Professional Laser Oil Removal Systems

- Complete Guide 2025

Looking for a faster, cleaner way to remove oil from metal surfaces? Laser oil removal technology is transforming how industries handle degreasing tasks. This guide covers everything you need to know about laser cleaning systems.

Table of Contents

1. Introducing: What Is Laser Oil Removal?

Laser cleaning technology represents a significant advancement in the field of industrial cleaning. By harnessing the power of focused laser beams, this innovative method offers a non-contact, environmentally friendly solution for removing oil and cleaning various surfaces.

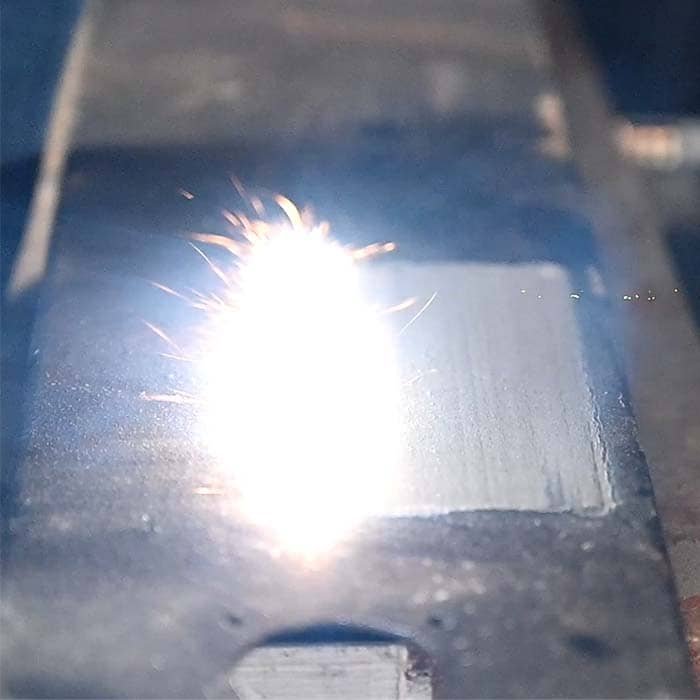

Laser oil removal uses focused light beams to vaporize oil and grease from surfaces. The process works by heating oil molecules until they break apart and evaporate. Unlike chemical cleaners or sandblasting, lasers don’t touch the surface or leave residue.

The technology targets oil layers specifically. Metal substrates remain untouched because they have different absorption properties. This selective cleaning prevents damage to expensive parts.

2. How Laser Oil Cleaning Works?

The process happens in seconds. A fiber laser emits infrared light at 1064nm wavelength. Oil absorbs this energy and heats rapidly to 300-500°C. The sudden temperature spike creates explosive vaporization at the oil-metal interface.

At its core, laser cleaning works by directing a high-energy laser beam onto the surface to be cleaned. The energy from the laser effectively vaporizes contaminants such as oil and grease, leaving behind a clean surface without the need for harsh chemicals or abrasive materials.

Key steps:

- Laser beam hits oil-contaminated surface

- Oil absorbs light energy and heats instantly

- Molecular bonds break, turning oil into vapor

- Fume extraction removes vaporized particles

- Clean metal surface remains undamaged

Pulsed lasers deliver energy in nanosecond bursts. This prevents heat buildup in the substrate. Continuous wave lasers work faster but generate more heat.

3. The Irreplaceability of Laser Cleaning and Degreasing

The irreplaceability of laser cleaning and degreasing lies in its precision, efficiency, and versatility. Unlike traditional methods such as chemical cleaning or abrasive blasting, laser cleaning offers a non-contact, non-abrasive solution that eliminates the risk of surface damage. Its pinpoint accuracy allows for selective cleaning, targeting only the contaminants without affecting the substrate material.

Furthermore, laser cleaning is highly efficient, capable of removing rust, paint, grease, and other contaminants in a fraction of the time compared to conventional methods. This efficiency translates to increased productivity and cost savings for industries where cleanliness is paramount, such as automotive manufacturing, aerospace, and electronics.

Moreover, laser cleaning is a versatile solution that can be tailored to various applications and materials. Whether it’s removing oxides from metal surfaces, restoring delicate artifacts, or preparing surfaces for bonding, laser cleaning offers unmatched flexibility.

4. Laser Power Requirements

Oil removal needs specific power levels:

- 100-200W: Light machine oils, precision parts

- 300-500W: Standard industrial lubricants

- 1000W+: Heavy grease, burnt-on deposits

- 2000W+: Production line speeds, thick contamination

Higher power means faster cleaning. A 500W laser cleans 12 square meters per hour removing standard oils. Lower power provides more precision for delicate components.

