Customized High-quality Laser

Industrial Laser Cleaning Machines - Professional for Industrial Applications

Transform Your Industrial Cleaning with Advanced Laser Technology

Chihalo’s Industrial laser cleaning machines deliver precision rust removal, paint stripping, and surface preparation without chemicals or abrasives. Since 2016, we’ve helped 1000+ companies across automotive, aerospace, and manufacturing industries achieve faster, safer, and more cost-effective cleaning solutions.

Featured Laser Cleaners

Industrial Laser Cleaning Machine Product Line

Whether you’re dealing with rust or paint removal, working with metal, wood, or stone, or need a solution for individual hand-held tasks or large-scale automated projects, you’ll find the perfect one-stop laser cleaning solution.

Pulse Laser Cleaning Machines

(1KW - 3KW)

Air-Cooled CW Laser Cleaner

(800W - 2000W)

Industries We Serve

Industrial Laser Cleaning Applications

Ready to Get Started?

Fill out the form below to request a quote or learn more about our customizable laser cleaning solutions. Let’s tailor the perfect system for your needs!

Comparasion

Why Choose Laser Cleaning Over Traditional Methods?

| Factor | Traditional Methods | Chihalo Laser Cleaning |

|---|---|---|

| Environmental Impact | ❌ Chemical waste, toxic fumes, hazardous disposal | ✅ Zero emissions, eco-friendly process |

| Surface Protection | ❌ Risk of damage, surface abrasion, material loss | ✅ Non-contact precision, substrate preservation |

| Operating Costs | ❌ High consumable costs, frequent replacement needed | ✅ Low maintenance, no consumables required |

| Worker Safety | ❌ Health hazards, extensive PPE requirements | ✅ Operator safe, minimal protective equipment |

| Precision Control | ❌ Limited selectivity, over-processing common | ✅ Micrometer precision, selective removal |

| Automation Ready | ❌ Manual labor intensive, hard to automate | ✅ Fully automated compatible, robotic integration |

Simple 4-Step Process

How Laser Cleaning Technology Works?

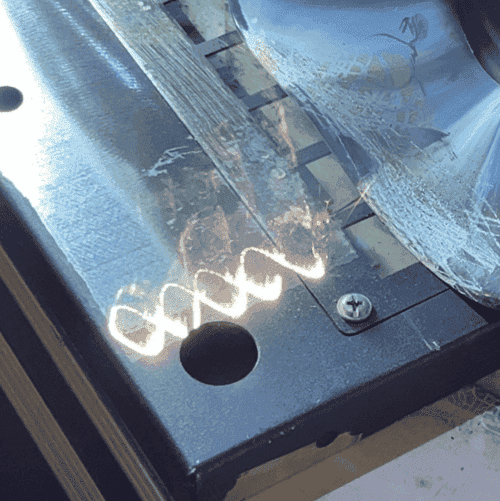

Step 1: Laser Beam Generation High-intensity fiber laser generates focused beam at optimal wavelength (1064nm) for maximum contaminant absorption while protecting base materials.

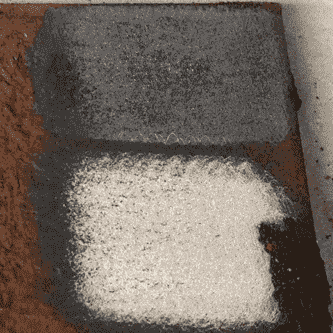

Step 2: Selective Absorption

Laser energy is absorbed by rust, paint, or contaminants while the base material remains unaffected due to different absorption characteristics – this selectivity is key to safe cleaning.

