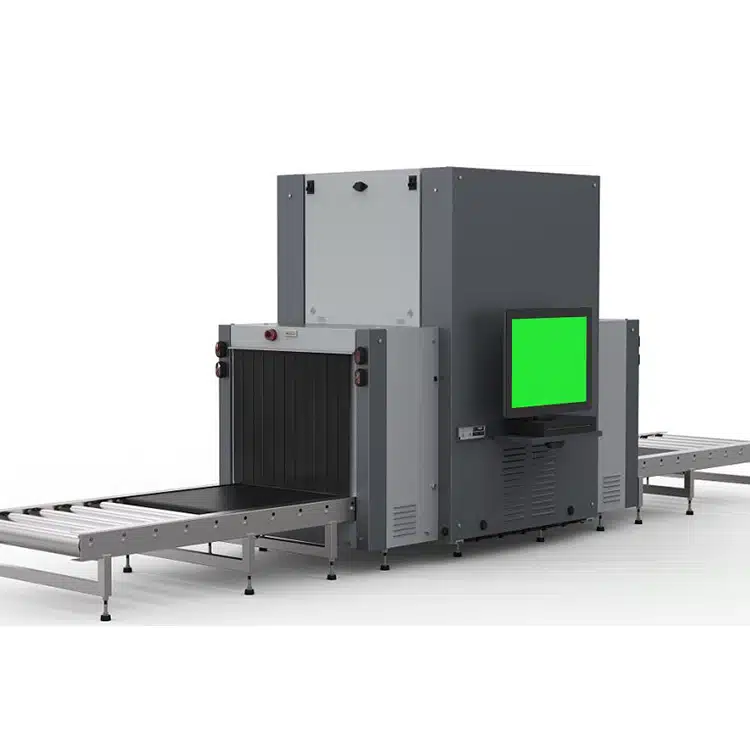

Conveyor Belt Laser Cleaning Machine

-

Gantry Laser Cleaning Machine

-

Swivel Arm Laser Cleaning Machines

-

Vision-Guided Laser Cleaning Machines

-

Multi-Axis Laser Cleaning Machines

OEM Laser Cleaning Machine

-

Software Languages&Logo

-

Chassis Color and Design

-

Remote Cleaning Systems

-

Customized Function Development

1. Introduction to Laser Cleaning Technology

Laser cleaning technology represents a significant advancement in the field of industrial cleaning and surface preparation. Utilizing highly focused laser beams, this method efficiently removes contaminants, coatings, rust, and various deposits from different materials without causing damage to the underlying surface. Its precision and effectiveness have led to its adoption across various industries, including manufacturing, restoration, and maintenance.

The Rise of Laser Cleaning Solutions

Laser cleaning machines have gained popularity due to their numerous benefits and the growing need for environmentally friendly and efficient cleaning methods. This technology emerged as a response to the limitations of traditional cleaning methods, which often involve harsh chemicals, abrasive materials, or significant labor and can be detrimental to the environment, operator safety, and the integrity of the substrate.

The advancement in laser cleaning technology, coupled with the drive towards sustainable industrial practices, has positioned laser cleaning as a highly desirable option. It is particularly appealing in sectors such as cultural relic restoration, automotive paint removal, mold maintenance, and the preparation of surfaces for coating or welding. Businesses, including laser equipment dealers, manufacturers, and restoration specialists, are increasingly incorporating laser cleaning machines into their operations to enhance quality, efficiency, and environmental compliance.

Advantages of Laser Cleaning Over Traditional Methods

Laser cleaning technology offers several advantages over traditional cleaning methods, making it a superior choice for many applications:

Precision and Selectivity

- High Precision: Laser cleaning allows for the precise targeting of contaminants without affecting the underlying material, preserving the integrity of the original surface.

- Selective Removal: It can selectively remove specific layers or types of contamination, which is particularly useful in restoration and maintenance applications.

Environmentally Friendly

- No Chemicals Required: This method eliminates the need for hazardous chemicals, reducing environmental pollution and health risks to operators.

