1 Introduction to Laser Paint Removal for Wood

Laser paint removal for wood is gaining traction as a safe and effective method for cleaning wooden surfaces. Let’s explore how this innovative technology works and its unique advantages.

1.1 Overview of Laser Technology in Paint Removal

How Laser Paint Removal Works:

- The laser uses focused beams of light energy to break down paint particles on the wooden surface.

- These particles vaporize or are lifted off the surface, leaving the underlying wood clean and intact.

Types of Lasers Used:

- Fiber Lasers: Common for their high efficiency and precise control over heat output.

- CO2 Lasers: Often used for broader applications, they deliver consistent results across different types of coatings.

Surface Compatibility:

- Lasers can be adjusted to varying power levels and pulse durations to accommodate different wood types and coating thicknesses.

- This flexibility ensures effective removal without damaging the wood surface.

1.2 Benefits of Choosing Laser Paint Removal for Wood

Precision Cleaning:

- Lasers can be precisely controlled to remove specific layers or coatings without affecting the underlying wood, ideal for detailed restoration projects.

Eco-Friendly Process:

- Unlike traditional chemical stripping methods, lasers produce no hazardous waste and require no additional consumables.

- The process is virtually dust-free and leaves minimal residues.

Reduced Labor and Faster Processing:

- Lasers minimize the need for manual scrubbing and reduce preparation time.

- This efficiency translates to quicker project completion.

Versatility in Application:

- Suitable for stripping paint, varnish, or other finishes from furniture, beams, and decorative woodwork.

- Works well on intricate carvings, grooves, or other hard-to-reach areas.

Lower Long-term Costs:

- Despite a higher initial investment, the durability and speed of laser cleaning can result in significant cost savings over time.

In summary, laser paint removal provides a powerful solution for cleaning wood surfaces with unparalleled precision and environmental consideration, making it a superior choice for restoration and maintenance projects.

2 Understanding Laser Paint Removal Technology

Laser paint removal for wood is a modern cleaning technique that uses high-intensity laser beams to strip unwanted coatings from surfaces. Let’s delve into how this technology functions and the different types of lasers utilized.

2.1 How Laser Paint Removal Works

Laser Beam Emission:

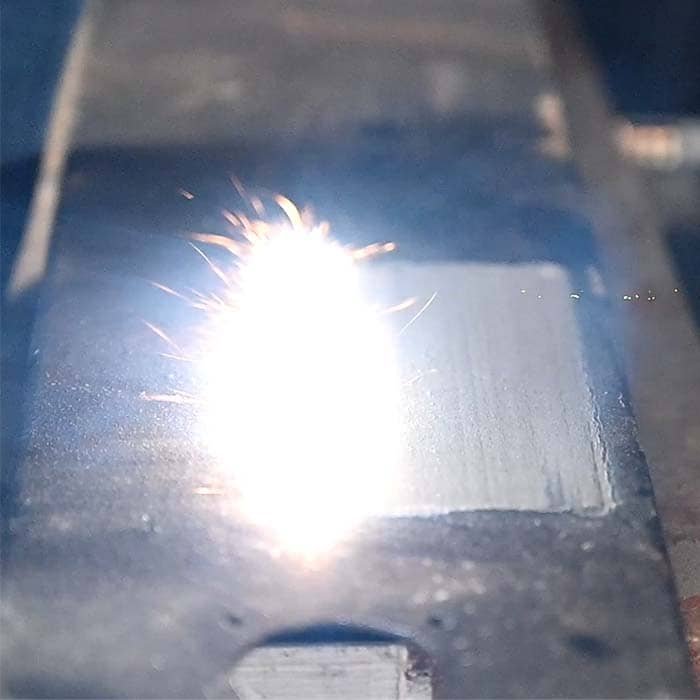

- The laser device emits a concentrated beam of light energy at the target surface.

- The wavelength and pulse duration of the laser are adjusted based on the material and paint type.

Paint Layer Vaporization:

- As the laser beam contacts the painted surface, it heats the paint layers, causing them to vaporize and disintegrate.

- The process is known as ablation, where the heat energy converts the paint into gas or fine particles that can be collected by a fume extractor.

Precision Control:

- Laser settings can be precisely controlled to ensure thorough paint removal while preventing damage to the underlying surface.