5. Types of Oil Effectively Removed

Modern laser systems handle various contamination types:

Light oils: Cutting fluids, hydraulic oils, machine lubricants Heavy oils: Gear oils, bearing grease, industrial lubricants

Burnt deposits: Carbonized oils, heat-damaged lubricants Mixed contamination: Oil plus dirt, rust, or paint layers

Mineral oils vaporize easier than synthetic alternatives. Thick oil films up to 150 microns clean completely in single passes.

6. Industries Using Laser Oil Removal

Laser oil removal technology has revolutionized industrial cleaning across various sectors, offering precise, efficient, and environmentally friendly solutions for removing oil, grease, and contaminants from surfaces. Let’s explore some of the key applications of laser oil removal.

Engine Block Cleaning:

- Situation: A car manufacturing plant needed to clean oil residues from engine blocks before assembly.

- Application Details: Laser oil removal was used to precisely clean oil passages and surfaces of engine blocks without damaging sensitive components.

- Customer Evaluation: “The laser cleaner drastically improved our production efficiency by eliminating the need for manual cleaning methods. It ensured pristine engine surfaces, leading to smoother assembly and higher-quality engines.”

Aircraft Maintenance:

- Situation: An aircraft maintenance facility required a method to remove oil deposits from aircraft engine components.

- Application Details: Laser oil removal was employed to effectively clean oil-contaminated surfaces of turbine blades and engine housings, ensuring optimal performance and safety.

- Customer Evaluation: “The laser cleaner provided unparalleled precision in removing oil residues from critical engine components. It helped us maintain strict aviation standards and improve engine reliability.”

Hydraulic Equipment Cleaning:

- Situation: A hydraulic equipment manufacturer needed to remove oil residues from hydraulic cylinders and valves.

- Application Details: Laser oil removal was utilized to clean internal and external surfaces of hydraulic components, ensuring smooth operation and longevity.

- Customer Evaluation: “The laser cleaner exceeded our expectations in removing oil contaminants from intricate hydraulic parts. It improved equipment performance and reduced maintenance costs significantly.”

Ship Engine Overhaul:

- Situation: A shipyard was tasked with cleaning oil deposits from ship engine components during routine maintenance.

- Application Details: Laser oil removal was employed to clean crankshafts, pistons, and valves of marine engines, enhancing efficiency and reducing emissions.

- Customer Evaluation: “The laser cleaner revolutionized our ship engine maintenance process. It allowed for thorough oil removal in tight spaces, leading to improved engine performance and reduced environmental impact.”

Equipment Maintenance:

- Situation: A mining company required a method to remove oil residues from heavy equipment components in harsh mining environments.

- Application Details: Laser oil removal was utilized to clean oil-soaked surfaces of excavator buckets, hydraulic pumps, and drill rigs, improving equipment reliability and longevity.

- Customer Evaluation: “The laser cleaner proved invaluable in removing stubborn oil residues from our mining equipment. It helped minimize downtime and maintenance costs, leading to increased productivity.”

Reactor Cleaning:

- Situation: A chemical plant needed to remove oil and chemical residues from reactor vessels and process equipment.

- Application Details: Laser oil removal was used to clean reactor surfaces, ensuring product purity and safety in chemical processing operations.

- Customer Evaluation: “The laser cleaner provided a precise and efficient solution for removing oil contaminants from our reactor vessels. It improved product quality and reduced the risk of contamination.”

Wind Turbine Maintenance:

- Situation: A wind farm operator sought a method to clean oil residues from wind turbine components.

- Application Details: Laser oil removal was employed to clean gearbox housings and bearings of wind turbines, enhancing reliability and performance.

- Customer Evaluation: “The laser cleaner played a crucial role in maintaining our wind turbines. It ensured thorough oil removal, reducing friction and extending the lifespan of critical components.”

Locomotive Engine Cleaning:

- Situation: A railway depot needed to clean oil residues from locomotive engines to improve performance and reliability.

- Application Details: Laser oil removal was utilized to clean engine surfaces, including fuel injectors and exhaust systems, ensuring optimal operation and emissions compliance.

- Customer Evaluation: “The laser cleaner provided an efficient and environmentally friendly solution for cleaning our locomotive engines. It helped us meet strict emissions standards and reduce fuel consumption.”