- Minimal Waste Production: Laser cleaning produces minimal waste, as it often vaporizes contaminants, leaving behind a small amount of dust that can be easily collected and disposed of.

Efficiency and Effectiveness

- Fast and Efficient: Laser cleaning is faster than many traditional methods, significantly reducing downtime in industrial processes.

- Effective on Tough Contaminants: It is highly effective in removing tough contaminants like rust, paint, and heavy deposits, often in a single pass.

Safety and Reduced Costs

- Improved Safety: With no need for harsh chemicals or abrasive techniques, laser cleaning improves workplace safety.

- Lower Long-term Costs: While the initial investment may be higher, the efficiency, speed, and reduced consumables lead to lower operating costs over time.

Versatility

- Wide Range of Applications: From delicate artifacts in cultural restoration to robust industrial machinery, laser cleaning is versatile enough to be used in a wide variety of materials and settings.

- Customizable Solutions: Modern laser cleaning systems can be tailored to specific tasks, offering adjustable power levels, spot sizes, and patterns to suit different applications.

Laser cleaning technology continues to evolve, with ongoing research and development aimed at enhancing its capabilities, efficiency, and accessibility. As industries worldwide strive for more sustainable and efficient cleaning solutions, affordable laser cleaning machine stands out as a promising technology that aligns with environmental goals and operational efficiency requirements.

2. Understanding Laser Cleaning Machine Prices

Laser cleaning machines have revolutionized the way industries and individuals approach cleaning and restoration tasks. Its precision, efficiency, and environmental friendliness make it a preferred choice over traditional methods like chemical cleaning or abrasive blasting. However, the cost of laser cleaning machines can vary widely based on several factors. In this guide, we’ll explore what influences the price of these machines and compare the costs between small-scale and industrial laser cleaners.

Factors Influencing the Cost of Laser Cleaning Machines

Power and Performance: The laser’s power output, measured in watts (W), is a primary determinant of price. Higher-powered lasers can tackle tougher jobs and work faster, but they also cost more.

Quality and Durability: Machines built with high-quality components that offer greater durability and longer lifespans typically command higher prices. The reputation of the manufacturer can also affect the cost.

Features and Customization: Additional features such as adjustable power settings, different cleaning heads, or automation capabilities can increase the price. Customization to meet specific industry needs also adds to the cost.

Software and Control Systems: Advanced software for precise control and operation of the laser cleaner can raise the price. User-friendly interfaces and programmability are often worth the investment.

Service and Support: Post-purchase support, including warranty, maintenance services, and customer service availability, can influence the machine’s price. Better support services often mean higher initial costs but can save money in the long term.

Market Demand: As with any product, the principles of supply and demand apply. High demand for laser cleaning machines in certain industries can drive up prices.

Price Comparison: Small-Scale vs. Industrial Laser Cleaners

Small-Scale Laser Cleaners:

- Target Audience: Small businesses, hobbyists, and low-volume cleaning tasks.

- Power Range: Typically up to 100 watts.

- Price Range: From a few thousand to tens of thousands of USD, depending on features and quality.

- Applications: Rust removal, paint stripping from small parts, and restoration of artworks or delicate items.

Industrial Laser Cleaners:

- Target Audience: Large manufacturing plants, automotive industry, aerospace, and high-volume cleaning operations.

- Power Range: 100 watts to over 1000 watts for the most demanding tasks.

- Price Range: Tens of thousands to hundreds of thousands of USD. The price increases significantly for custom systems designed for specific industrial applications.

- Applications: Large-scale rust removal, de-coating large structures, weld cleaning, and preparation of surfaces at an industrial scale.

In summary, the price of laser cleaning machines is influenced by a variety of factors, including their power, quality, features, and the level of support offered by the manufacturer. Small-scale cleaners are significantly less expensive than their industrial counterparts but are also less powerful and suitable for smaller tasks. Understanding these differences is crucial for buyers to make informed decisions that match their needs and budget constraints.

