Metal Engraving and Marking by Fiber Laser Marking Machines

Fiber laser machines offer swift and efficient marking capabilities for a wide range of metals. They excel in engraving various metal surfaces, including aluminum, anodized aluminum, steel, stainless steel, magnesium, lead, and titanium.

These machines boast low maintenance requirements, require no consumables, and produce high-contrast marks. They are versatile tools for creating permanent markings such as data matrix codes, QR codes, serial numbers, barcodes, logos, and more.

Metals You Can Mark by Fiber Laser

The unique properties of each metal dictate how it absorbs light and conducts heat. Therefore, selecting the appropriate laser engraver for your application revolves around understanding the characteristics of your metal part.

Steel

Steel, known for its toughness, often requires longer marking times. But by opting for white marks over black ones, marking speed can soar. These white marks sharply contrast with steel’s natural color across various types.

For rapid marking on steel surfaces, laser etching is optimal. For durable marks, laser engraving is essential. For added corrosion resistance, laser annealing penetrates below the surface. Laser marking adapts to any steel alloy, from anodized to carbon and die steel.

Steel parts like suspension springs, brake pads, coils, billets, plates, pipes, and sheet steel benefit from precise laser marking.

Aluminum

Aluminum, with its high thermal conductivity, lends itself to rapid marking using fiber lasers even at elevated temperatures. While laser etching stands out as the swiftest method, laser engraving offers unparalleled durability.

Aluminum 380 and 6061 rank among the frequently marked alloys, but all types of aluminum are markable, including die cast, general-purpose, pure, and anodized variants.

Aluminum components such as die castings, coils, extrusions, billets, ingots, sows, and rolling slabs all benefit from precise laser marking techniques.

Stainless Steel

Laser marking is commonly employed for stainless steel grades 304 and 316, though adaptable to any grade. Laser annealing is the preferred method for stainless steel, preserving the chromium oxide layer and yielding high-quality marks while preventing surface rust.

Notably, stainless steel doesn’t necessitate a high-power laser due to the efficiency of laser annealing at lower energy levels compared to other methods.

Stainless steel components such as fuel tanks, exhausts, suspensions, and various automotive parts benefit from this precise marking technique.

WHAT DO YOU WANNA MARK?

Contact us to get the latest model and price!

Laser Marking on Metals: The Process Explained

Upon receiving your machine, it arrives pre-configured by our experts with a specific marking process tailored to the metal being marked. However, the same machine can be easily reconfigured for future applications involving different metals.

Machine configuration hinges on various laser parameters, such as laser power, movement speed, pulse duration, and number of laser passes. These configurations yield different marking processes, each with its unique advantages.

Laser Etching

Metal etching machines boast the fastest marking speed possible. This process is ideal for most applications, except when increased resistance to surface treatments, corrosion, or wear and tear is required. In such cases, engraving or annealing would be better suited.

You can laser etch: Steel, Aluminum, Anodized Aluminum, Lead, Magnesium, Zinc

Laser Engraving

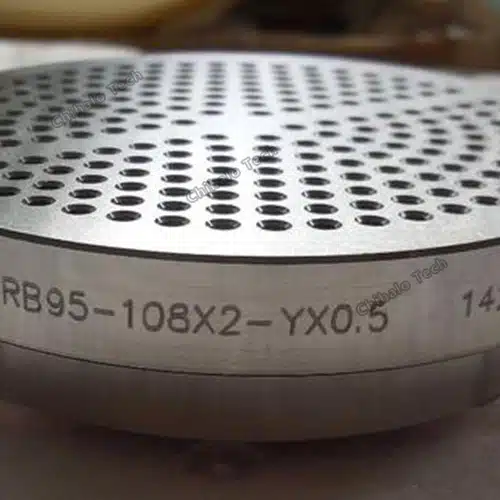

Laser engraving machines generate marks that are deep enough to resist abrasion and most surface treatments. When engraving metals with this process, you can implement traceability earlier in the production process. Examples of metal laser engraving are VIN markings and shotblast resistant markings.

You can laser etch: Steel, Aluminum, Anodized Aluminum (before anodization)

Laser Annealing

Laser annealing is used to avoid any damage to the part surface, as it is the only process that does not use laser ablation. Instead, it triggers a chemical reaction that creates marks under the material’s surface. This method is useful for parts like stainless steel exhaust lines, which must keep a high resistance to corrosion.