Gas Turbine Maintenance:

- Situation: A power plant required a method to remove oil deposits from gas turbine components.

- Application Details: Laser oil removal was employed to clean turbine blades and casings, improving efficiency and reducing maintenance downtime.

- Customer Evaluation: “The laser cleaner proved indispensable in maintaining our gas turbines. It removed oil residues with precision, leading to improved turbine performance and lower operating costs.”

Equipment Cleaning:

- Situation: A food processing plant needed to remove oil residues from equipment surfaces to ensure food safety and hygiene.

- Application Details: Laser oil removal was used to clean conveyor belts, mixers, and packaging machines, ensuring compliance with food safety standards.

- Customer Evaluation: “The laser cleaner provided a hygienic and efficient solution for removing oil contaminants from our food processing equipment. It helped us maintain high-quality standards and meet regulatory requirements.”

7. Safety Requirements

Laser oil removal needs proper safety measures:

Eye Protection

Class 4 lasers require wavelength-specific safety glasses. Never look directly at laser beams or reflections.

Fume Extraction

Oil vaporization creates fumes containing organic compounds. Ventilation systems must capture particles at source. HEPA filtration removes 99.97% of contaminants.

Operator Training

Basic certification takes 4-8 hours. Training covers laser safety, equipment operation, and maintenance procedures.

Work Area Control

Establish laser hazard zones with appropriate signage. Block access when systems operate.

8. Cost Analysis vs Traditional Methods

Initial Investment:

Laser systems cost $30,000-$200,000 depending on power and features. Chemical cleaning setups cost $5,000-$15,000.

Operating Costs:

Lasers cost under $1 per hour to operate. No consumables needed except electricity. Chemical systems require constant solvent purchases, disposal fees, and PPE replacement.

Labor Savings:

Laser cleaning reduces prep time by 60-80%. No surface preparation or post-cleaning required. One operator handles tasks that previously needed three people.

ROI Timeline:

Most businesses recover laser system costs within 12-18 months through labor savings and eliminated consumable costs.

9. Equipment Selection Guide

Handheld Systems:

Best for maintenance, repair work, and small batches. Weight ranges from 15-40 pounds. Power typically 100-500W.

Stationary Systems:

Ideal for production lines and large components. Include robotic integration options. Power ranges 500-3000W.

Enclosed Cabinets:

Provide maximum safety for small parts cleaning. Include fume extraction and viewing windows. Perfect for precision work.

Water vs Air cooling:

Air-cooled systems are portable but limited to 500W. Water-cooled systems handle higher powers but need plumbing connections.

10. Maintenance Requirements

Fiber lasers last 100,000+ hours with proper maintenance. No major overhauls needed for 10+ years.

Laser cleaning systems need minimal upkeep:

Weekly Tasks:

Clean protective lenses, check fume extraction filters, inspect cables for damage.

Monthly Tasks:

Replace cooling filters, calibrate power settings, clean scanner mirrors.

Annual Service:

Professional inspection, laser source alignment, safety system testing.

11. Common Mistakes to Avoid

Wrong Power Selection:

Using excessive power damages substrates. Too little power leaves residue. Match power to contamination type. Start with lower settings and increase gradually until achieving desired results.

Inadequate Ventilation:

Poor fume extraction creates health hazards and reduces cleaning quality. Size extraction systems properly. Calculate airflow requirements based on laser power and work area size. Most systems need 1000-2000 CFM extraction capacity.

Skipping Training:

Untrained operators cause equipment damage and safety incidents. Invest in proper certification. Budget $2000-5000 for comprehensive training programs. Include safety protocols, maintenance procedures, and troubleshooting techniques.

Ignoring Surface Preparation:

Heavy rust or paint layers block laser access to oil. Pre-clean if necessary. Remove loose debris manually before laser treatment. Thick coatings may require multi-pass cleaning strategies.

Poor Focal Distance Control:

Maintaining correct standoff distance is critical. Most handheld systems work best at 8-12 inches from surface. Too close causes lens damage. Too far reduces cleaning effectiveness.

12. Why Use Laser Technology for Oil Removal?

Laser cleaning is a cutting-edge technology that offers numerous advantages over traditional cleaning methods

Ensure Workplace Safety

When lasers are integrated with a dust extraction system and a Class-1 laser safety enclosure in manufacturing environments, they are extremely safe. With these precautions, operators near the laser system no longer require personal protective equipment for respiratory, hearing, or body protection. Additionally, they no longer handle hazardous materials.