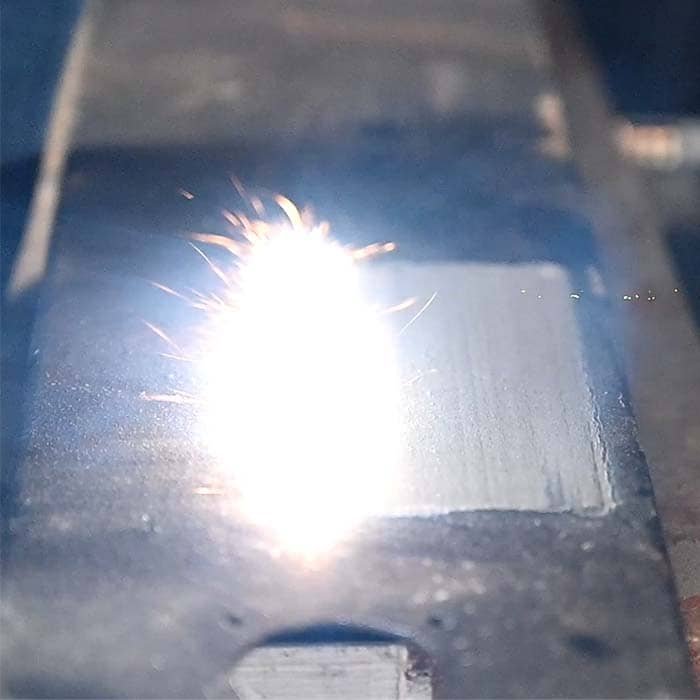

Step 3: Instant Vaporization Absorbed energy instantly vaporizes contaminants into gas or fine particles through controlled thermal ablation, leaving the clean surface completely intact.

Step 4: Clean Results Integrated air jet system removes vaporized particles and debris, revealing pristine surface ready for coating, welding, or further processing.

Laser Cleaning Technical Advantages:

- Precise Power Control: 1-100% power adjustment for any material

- Multiple Pulse Modes: Continuous wave and pulsed options available

- Real-time Monitoring: Process feedback and quality control systems

- Customizable Parameters: Frequency, power, speed optimization for your application

WORK TOGETHER

What People Are Saying?

Thomas

It really helped me out. Starting a cleaning service is tough, but this laser cleaner helped me make money faster.

We rent laser cleaners in the US and have bought over 80 units of CHIHALO machines in the past 3 years. We are pleasantly surprised by the quality and service of the Chinese factory.

Matthew

Fernando

Chihalo ofrece diseños gratis para ayudarnos a crear nuestra propia marca de láser, y nos proporciona muchas oportunidades de venta en Sudamérica. Son buenos amigos para siempre.

About Chihalo Service

2 Years of warranty for the whole machine; Lifetime free after-sales service.

OEM MOQ 1 Unit. Free automatic solution in one-stop.

If the machine doesn’t meet the standards we advertised or that we agreed to in our contract, you can return it at no cost to you.

Gain expert knowledge with our comprehensive online courses, designed to help you master the operation and maintenance of your laser cleaning equipment.

Keep your laser cleaning machines performing at their best with our lifetime maintenance and upgrade services, ensuring longevity and cutting-edge functionality.

Keep your laser cleaning machines running at peak performance with our lifetime maintenance and upgrade services, ensuring longevity and state-of-the-art functionality.

How to order

We Are There Every Step!

1 Inquiry and Consultation

Tell us what you need. We’ll talk to you about it and help you figure out which laser cleaner is the best fit for you.

2 Quotation and Customization

Get a quote. If you need something special, we’ll make it for you. We can do OEM or automated stuff if you need it.

3 Order and Production

Place your order, and we’ll start making your laser cleaner. We’ll make sure it’s customized to your specs and meets our quality standards.

4 Delivery and After-Sales

Once your machine is done, we’ll ship it to you safely and quickly. Our customer support team will help you set it up, train you, and keep it running.

About Laser Cleaning Machines

FAQ

What is the cost of an industrial laser cleaning machine?

Which industries benefit most from laser cleaning equipment?

Is industrial laser cleaning really better than sandblasting or chemicals?

How safe are industrial laser cleaning machines for operators?

What maintenance do an industrial laser cleaning machines require?

Can I see this industrial laser cleaning machine demonstration?

Get Your Custom Laser Cleaning Solution Today

Ready to Transform Your Cleaning Process?

Join 1000+ satisfied customers who chose Chihalo industrial laser cleaning machines for superior results. Get personalized consultation from our laser technology experts and discover the perfect solution for your specific application.

✓ Free consultation with experienced laser engineers

✓ Custom solution design tailored to your exact needs

✓ Live demonstration using your actual materials

✓ Factory-direct pricing with no middleman markup

✓ Fast delivery and comprehensive installation support

✓ Lifetime technical support from our engineering team