3. Types of Laser Cleaning Machines and Their Pricing

The landscape of laser cleaning technology is diverse, with machines designed to meet a wide range of needs, from delicate restoration projects to heavy-duty industrial cleaning. Two main categories stand out in this market: handheld laser cleaners and automated laser cleaning systems. Each category caters to different applications, offering unique features, advantages, and, of course, pricing structures. Understanding these differences is crucial for making an informed investment.

Handheld Laser Cleaners: Features and Prices

Handheld laser cleaners are renowned for their portability, ease of use, and flexibility. They are ideal for applications requiring precise control, such as removing rust, paint, or contamination from small areas or objects with complex geometries. These units typically range in power from 20 watts to 100 watts, enough to tackle a variety of cleaning tasks without damaging the substrate.

Features:

- Portability: Compact and easy to maneuver, allowing access to hard-to-reach areas.

- Flexibility: Adjustable settings to match different materials and contaminants.

- Ease of Use: Simple interfaces that don’t require extensive training.

Pricing:

Prices for handheld laser cleaners can vary significantly based on power, brand, and additional features. Entry-level models start around $10,000 to $15,000, while more powerful and feature-rich models can exceed $30,000. The investment aligns with the machine’s versatility and the cost savings from non-abrasive, chemical-free cleaning.

Automated Laser Cleaning Systems: Advantages and Investment

Automated laser cleaning systems are designed for larger-scale operations that require consistent, high-speed cleaning. These systems are often integrated into manufacturing lines for tasks like surface preparation, de-coating, or cleaning before welding. They offer higher power outputs, from 100 watts to over 1000 watts, to handle extensive cleaning tasks more efficiently.

Advantages:

- Efficiency: High-speed cleaning that significantly reduces operation time.

- Consistency: Uniform cleaning results with minimal human intervention.

- Integration: Easily integrated into existing manufacturing processes.

Investment:

The cost of automated laser cleaning systems reflects their industrial capabilities and the technology involved. Prices start from around $50,000 for basic setups and can go up to several hundred thousand dollars for high-power, fully automated systems with advanced features like robotic arms and custom software.

Making the Right Choice

Deciding between handheld and automated laser cleaning machines involves considering your specific cleaning needs, budget constraints, and long-term objectives. Handheld models offer flexibility and lower initial costs, making them suitable for smaller operations or as a supplement to traditional cleaning methods. On the other hand, automated systems, while requiring a higher upfront investment, provide unmatched efficiency and consistency for high-volume or industrial applications. The right choice depends on the balance between these factors and the anticipated return on investment.

4. How Laser Power Affects Machine Price

The price of laser cleaning machines is significantly influenced by their laser power, among other factors. Laser power, measured in watts, dictates the machine’s ability to perform various cleaning tasks, from delicate surface treatment to the removal of tough coatings and contaminants. Understanding the relationship between power ranges and their impact on price, as well as how to balance power and price for specific needs, is essential for making an informed purchasing decision.

Power Ranges and Their Impact on Price

Low-Power Laser Cleaners (20W – 100W):

Low-power laser cleaners are typically handheld or portable units designed for light cleaning tasks, such as removing rust, paint, or dirt from sensitive surfaces. The lower power range means these machines consume less energy and are less expensive to manufacture, resulting in lower prices for the end-user. Prices for these units can range from $10,000 to $30,000, depending on additional features and the specific manufacturer.

Medium-Power Laser Cleaners (100W – 500W):

Medium-power laser cleaning machines offer a balance between performance and cost, suitable for a wider range of applications, including more demanding cleaning tasks. These machines can be either handheld or part of automated systems. With the increase in power, the price also rises, reflecting the higher production costs and the machine’s enhanced capabilities. Prices for medium-power laser cleaners generally range from $30,000 to $100,000.

High-Power Laser Cleaners (500W and above):

High-power laser cleaners are designed for the most demanding industrial applications, including heavy paint removal, de-coating large areas, and preparing surfaces for welding or coating. These systems are typically part of automated setups, featuring advanced technology that ensures precision and efficiency. The high power output requires sophisticated cooling systems and safety features, contributing to higher manufacturing costs. Consequently, high-power laser cleaning machines can cost anywhere from $100,000 to several hundred thousand dollars.