Eliminate Consumables & Embrace Sustainability

Laser cleaning, a green technology, supplants rust removal methods reliant on consumables or chemicals. It's the sole solution aligning with environmental regulations. Moreover, pulsed fiber lasers boast minimal power consumption. Though laser cleaning produces slight airborne dust, our provided dust extraction system swiftly vacuums it, preconfigured as per your requirements.

Reduce Maintenance Burden

Abrasive blasting users encounter frequent interruptions due to sand presence, nozzle condition, or replacement needs, requiring regular monitoring and maintenance. Laser rust removal, a non-contact method, continually removes rust, significantly reducing maintenance costs.

Automate Workforce Tasks

Manual cleaning of each part is inefficient and costly. Opt for robotic efficiency with laser cleaning, easily fully or semi-automated. Choose a standard turnkey solution or collaborate with us and your system integrator for a tailored plant solution.

Request Sample Cleaning!

Do you wanna know the most suitable laser cleaner for your applications?

13. Comparing Laser Rust Removal with Other Methods

When it comes to rust removal, there are several methods available, each with its own set of pros and cons. While traditional methods like chemical treatments and mechanical scrubbing have been around for years, laser rust removal is a relatively new but rapidly growing technology. In this section, we’ll compare laser rust removal with other prevalent methods to help you make an informed decision for your specific needs.

Laser Oil Removal

- Principle: Utilizes laser technology to irradiate the oil-contaminated surface, causing the oil to evaporate or ablate without damaging the underlying metal.

- Pros:

- Precise and selective removal of oil without damaging the metal surface.

- Non-contact process, reducing the risk of surface damage.

- Can be automated for high efficiency and accuracy.

- Cons:

- Initial equipment cost can be high.

- Limited effectiveness on heavy or thick oil deposits.

- Safety considerations due to laser operation.

Solvent Cleaning

- Principle: Uses chemical solvents to dissolve and remove oil from the metal surface.

- Pros:

- Effective for removing a wide range of oil types and thicknesses.

- Relatively low cost compared to some other methods.

- Can be applied manually or through automated systems.

- Cons:

- Environmental and health concerns related to solvent use.

- Potential for residue or contamination if not rinsed properly.

- Some solvents may be flammable or volatile.

Mechanical Methods

- Principle: Involves physically scrubbing or abrading the oil from the metal surface using tools like brushes, abrasives, or blasting media.

- Pros:

- Versatile and can be applied to various shapes and sizes of metal surfaces.

- Can be effective for removing heavy or stubborn oil deposits.

- No chemical residues left behind.

- Cons:

- Risk of surface damage, especially for softer metals.

- Labor-intensive and time-consuming, especially for large areas.

- May generate airborne contaminants if using abrasive blasting methods.

Ultrasonic Cleaning

- Principle: Utilizes ultrasonic waves in a cleaning solution to create microscopic bubbles that agitate and dislodge oil from the metal surface.

- Pros:

- Effective for removing oil from complex geometries and internal surfaces.

- Non-contact process, reducing the risk of surface damage.

- Can penetrate small crevices and pores.

- Cons:

- Limited effectiveness on heavy or thick oil deposits.

- Requires a suitable cleaning solution and adequate rinsing.

- Equipment costs can be significant.

Steam Cleaning

- Principle: Uses high-pressure steam to dislodge and remove oil from the metal surface, often with the aid of detergents or degreasers.

- Pros:

- Environmentally friendly, as it typically requires only water and minimal chemicals.

- Effective for removing oil from intricate or hard-to-reach areas.

- Can be relatively quick and efficient.

- Cons:

- Risk of thermal shock or damage to sensitive materials.

- Limited effectiveness on heavy or thick oil deposits.

- May require specialized equipment for high-pressure steam generation.

Electrocleaning

- Principle: Passes an electrical current through the metal immersed in a cleaning solution, helping to break down and remove oil contaminants.

- Pros:

- Can be effective for removing oil from conductive metal surfaces.

- Can be combined with other cleaning methods for enhanced effectiveness.

- Can be automated for consistent results.

- Cons:

- Limited effectiveness on non-conductive or non-metallic surfaces.

- Requires careful control of electrical parameters to prevent damage.

- Potential for electrolysis-related surface damage if not properly controlled.

Take a peek inside our Wonderworld

14. Chihalo Laser Cleaning Systems

No matter what material you wanna clean, no matter what machines you are looking for, you can alwayls find a suitable solution here!

15. Getting Started

Assessment Phase:

Evaluate current cleaning processes, costs, and volumes. Document oil types and substrate materials.