- This precision makes laser paint removal ideal for delicate or detailed work.

2.2 Types of Lasers Used for Paint Removal

Fiber Lasers:

- Characteristics: Highly efficient with low maintenance requirements.

- Advantages: Provide precise control over beam intensity, making them suitable for removing thin paint layers without damaging the base material.

- Applications: Commonly used for industrial purposes where consistent, fast, and accurate removal is required.

CO2 Lasers:

- Characteristics: Emit longer wavelengths that are ideal for treating non-metallic surfaces like wood and plastics.

- Advantages: Effectively clean larger surface areas and can handle thicker coatings.

- Applications: Popular in restoration and refurbishment projects involving wooden or plastic surfaces.

Nd:YAG Lasers:

- Characteristics: Use a neodymium-doped crystal as a medium and are known for high peak power.

- Advantages: Can achieve fine detailing and are versatile across different materials.

- Applications: Commonly used for industrial cleaning, especially where varying coating thicknesses are involved.

In summary, laser paint removal for wood technology provides a highly efficient, precise, and environmentally friendly solution for stripping coatings. By selecting the appropriate laser type, businesses can achieve the best results for their specific needs.

3 Preparation Steps for Laser Paint Removal

Effective preparation is key to achieving excellent results with laser paint removal for wood. Here’s how to prepare, ensuring safety and proper treatment of wood surfaces.

3.1 Safety Measures and Equipment

Personal Protective Equipment (PPE):

- Eye Protection: Wear safety goggles or glasses with proper optical filters to protect against intense laser beams.

- Respiratory Protection: Use a mask or respirator to avoid inhaling particles and fumes during the process.

- Protective Clothing: Wear non-reflective, fire-resistant clothing to protect the skin.

Workspace Setup:

- Enclosure or Barriers: Create barriers around the laser area to prevent unauthorized access and reflect stray beams.

- Ventilation: Ensure proper ventilation or use fume extractors to remove vaporized paint particles and maintain air quality.

Laser Equipment Setup:

- Calibration and Testing: Calibrate the laser settings based on the specific type of coating and substrate, and test on a small surface area first.

- Positioning and Focus: Adjust the laser’s focal point for optimal energy delivery to the target surface.

Training and Guidelines:

- Ensure all operators are trained in safe laser handling and understand emergency shutdown procedures.

3.2 Preparing Wood Surfaces for Laser Treatment

Inspect the Wood Surface:

- Identify any areas of the wood surface that are fragile or damaged to avoid further weakening during stripping.

- Check for embedded nails, screws, or other metal objects that could reflect the laser beam.

Cleaning and Dust Removal:

- Remove dust and debris using a soft brush or vacuum to prevent interference with laser efficiency.

Masking and Protection:

- If the wood surface has sensitive areas like delicate carvings that you don’t want to strip, cover them with non-reflective masking tape or a similar material.

Test Area Application:

- Before full-scale cleaning, apply the laser to a small, inconspicuous section to observe how the wood responds.

- Adjust power and speed settings accordingly.

By following these preparation steps, you can ensure safe and efficient laser paint removal, preserving the wood’s integrity while achieving high-quality results.

4 Detailed Guide to the Laser Paint Removal Process

To achieve optimal results in laser paint removal, follow this step-by-step guide, and ensure the correct laser settings for different types of wood.

4.1 Step-by-Step Laser Application

Initial Surface Cleaning:

- Clear the surface of dust, dirt, and any loose particles to ensure effective laser application.

Test on a Small Area:

- Choose a small, less visible area to test the laser settings.

- Observe the effect on paint and the underlying wood, adjusting power and speed as necessary.

Start Laser Application:

- Begin by moving the laser slowly across the surface, maintaining a consistent distance to ensure even removal.

- Work in small sections to maintain focus and control over the removal process.

Monitor the Ablation Process:

- Carefully monitor the ablation process to ensure the laser is effectively removing the paint without damaging the wood.

- Adjust speed or intensity if the process seems too aggressive.

Fume Extraction:

- Ensure a proper fume extraction system is in place to remove vaporized particles and maintain visibility.

Complete the Removal:

- Once satisfied with the test results, continue the process systematically across the entire surface.

- Regularly inspect progress to ensure uniform stripping.

Surface Inspection and Cleaning:

- After removing the paint, inspect the surface for any remaining residue or patches.