Balancing Power and Price for Your Needs

When considering the purchase of a laser cleaning machine, it’s important to evaluate your specific cleaning requirements against the cost of the machine. Here are some tips to help balance power and price:

Assess Your Cleaning Tasks: Define the type of contaminants you need to remove, the materials you’ll be working with, and the precision required. This assessment will help determine the minimum power needed for your applications.

Consider Efficiency and Productivity: Higher-power machines can complete cleaning tasks faster and may be more cost-effective in the long run for high-volume or industrial applications.

Evaluate Long-Term Costs: Besides the initial purchase price, consider the long-term operational costs, including power consumption, maintenance, and potential downtime. Sometimes, investing in a more powerful machine can lead to lower overall costs due to increased efficiency and durability.

Seek Professional Advice: Manufacturers and suppliers can provide valuable insights into the best balance of power and price for your specific needs. They can also offer demonstrations or samples to help you make an informed decision.

Choosing the right laser power for your cleaning machine involves weighing the initial investment against the operational benefits. By carefully considering your needs and consulting with professionals, you can select a laser cleaning machine that offers the best value and performance for your investment.

5. Key Features That Influence Laser Cleaning Machine Prices

When it comes to laser cleaning machines, several key features significantly influence their prices. Two of the most impactful are customization options and the combination of durability and warranty offered by the manufacturer. These factors not only affect the initial cost of the equipment but also contribute to its long-term value and operational efficiency.

Customization Options and How They Affect Costs

Customization is a critical factor that can drive up the price of laser cleaning machines. The ability to tailor a machine to specific operational needs allows for more efficient and effective cleaning processes but comes at a premium. Here are some common customization options that influence cost:

- Laser Power Adjustment: Machines that offer a wide range of power settings can handle a variety of materials and contaminant levels, making them more versatile and, consequently, more expensive.

- Wavelength Customization: Different cleaning tasks may require different laser wavelengths. Machines capable of operating at multiple wavelengths to accommodate various applications are pricier due to their advanced technology.

- Integration Capabilities: The ability to integrate the laser cleaning system into existing production lines or with other machinery can significantly increase its value and price. This includes compatibility with robotic arms, conveyors, and custom software solutions.

The extent of customization directly impacts the price, reflecting the complexity and versatility of the machine. While higher upfront costs might seem daunting, the long-term benefits of a customized solution often justify the investment through improved efficiency and productivity.

Durability and Warranty: Long-Term Value Considerations

The build quality, durability, and warranty coverage of a laser cleaning machine are significant indicators of its long-term value and reliability. High-quality construction and materials ensure the machine can withstand the rigors of intensive use, particularly in industrial environments.

- Durability: Machines designed with robust materials and construction techniques offer greater durability, which is essential for minimizing downtime and maintenance costs. However, this durability comes at a higher initial cost.

- Warranty: A comprehensive warranty can add considerable value to a laser cleaning machine purchase. Manufacturers that offer extensive warranties typically stand behind the quality of their products. Warranty coverage that includes parts, labor, and software support minimizes potential repair costs and ensures the machine operates at peak efficiency for longer.

Investing in a machine that prioritizes durability and comes with a strong warranty might require a higher upfront cost but can lead to significant savings over time. Reduced maintenance requirements, fewer operational interruptions, and the peace of mind that comes from knowing future issues will be covered are valuable benefits that contribute to the overall return on investment.

6. Laser Cleaning Machine Applications and Pricing

Laser cleaning technology has revolutionized how industries and preservation efforts approach the cleaning and restoration of various surfaces. Its non-contact, precise, and efficient method offers significant advantages over traditional methods, particularly in fields such as cultural heritage restoration and the automotive industry. The application in these sectors not only dictates the type of laser cleaning machines used but also significantly influences their pricing.

Cultural Heritage Restoration: Specialized Equipment Costs

In the realm of cultural heritage restoration, the primary focus is on the delicate and precise removal of contaminants without damaging the underlying material. Artifacts, historic buildings, and artworks require a gentle touch, often necessitating low power settings and very fine control.