Testing Services:

Most suppliers offer sample cleaning demonstrations. Ship test parts for evaluation before purchasing.

Installation Planning:

Consider electrical requirements, ventilation needs, and operator workspace. Allow 2-4 weeks for setup.

Training Schedule:

Plan operator certification before equipment arrival. Budget 1-2 days per person for comprehensive training.

16. Popular FAQ About Laser Cleaning

What types of surfaces can be cleaned using laser cleaning machines?

Laser cleaning machines can be used on a wide range of surfaces, including metals, plastics, ceramics, composites, and more. They are versatile and effective for removing oil, grease, rust, paint, coatings, and other contaminants.

What are the main components of a laser cleaning machine?

A typical laser cleaning machine consists of a laser source, beam delivery system, focusing optics, scanning head, control unit, and safety features such as fume extraction and laser safety enclosures.

What factors should be considered when purchasing a laser cleaning machine?

Factors to consider include laser power, wavelength, beam delivery options, scanning capabilities, automation features, safety features, maintenance requirements, and customer support.

Are laser cleaning machines easy to operate and maintain?

Yes, laser cleaning machines are relatively easy to operate and maintain. They require periodic maintenance such as lens cleaning, alignment checks, and laser source calibration.

What safety precautions should be taken when operating a laser cleaning machine?

Safety precautions include wearing appropriate laser safety eyewear, ensuring proper ventilation in the workspace, implementing safety interlocks, and following manufacturer’s safety guidelines.

How long does it take to clean a surface using a laser cleaning machine?

The cleaning time depends on factors such as the size of the surface, the type and thickness of the contamination, and the laser parameters. Generally, laser cleaning is faster than traditional cleaning methods.

Does laser cleaning damage substrates?

No, when properly configured, laser cleaning does not damage substrates. The technology exploits the difference in ablation thresholds between oil (lower threshold) and metal (higher threshold). Oil vaporizes at energy levels that leave metal surfaces untouched.

How much does a laser oil removal machine cost?

Laser cleaning systems range from $3,000 for basic 20W handheld units to $200,000+ for high-power automated systems. Price factors include:

- Power level (100W-3000W)

- Cooling system (air vs water)

- Automation features

- Safety enclosures

- Custom configurations

What's the relationship between laser power and oil removal speed?

Higher power enables faster cleaning and handles thicker contamination:

- 100-200W: Light machine oils, precision work

- 300-500W: Standard industrial lubricants

- 1000W+: Heavy grease, burnt deposits

- 2000W+: Production line speeds, thick films

Do I need secondary cleaning after laser treatment?

Generally no. Most oils vaporize completely, leaving clean surfaces ready for subsequent processes like welding, painting, or coating. Some applications may benefit from compressed air to remove loose particles.

What maintenance do laser cleaning systems require?

Minimal maintenance compared to traditional cleaning equipment:

- Weekly: Clean protective lenses, check filters

- Monthly: Replace cooling filters, calibrate settings

- Annual: Professional inspection, alignment check

- Consumables: Minimal – mainly replacement lenses and filters

What training is required to operate laser cleaning equipment?

Basic certification takes 4-8 hours covering:

- Laser safety protocols

- Equipment operation procedures

- Parameter adjustment techniques

- Maintenance requirements

- Emergency procedures

What after-sales service and technical support is available?

Comprehensive support typically includes:

- Training programs: Operator certification

- Remote monitoring: Real-time system diagnostics

- Technical hotline: Expert troubleshooting

- Preventive maintenance: Scheduled service visits

- Software updates: Latest cleaning parameters

How can I schedule a free trial or technical demonstration?

Most suppliers offer sample testing services:

- Send test parts: Mail samples for evaluation

- On-site demos: Equipment demonstration at your facility

- Video consultations: Remote technical discussions

- ROI calculations: Custom cost-benefit analysis

Can laser cleaning systems be customized for specific applications?

Yes, many systems offer customization options:

- Power levels: Matched to contamination type

- Beam delivery: Handheld, robotic, or fixed mounting

- Safety features: Enclosures, interlocks, sensors

- Integration: Connection to existing production lines

- Software: Custom cleaning programs and parameters

Can laser systems handle mixed contamination (oil plus rust or paint)?

Yes, laser systems excel at removing multiple contamination layers. Strategy involves:

- High power initial pass: Remove bulk contamination

- Lower power finishing: Achieve precision cleaning

- Parameter adjustment: Optimize for each contamination type

- Multi-pass technique: Ensure complete removal without damage