Pulse High Power Laser Cleaning Machine

- 5mJ / 13mJ / 50mJ / 100mJ For Option

- Build-in Chiller, Portable and Compact Design

- High Efficiency & Precision & Non-damage

What is MOPA Multi-mode Pulse High Power Laser Cleaning Machines?

Multimode laser cleaners are named for the type of laser they use.

From its outlooking, the machine is lightweight with a water-cooled structure and the cleaning head can be handheld.

From the cleaning effect, the surface is more even and non-destructive, can restore the original color of the metal, and is suitable for sensitive materials.

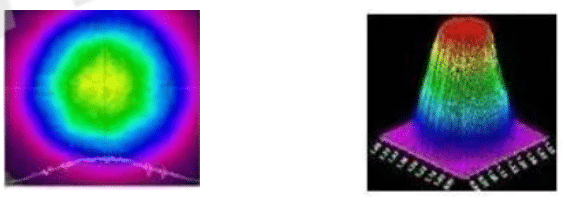

From its principle, the multi-mode laser is a kind of flat-top light, the spot energy is evenly distributed, so that the cleaning effect of each action area is consistent, so it is more uniform. Usually, it has a larger spot, which also makes the energy dispersion, and efficiency accelerated at the same time will not damage the surface of the substrate.

Exclusive Advantages

Usually, its power range is higher, and the highest commonly used power is the pulse 2KW laser cleaning machine.

At the same time, its pulse energy is also higher, currently up to 100mJ.

-

High Pulse Laser Power Pulse powers from 200W to 2000W are available. MOPA amplification technology allows peak power to exceed 20KW.

-

High Single Point Energy The higher the energy, the better the cleaning ability. 5mJ/ 13mJ/ 50mJ/ 100mJ for option.

-

Less Damage on Base Flat-top light design, even energy distribution, more non-destructive and uniform cleaning effect. Larger light spot, larger single coverage area, higher efficiency.

-

Compact Water-cooled Design Water cooling provides better protection for the laser and cleaning motors and extends the life of long working hours.

-

Portable Cleaning Handle 2KG handheld cleaning head for long time use. Triple safety protection switch prevents accidental laser out.

-

20m Long Fiber Cable The extra-long fiber optic cable allows you to use the machine wherever you want, without having to think about moving and cramped space.

Parameters

| Model | CF-200L | CF-300L | CF-500L | CF-500LP | CF-1000L | CF-1000LP |

|---|---|---|---|---|---|---|

| Wavelength | 1064nm | 1064nm | 1064nm | 1064nm | 1064nm | 1064nm |

| Laser Power | 200W | 300W | 500W | 500W | 1000W | 1000W |

| Pulse Energy | 13mJ | 13mJ | 13mJ | 50mJ | 50mJ | 100mJ |

| Beam Size | 4-6mm | 4-6mm | 4-6mm | 4-6mm | 4-6mm | 4-6mm |

| Fiber Cable | 5m/10m | 5m/10m | 5m/10m | 10m | 10m | 10m |

| Pulse Width | 50~500ns | 50~500ns | 50~500ns | 50~500ns | 50~500ns | 50~500ns |

| Frequency | 16~3000kHz | 25~3000kHz | 40~3000kHz | 500~3000kHz | 500~3000kHz | 500~3000kHz |

| Work-area | 200mm*20mm | 200mm*20mm | 200mm*20mm | 300mm*20mm | 300mm*20mm | 300mm*20mm |

| Scan Graphics | Spiral and so on | Spiral and so on | Spiral and so on | Spiral and so on | Spiral and so on | Spiral and so on |

| Cooling | Water Cooling | Water Cooling | Water Cooling | Water Cooling | Water Cooling | Water Cooling |