Specialized Equipment Costs: The laser cleaning machines suited for this sector are typically equipped with advanced features such as fine control over pulse duration and wavelength, which are critical for ensuring the preservation of delicate substrates. Given the specialized nature of these machines, their costs are generally higher than standard models. Prices can range significantly based on the customization and specifications required, often reaching upwards of $50,000 to $100,000 for systems that offer the level of control and safety needed for heritage conservation.

Automotive Industry: Solutions for Paint Removal and Restoration

The automotive sector utilizes laser cleaning for a variety of applications, including paint removal, rust elimination, and preparing surfaces for welding or coating. The key requirements here are efficiency, speed, and the ability to clean to a precise depth without damaging the base material.

Solutions for Paint Removal and Restoration: Industrial-grade laser cleaning machines, capable of operating at higher power levels and covering larger surface areas quickly, are preferred in the automotive industry. These machines are designed for high throughput and durability, capable of withstanding the rigors of continuous operation.

Pricing: The cost of laser cleaning machines for automotive applications varies based on power, speed, and automation features. Entry-level industrial machines can start around $30,000, with more advanced, fully automated systems costing $100,000 or more. The investment reflects not only the machine’s capability to perform efficient and precise cleaning but also the long-term savings in terms of labor, consumables, and environmental impact.

7. Buying Guide: Finding the Best Value Laser Cleaning Machine

Investing in a laser cleaning machine involves a significant amount of research and negotiation to ensure you’re getting the best value for your money. This guide aims to provide you with insights on how to effectively compare prices and features of laser cleaning machines, as well as tips for negotiating with suppliers to secure the best deal.

How to Compare Prices and Features Effectively

Identify Your Needs: Clearly understand the specific cleaning applications you intend to use the machine for. Consider factors such as the types of materials you’ll be cleaning, the level of precision required, and the volume of work. This will help you narrow down the features you need, preventing overpaying for unnecessary capabilities.

Research and Shortlist: Gather information on various laser cleaning machines that meet your criteria. Look for reviews, case studies, and user testimonials to shortlist the models and suppliers with the best reputations.

Compare Technical Specifications: Focus on key specifications like laser power, wavelength, and the type of laser (fiber, CO2, etc.), as these impact the machine’s performance and suitability for your applications. Also, consider the machine’s size, ease of use, and maintenance requirements.

Evaluate Total Cost of Ownership: Look beyond the initial purchase price. Consider long-term costs such as maintenance, consumables (if any), and operational costs. A cheaper machine might be more expensive in the long run if it requires frequent repairs or has higher operating costs.

Request Demonstrations: Where possible, ask for a demonstration or samples of work done by the machine. This can give you a better idea of the machine’s capability and whether it meets your quality standards.

Top Tips for Negotiating with Suppliers

Be Informed: Enter negotiations armed with detailed knowledge about the laser cleaning machines, including market prices and the cost of similar models. This knowledge demonstrates to suppliers that you’ve done your homework, making it harder for them to overcharge.

Discuss Customization and Add-ons: If you require customization or additional features, discuss these upfront. Sometimes, suppliers are willing to offer discounts or include add-ons at a reduced price as part of the negotiation.

Ask About After-Sales Support: Good after-sales support can save you a lot of money and hassle. Negotiate for favorable terms on warranties, maintenance contracts, and support. Sometimes, securing a better warranty or free training sessions can be more valuable than a slight discount on the purchase price.

Volume Discounts: If you’re purchasing multiple units or plan to make future purchases, ask for volume discounts. Suppliers are often willing to lower the price per unit if you commit to buying more.

Payment Terms: Cash flow is crucial for any business. Negotiate payment terms that work for you, such as extended payment periods or financing options. Flexible payment terms can sometimes be more beneficial than a discount.

Compare Quotes: Always get quotes from multiple suppliers. This not only gives you leverage in negotiations but also ensures you have options if one negotiation doesn’t pan out as expected.

Don’t Rush: Finally, don’t rush your decision. Take your time to ensure you’re making the best investment for your needs. Suppliers are often more willing to negotiate if they see you’re considering other options.