You can laser etch: Steel, Stainless Steel, Chrome Plating

Deep Laser Engraving

As the name suggests, deep engraving creates markings with smooth edges that are much deeper than regular engravings. This process is typically used for applications that have depth and aesthetic requirements. Some examples include logos, stamping plates, and mold inserts. The engraving speed varies based on the laser power, the material, and the line width.

You can laser etch: Steel, Stainless Steel, Aluminum

Why Use Fiber Laser Makers for Metal?

Boost Traceability

Enhance traceability capabilities through the implementation of a laser marking system. This innovative technology ensures the creation of high-precision, enduring marks, surpassing traditional methods such as inkjet printing and dot peening. Embrace a solution built on permanence and readability.

Ensure Smooth Production

Mitigate production bottlenecks through the implementation of laser marking technology. With laser powers ranging from 20W to 500W, our team meticulously optimizes parameters such as repetition rate and spot size to enhance marking speed and contrast, ensuring seamless integration into your production process.

Enhance Reliability, Minimize Upkeep

Laser technology excels in reliability, tailored for even the toughest industrial tasks. Thanks to their design lacking moving parts or consumables, fiber systems demand minimal upkeep. Additionally, fiber laser components boast exceptional durability, with a laser source boasting a mean time between failures of 100,000 hours.

Assure Complete Safety

With Chihalo laser marking machines, your workspace is fully secure from laser hazards. Crafted by experts, our machines strictly adhere to all safety standards, ensuring seamless integration into your production line without the need for extra safety measures.

Comparing Laser Marking with Other Methods

Laser marking stands as a pinnacle of modern industrial marking methods, offering unparalleled precision, efficiency, and versatility. In this article, we delve deep into the world of laser marking, comparing it with traditional marking methods to elucidate its advantages and applications.

Laser Marking vs. Mechanical Engraving

Mechanical engraving relies on physical contact between a cutting tool and the material to create marks. While effective for certain applications, mechanical engraving is limited by factors such as tool wear, depth control, and intricacy of designs. In contrast, laser marking offers unparalleled precision and flexibility, capable of producing intricate designs with micron-level accuracy without the need for physical contact.

Laser Marking vs. Chemical Etching

Chemical etching involves selectively removing material from the surface of a substrate using corrosive chemicals and masking agents. While suitable for large-scale production runs, chemical etching poses environmental and safety concerns due to the use of hazardous chemicals. Laser marking, on the other hand, is a clean and environmentally friendly process that eliminates the need for chemicals, making it ideal for applications where safety and sustainability are paramount.

Laser Marking vs. Inkjet Printing

Inkjet printing is a common method for adding marks or labels to products using ink droplets ejected from a print head. While inkjet printing offers high-speed and low-cost marking solutions, it is susceptible to fading, smudging, and wear over time. In contrast, laser marking provides permanent, high-contrast marks that are resistant to abrasion, chemicals, and environmental factors, making it ideal for applications requiring long-term durability and traceability.

Popular FAQ About Fiber Laser Marking

What factors should be considered when purchasing a fiber laser marking machine for metal marking?

Factors to consider include laser power, marking speed, marking area, software capabilities, automation features, cooling system, footprint, and budget.

What is the difference between fiber laser marking and CO2 laser marking on metal?

Fiber lasers are better suited for marking metals due to their higher absorption efficiency, whereas CO2 lasers are typically used for marking non-metallic materials like plastics, wood, and glass.

Can fiber laser marking machines be integrated into existing production lines?

Yes, fiber laser marking machines can be seamlessly integrated into existing production lines for inline marking and automation.

What are the maintenance requirements for fiber laser marking machines?

Maintenance typically includes regular cleaning of optics, checking and adjusting beam alignment, replacing consumable parts as needed, and keeping the machine clean and dust-free.

What training and support options are available for users of fiber laser marking machines?

Manufacturers typically offer training programs, user manuals, technical support, and service contracts to ensure users are properly trained and supported in operating their fiber laser marking machines.

What is the cost range of fiber laser marking machines for metal marking?

The cost of fiber laser marking machines varies depending on factors such as laser power, marking area, automation features, and brand. Prices can range from a few thousand dollars to tens of thousands of dollars.

Ready to Work Together?

Your email information will be kept strictly confidential, and our lawyers will ensure that your private information is absolutely safe!

If you need help finding the right industrial laser solution for you, we’re here to help!

Please tell us what kind of help you need, we will contact you immediately to provide you with the information you need to help you choose the most suitable solution for you!

Contact us today to start adopting better laser equipment to maximize your benefits and reduce your risks!