| Work Temperature | 0-40℃ | 0-40℃ | 0-40℃ | 0-40℃ | 0-40℃ | 0-40℃ |

| Optical Weight | 1.5KG | 1.5KG | 1.5KG | 2.5KG | 2.5KG | 2.5KG |

| Machine Weight | 160KG | 160KG | 160KG | 160KG | 160KG | 160KG |

| Machine Size | 115cm*70cm*110cm | 115cm*70cm*110cm | 115cm*70cm*110cm | 115cm*70cm*110cm | 115cm*70cm*110cm | 115cm*70cm*110cm |

| Input Power | 220V 50-60Hz | 220V 50-60Hz | 220V 50-60Hz | 220V 50-60Hz | 220V 50-60Hz | 220V 50-60Hz |

| Power Consumption | 600W | 1500W | 2000W | 4500W | 4500W | 4500W |

Benefit of Pulse High Power Laser Cleaning Machine

- Portability

Military harness supplier, ergonomic design, suitable for long-term use. - High cleaning efficiency

Customized small-sized high-energy laser, equipped with a dual motor cleaning system, can quickly remove stains, rust, oil stains, etc. - Easy to Operate

Ready to use upon startup, no preparation or waiting required. User Friendly interface, no need for complex training. - Multifunctionality

All parameters are adjustable and suitable for cleaning various materials and surfaces, including metal, wood, stone, etc. - Security

Equipped with safety protection measures to ensure personal safety during use. - Durability

The device is designed to be waterproof and dustproof, with a sturdy structure, wear-resistant and durable, suitable for long-term use.

Options for Pulse High Power Laser Cleaning Machine

1 Laser Configuration

Power range is from 20W to 300W. Higher power increases the cleaning efficiency, reducing working time.

2 Air Knife

Installed on the cleaning head to prevent dust from accumulating on the lens by blowing out a continuous stream of clean air. This not only extends lens life, but also speeds up cleaning efficiency.

3 Dust & Fume Extraction

Vacuum devices of various sizes and specifications can be optionally integrated into the cleaning head and are equally portable.

4 Fixed Focus Frame

In 2D cleaning, the focus can be maintained and the cleaning effect is more uniform.

Typical Applications of Pulse High Power Laser Cleaning Machine

1 Graffiti Removal

Power range is from 20W to 300W. Higher power increases the cleaning efficiency, reducing working time.

2 Rust Removal in Remote Locations

These machines can be easily carried to remote or hard-to-reach locations like pipelines, bridges, or offshore platforms for rust removal and surface preparation.

3 Cultural Relic Restoration

The backpack design allows conservators to carefully clean and restore artifacts and historical monuments on-site, without the need for transporting sensitive items.

4 High-Altitude Cleaning Tasks

The lightweight and portable nature of these machines make them suitable for high-altitude tasks like cleaning communication towers, wind turbines, or mountain installations.

Typical Applications

Laser rust removal, laser paint removal, furniture cleaning, kitchenware cleaning, automotive parts maintenance, and more

Mold Laser Cleaning

Laser Paint Removal

Stone/Artifact Cleaning

Frequently Asked Questions.

Yes, the equipment supports integrated automation systems that can enhance productivity.

We provide long-term maintenance service and technical support to ensure the stable operation of the equipment.

It is suitable for metal, plastic, glass, ceramic, stone and other materials.

The maintenance cost of the equipment is low, only need regular inspection and cleaning, the running cost is relatively low.

Under normal maintenance and care, the service life of the equipment can be more than ten years.

Generally, the lead time for standard equipment is 4-6 weeks, depending on the order.

Related Blogs

Does Laser Cleaning Damage Metal?

....This non-contact, non-abrasive process ensures the integrity of the underlying material is preserved....

Does Laser Cleaning Really Work?

Laser cleaning is a cleaning technology that utilizes a high-energy laser beam to irradiate the surface of an object, thereby removing contaminants, oxidized layers, paints and other impurities.

What Do Laser Cleaners Cost?

Although laser cleaners are expensive, their high efficiency, environmental friendliness, and precision cleaning capabilities provide significant value to the user.