Finding the best value in a laser cleaning machine requires a balance between upfront costs, operational expenses, and the benefits the machine brings to your operations. By carefully comparing options and effectively negotiating with suppliers, you can secure a machine that meets your needs at a competitive price.

8. Cost-Saving Strategies for Acquiring Laser Cleaning Technology

Investing in laser cleaning technology is a significant financial decision for many businesses. Understanding different acquisition strategies can help in making a cost-effective choice that aligns with your operational needs and budget constraints. Two viable options to consider are leasing versus purchasing and opting for refurbished machines.

Leasing vs. Purchasing: What’s More Cost-Effective?

Leasing: Leasing laser cleaning machines can be an attractive option for businesses that require the latest technology but are unable to commit to the high upfront costs of purchasing. Leasing offers the flexibility to upgrade to newer models at the end of the lease term, ensuring you always have access to the most efficient and effective technology. Additionally, lease payments are often considered operational expenses, which can provide tax benefits.

Pros:

- Lower initial investment.

- Flexibility to upgrade equipment.

- Potential tax advantages.

Cons:

- Higher long-term costs if the lease is extended.

- Limited customization options.

Purchasing: Purchasing a laser cleaning machine outright is a considerable upfront expense but offers long-term savings. Once the initial investment is recouped, the cost of ownership is typically lower compared to leasing. Purchasing allows for full customization and integration into your operations, and the machine becomes a business asset, which can be depreciated over time.

Pros:

- Lower long-term costs.

- Full control and customization of the equipment.

- Asset depreciation benefits.

Cons:

- Significant upfront capital required.

- Potential obsolescence risk as newer technologies emerge.

Deciding between leasing and purchasing should be based on your company’s financial situation, operational needs, and long-term strategy. Leasing can offer flexibility and lower initial costs, while purchasing is more cost-effective in the long run for stable operations.

Refurbished Machines: A Viable Option for Budget-Conscious Buyers

Refurbished laser cleaning machines present a cost-saving opportunity without compromising on quality. These machines are often units that have been returned from lease, used in demonstrations, or traded in and have been restored to a fully functional state by the manufacturer or a certified dealer.

Advantages:

- Significantly reduced cost compared to new models.

- Typically come with a warranty and support.

- Environmentally friendly option by reusing and recycling equipment.

Considerations:

- Limited availability of specific models or features.

- Potential shorter lifespan compared to new units.

When considering refurbished machines, it’s crucial to purchase from reputable sources that provide a warranty and after-sales support. This ensures that the machine meets your requirements and offers peace of mind regarding its reliability and performance.

8. Future Trends in Laser Cleaning Machine Pricing

The laser cleaning machine market is dynamic, with continuous technological advancements shaping pricing trends. Understanding these trends is crucial for buyers looking to invest in laser cleaning technology. This section explores how technological developments could impact machine pricing and offers insights into what buyers should know when predicting future price trends.

Technological Advancements and Their Impact on Prices

Technological advancements in laser cleaning are aimed at increasing efficiency, versatility, and safety, while also reducing operational costs. These innovations include improved laser beam quality for more precise cleaning, advancements in fiber laser technology offering higher power outputs, and the integration of AI and machine learning for smarter operation and maintenance predictions. While such advancements enhance the performance and value of laser cleaning machines, they also influence pricing in several ways:

Initial Cost vs. Operational Efficiency: New technologies often come with higher initial costs due to research and development expenses and the use of more expensive materials or components. However, these costs can be offset by the increased operational efficiency and lower maintenance costs, presenting a more favorable long-term investment for buyers.

Economies of Scale: As the adoption of advanced laser cleaning technologies grows, economies of scale can reduce production costs, potentially leading to lower prices for end-users. Increased competition among manufacturers may also drive prices down.

Customization and Specialization: Advanced technologies allow for more customization and specialization of laser cleaning machines to meet specific industry needs. While this can increase the value and effectiveness of the machines, it may also lead to higher prices for specialized equipment.