- Clean the surface again to remove any leftover particles.

4.2 Adjusting Laser Settings for Different Wood Types

Hardwood vs. Softwood:

- Hardwood (e.g., oak, maple): Typically requires higher laser power due to its denser structure.

- Softwood (e.g., pine, cedar): Use lower power settings to prevent scorching or etching.

Wood Grain Direction:

- Adjust the laser’s angle and speed to align with the grain direction to minimize damage to the wood fibers.

Coating Thickness:

- Thick Paint Layers: Increase power or reduce speed for more intense energy application.

- Thin or Delicate Coatings: Reduce power to avoid over-stripping and potential damage to the substrate.

Surface Sensitivity:

- For wood surfaces with intricate carvings or fragile features, maintain lower power and slower speed settings to preserve the details.

By understanding these guidelines, you can confidently navigate the laser paint removal process while tailoring the settings to your specific wood type. This approach ensures that the paint is removed efficiently without compromising the wood’s integrity.

5 Comparison with Traditional Paint Removal Methods

Understanding how laser paint removal for wood stands against traditional methods like chemical stripping and sanding can help make an informed decision. Let’s compare these techniques based on key factors.

5.1 Chemical Strippers vs. Laser Removal

Efficiency:

Chemical Strippers:

- Often require multiple applications for thick or stubborn paint layers.

- May leave residues that need additional cleaning.

Laser Removal:

- Provides immediate results by vaporizing the paint on contact.

- No need for extra cleaning due to its dust-free operation.

Environmental Impact:

Chemical Strippers:

- Contain hazardous substances that can be harmful if not disposed of properly.

- Require protective gear due to the risk of inhalation and skin irritation.

Laser Removal:

- Produces no hazardous waste and minimal fumes.

- Only requires proper ventilation to manage vaporized particles.

Surface Integrity:

Chemical Strippers:

- Can be too aggressive for delicate surfaces, causing damage or discoloration.

- Potentially softens or degrades the wood fibers.

Laser Removal:

- Precisely controlled to target paint without damaging the substrate.

- Ideal for detailed or intricate work due to its focused beam.

5.2 Sanding vs. Laser Techniques

Time and Labor:

Sanding:

- Manually intensive and time-consuming, especially for larger surfaces.

- Requires different sandpaper grits for various stages, adding to the effort.

Laser Techniques:

- Significantly reduces labor due to its automated and consistent application.

- Efficiently handles large or small surfaces with minimal adjustment.

Surface Finish:

Sanding:

- Risks uneven sanding if not performed carefully.

- Can leave the surface rough or damage fine details.

Laser Techniques:

- Provides a uniform finish with its controlled and even removal process.

- Safely handles sensitive or intricate surfaces without roughening.

Cost and Maintenance:

Sanding:

- Requires frequent replacement of consumables like sandpaper.

- Needs proper ventilation and clean-up due to dust generation.

Laser Techniques:

- High initial investment but offers long-term savings due to reduced labor and no consumable costs.

- Minimal maintenance due to robust equipment and controlled operation.

Overall, laser paint removal outshines traditional methods due to its speed, precision, and eco-friendliness, making it a superior choice for many restoration and maintenance projects.

6 Advantages of Laser Paint Removal on Wood

Laser paint removal for wood offers significant benefits over traditional methods, particularly when it comes to working with wooden surfaces. Here are some key advantages:

6.1 Precision and Control in Paint Removal

Targeted Application:

- Laser beams can be focused on specific areas for selective paint removal.

- Ideal for intricate details or carvings where precise control is necessary.

Adjustable Intensity:

- Power and speed settings can be fine-tuned to the specific wood type and paint thickness.

- Ensures thorough removal without over-stripping or damaging the substrate.

Layer-by-Layer Removal:

- The laser can be adjusted to vaporize paint layer by layer.

- Particularly useful for removing multiple layers of paint without affecting the underlying wood.

No Surface Roughening:

- Maintains the smooth texture of the wood since it works without physical abrasion.

- Great for surfaces that need to be repainted or refinished after stripping.

6.2 Environmental Benefits and Reduced Cleanup

No Chemicals or Consumables:

- Eliminates the need for hazardous chemicals, reducing exposure risks and disposal challenges.

- Requires no additional materials like sandpaper or scrapers.