Predicting Price Trends: What Buyers Should Know

Predicting future price trends requires a careful consideration of several factors:

Market Demand: Increased demand for cleaner, more environmentally friendly cleaning solutions can drive further investment in laser cleaning technology, potentially affecting prices. High demand may keep prices stable or even increase them, whereas increased supply and competition could lead to lower prices.

Regulatory Changes: Environmental regulations and safety standards can influence the adoption of laser cleaning technology. Stricter regulations might increase demand for these eco-friendly cleaning solutions, potentially impacting prices.

Technological Convergence: The integration of laser cleaning technology with other industrial processes or technologies could lead to new applications and efficiencies, possibly affecting pricing structures as new value propositions emerge.

Global Economic Factors: Economic conditions, including trade policies and currency fluctuations, can impact the cost of components and manufacturing, thereby influencing laser cleaning machine prices.

9. Laser Cleaning Machine Vendors and Price Ranges

The market for laser cleaning machines is diverse, with a range of suppliers offering products that cater to various needs, from light, surface-level cleaning to deep, industrial-strength applications. Understanding the landscape of vendors and the price range of their offerings can help buyers make informed decisions based on their specific requirements and budget constraints. Below is an overview of the types of suppliers in the industry and the general price ranges for their laser cleaning machines.

Leading Suppliers and Their Offerings

IPG Photonics: Known for their fiber lasers, IPG Photonics offers high-power laser cleaning systems suitable for heavy-duty industrial applications. Their products are designed for efficiency and durability, targeting sectors like aerospace, automotive, and manufacturing.

W2M LASER: W2M LASER is recognized for providing a wide range of laser cleaning solutions, from compact, handheld devices to fully automated systems. They cater to conservation, automotive, and aerospace industries, emphasizing precision and safety.

Laserax: Specializing in laser cleaning for the metal industry, Laserax offers systems that remove rust, oxide, and paint from metal surfaces. Their solutions are geared towards improving manufacturing processes and product quality.

TRUMPF: A key player in the industrial laser market, TRUMPF offers laser cleaning machines that are highly customizable for various applications, including paint removal, rust cleaning, and surface preparation.

P-Laser: P-Laser focuses on eco-friendly laser cleaning solutions for rust removal, paint stripping, and historic preservation. They offer portable units for light applications and more powerful systems for industrial needs.

Price Range Overview: From Budget Solutions to Premium Models

Budget-Friendly Options: Prices for entry-level, handheld laser cleaning machines start around $10,000 to $15,000. These models are suitable for light cleaning tasks, such as removing dirt, rust, or paint from small areas. They are ideal for businesses needing a portable and easy-to-use solution for occasional cleaning applications.

Mid-Range Systems: Mid-range laser cleaning machines, which offer more power and capabilities, are priced between $20,000 and $50,000. These systems can handle more demanding tasks and are designed for more frequent use in industrial settings.

Premium Models: High-end laser cleaning systems, designed for heavy-duty industrial applications requiring high power and efficiency, can cost upwards of $50,000 to $100,000 or more. These machines often include features like automation, advanced control systems, and the ability to integrate into manufacturing lines for continuous operation.

Conclusion

The choice of a laser cleaning machine depends on the specific cleaning requirements, desired efficiency, and available budget. Leading suppliers offer a range of solutions from budget-friendly, handheld devices to premium, industrial-grade systems. By understanding the offerings and price ranges of these vendors, buyers can better navigate the market and select a laser cleaning machine that best fits their needs, ensuring a balance between performance and cost.

10. Conclusion: Maximizing Your Investment in Laser Cleaning Technology

Investing in laser cleaning technology presents an opportunity to enhance operational efficiency, reduce environmental impact, and achieve superior cleaning results across a variety of applications. However, navigating the landscape of laser cleaning machines requires careful consideration of several factors to ensure that your investment delivers the maximum return. Here’s a recap of key considerations for purchasers and insights into the future of laser cleaning technology.

Recap of Key Considerations for Purchasers

Understand Your Needs: Clearly define the cleaning applications and the level of precision required. Assess the volume of work and the types of materials you will be working with to determine the most suitable laser cleaning machine.