Minimal Residue and Waste:

- The ablation process vaporizes the paint into fine particles that can be safely extracted.

- Leaves no residual chemical contaminants or sanding dust on the wood.

Reduced Cleanup Time:

- The laser’s precision reduces the amount of leftover debris.

- Fume extractors and containment systems efficiently collect any vaporized particles, leaving a clean surface.

Energy Efficiency:

- Modern laser systems are designed to consume less energy during operation.

- The focused beam minimizes heat dispersion, making the process more efficient.

These advantages make laser paint removal a compelling choice for anyone seeking an effective, eco-friendly, and safe solution for restoring or maintaining wooden surfaces.

7 Case Studies: Successful Laser Paint Removal Projects

Laser paint removal has been applied successfully across various sectors, offering unique advantages in both residential and commercial settings.

7.1 Residential Applications

Restoring Antique Furniture:

- Problem: Antique furniture had multiple layers of old paint and varnish that needed careful removal.

- Solution: Laser technology was used to strip the layers without damaging the intricate wood carvings.

- Outcome: The furniture was restored to its natural wood finish, preserving its original charm for refinishing.

Deck and Porch Renovation:

- Problem: A homeowner’s wooden deck was peeling due to old, thick layers of paint.

- Solution: The laser removed the layers without affecting the deck structure, reaching into crevices that traditional methods couldn’t.

- Outcome: The deck was ready for a fresh coat of paint, which adhered well to the smooth surface left by the laser.

7.2 Commercial and Industrial Use Cases

Industrial Machinery Restoration:

- Problem: Manufacturing machinery had accumulated layers of paint, grease, and rust, hindering proper maintenance.

- Solution: Laser technology cleaned the machinery, stripping paint and removing grime without disassembling the equipment.

- Outcome: The machinery’s surface was restored, extending its operational lifespan with minimal downtime.

Historical Building Conservation:

- Problem: The exterior woodwork of a historical monument was deteriorating under chipped, old paint.

- Solution: Laser systems removed the old layers without damaging the original woodwork, maintaining the historical accuracy.

- Outcome: The cleaned surfaces enabled restorers to apply a new finish that respected the monument’s architectural heritage.

Aircraft Maintenance:

- Problem: An airline needed to strip old paint from aircraft without compromising the lightweight aluminum panels.

- Solution: A laser system removed paint while leaving the metal panels intact, maintaining structural integrity.

- Outcome: The aircraft was repainted and reassembled quickly, reducing maintenance turnaround time.

These case studies underscore how laser paint removal provides versatile and precise solutions in varied applications. Whether for preserving heritage or ensuring operational efficiency, the technology continues to prove its worth across industries.

8 Troubleshooting Common Issues in Laser Paint Removal

Laser paint removal can sometimes pose challenges that require careful troubleshooting to maintain effectiveness and surface integrity. Here are practical solutions to common issues encountered during the process.

8.1 Addressing Incomplete Paint Removal

Check Laser Power Settings:

- Problem: The laser may not fully remove the paint layer.

- Solution: Increase the laser power to deliver higher energy per pulse. Test adjustments on a small area first to avoid damaging the wood.

Adjust Beam Speed:

- Problem: Paint remains due to the laser moving too quickly across the surface.

- Solution: Slow down the beam speed to allow sufficient exposure time on each section.

Revisit Focal Point Positioning:

- Problem: A misaligned focal point may cause inefficient energy delivery.

- Solution: Refocus the laser head to achieve an optimal focal length on the target surface.

Multiple Passes:

- Problem: Thicker paint layers may need more than one pass for complete removal.

- Solution: Make additional passes after adjusting settings to address remaining areas.

8.2 Handling Heat Effects on Wood

Adjust Power Levels:

- Problem: High laser power can cause scorching or charring on wood surfaces.

- Solution: Reduce the power level to minimize excess heat buildup and test on a small area first.

Increase Movement Speed:

- Problem: Slow movement may overexpose wood to the laser beam, resulting in discoloration.

- Solution: Increase movement speed to prevent prolonged heat exposure.

Maintain Proper Ventilation:

- Problem: Poor ventilation can cause localized heating due to accumulated fumes and particles.

- Solution: Ensure proper fume extraction to keep the surface clear and cool during laser application.