Consider the Total Cost of Ownership: Look beyond the initial purchase price. Factor in maintenance, operational costs, and potential savings from increased efficiency and reduced consumable use.

Evaluate Machine Features: Prioritize features based on your specific needs, including power output, portability, automation capabilities, and ease of use. Customization options can offer flexibility but may influence the price.

Research Suppliers and Products: Invest time in researching and comparing different laser cleaning machines and suppliers. Look for reviews, case studies, and seek demonstrations where possible.

Explore Financing Options: Determine whether purchasing, leasing, or considering refurbished models offers the best financial arrangement for your business’s cash flow and investment strategy.

Negotiate Value: Engage in negotiations with suppliers to explore discounts, financing deals, or added-value services like extended warranties or inclusive training sessions.

Looking Ahead: The Future of Laser Cleaning and Pricing Strategies

The laser cleaning market is evolving, driven by advancements in technology and shifting industry demands. Future trends indicate a continued focus on enhancing efficiency, reducing power consumption, and increasing the versatility of laser cleaning machines. Innovations in laser technology and integration with digital controls and artificial intelligence will likely lead to smarter, more autonomous systems that can adapt to different cleaning tasks with minimal human intervention.

As these technologies mature, we can anticipate a gradual reduction in costs due to economies of scale and increased competition among manufacturers. However, the emphasis on customization and specialized solutions for specific industries may maintain premium pricing for advanced models.

To maximize your investment in laser cleaning technology, stay informed about the latest advancements and market trends. Regularly review your operational needs and be prepared to adapt your strategy to leverage new technologies and pricing models as they emerge. This proactive approach will ensure that your business continues to benefit from the efficiency, environmental, and economic advantages offered by laser cleaning technology, well into the future.

F.A.Q.

CHIHALO LASER

The price of a laser cleaning machine is influenced by several factors including its power output, size, the technology used (fiber laser, CO2 laser, etc.), customization options, additional features like automation, and the brand. Higher power and more advanced features generally lead to a higher price.

Yes, there are entry-level laser cleaning machines designed for small businesses and less intensive applications. Prices for these models can start from around $10,000 to $15,000. These machines are typically handheld, portable, and suitable for light cleaning tasks.

Higher-priced laser cleaning machines often offer greater power, efficiency, and durability. They may also include advanced features such as automation, precise control systems, and the ability to handle a wider range of materials and contaminants. The cost reflects the technology, performance, and the potential savings in labor and materials over traditional cleaning methods.

For businesses requiring frequent use of a laser cleaning machine for heavy-duty tasks, investing in a high-end model can be worth it. These machines offer higher efficiency, faster cleaning times, and the ability to handle tougher jobs, which can improve overall productivity and quality of work.

Yes, many suppliers offer financing options to make laser cleaning machines more accessible. Leasing is also a popular option, allowing businesses to use the latest technology without a significant upfront investment. Always inquire directly with suppliers for available financing or leasing plans.

The decision between a handheld and an automated machine should be based on your specific cleaning needs, the volume of work, and your budget. Handheld machines offer flexibility and are more cost-effective for small or occasional jobs. Automated machines, while more expensive, provide efficiency and consistency for high-volume or industrial applications.

This varies by supplier. Some prices include installation, training, and initial setup, while others may charge extra. Always confirm what is included in the price before making a purchase. Comprehensive training can be crucial for maximizing the efficiency and safety of your laser cleaning operations.

Refurbished machines can be an excellent option for budget-conscious buyers. They often come at a lower cost while still providing reliable performance. Ensure you purchase refurbished equipment from a reputable supplier that includes a warranty and support.

Beyond the initial purchase price, consider maintenance costs, the potential need for replacement parts, and operational costs such as power consumption. These factors contribute to the total cost of ownership and can vary significantly between models.

Being well-informed about the market and having a clear understanding of your requirements can strengthen your negotiating position. Don’t hesitate to ask for discounts, especially if you are making a significant investment or purchasing multiple units. Also, inquire about any ongoing promotions, financing deals, or added-value services such as extended warranties or free training.