Use Cooling Methods:

- Problem: Extended exposure to the laser can heat up the wood surface.

- Solution: Use external cooling measures like airflow or misting to dissipate excess heat.

Test Different Laser Types:

- Problem: Some wood types are more sensitive to specific laser wavelengths.

- Solution: Experiment with different laser types (e.g., fiber vs. CO2) to find the most suitable wavelength for a particular wood surface.

By following these troubleshooting steps, you can optimize the laser paint removal process to achieve efficient, damage-free results on wood surfaces.

9 Maintenance and Care After Laser Paint Removal

Proper maintenance and care following laser paint removal are crucial to preserving and enhancing the quality of the treated surface. Here are some steps for post-removal treatments and tips for long-term care.

9.1 Post-removal Surface Treatments

Surface Cleaning:

- Residue Removal: Gently wipe the surface to remove any dust or paint residue left after laser ablation.

- Fume Extraction Residue: If a fume extraction system was used, ensure no condensation or particles remain on the wood.

Inspect for Damage:

- Check Surface Integrity: Look for any charred or scorched areas that may need light sanding.

- Structural Weaknesses: Verify that no structural integrity issues were caused by the removal process.

Re-sealing or Re-painting:

- Sealing: Apply a wood sealer to protect the surface and prevent moisture absorption.

- Re-painting: If repainting is planned, use a suitable primer to prepare the wood and then apply the new paint.

Staining:

- Wood Stains: Apply a wood stain to enhance the natural grain or change the wood’s color before sealing.

9.2 Long-term Care Tips for Laser-treated Wood

Regular Inspection:

- Surface Checks: Periodically inspect the wood for any signs of peeling, discoloration, or moisture damage.

- Joint and Structural Integrity: Check joints, corners, and structural points to ensure stability.

Environmental Protection:

- UV Exposure: Use UV-protective finishes if the wood will be exposed to sunlight.

- Moisture Control: Keep the surface dry and well-ventilated to prevent mold growth or rotting.

Routine Cleaning:

- Gentle Cleaning: Clean the surface with a mild detergent and a soft cloth to maintain its appearance.

- Avoid Abrasives: Do not use abrasive cleaning pads that might scratch or dull the surface.

Preventative Coating Reapplication:

- Sealers and Stains: Reapply sealers or stains every few years to maintain the wood’s finish and protection.

- Re-painting: If painted, regularly repaint to keep the surface protected.

Temperature and Humidity Control:

- Wood Expansion: Minimize extreme temperature fluctuations and humidity changes that may cause the wood to expand or contract.

Implementing these care practices ensures that wood treated with laser paint removal retains its quality and appearance for years to come.

10 Future of Laser Technology in Paint Removal

The future of laser technology in paint removal promises exciting innovations that enhance efficiency, precision, and sustainability. Here’s a look at upcoming advancements and eco-friendly trends.

10.1 Innovations in Laser Removal Equipment

Increased Portability:

- Compact Systems: Development of smaller, lighter laser systems will allow for easier transport and use in confined spaces.

- Field Applications: Portable designs make it easier to conduct on-site work for large structures, historical restorations, and machinery.

Automation and AI Integration:

- Automated Calibration: Systems will automatically calibrate laser settings based on surface and paint properties.

- Smart Scanning: AI-enhanced scanners will identify paint layers and adjust laser intensity to optimize removal without damaging the substrate.

Enhanced Safety Features:

- Real-time Monitoring: Advanced sensors will monitor heat levels and surface conditions to prevent scorching or overexposure.

- Remote Control: Operators can monitor and control laser systems remotely, ensuring precise operation while maintaining a safe distance.

Multi-Laser Platforms:

- Hybrid Systems: Future platforms may include multiple laser types (e.g., fiber and CO2) to cater to different substrates, offering versatile applications in one unit.

10.2 Trends in Eco-friendly Surface Treatments

Chemical-free Solutions:

- No Chemicals: Lasers will continue to eliminate the need for chemical stripping, reducing hazardous waste and environmental contamination.

- Low Particulate Emissions: Innovations will focus on reducing particulate emissions, making the ablation process cleaner.

Energy Efficiency:

- Lower Power Consumption: Equipment will be designed for higher efficiency with lower energy requirements, reducing the carbon footprint.

- Optimized Ablation Rates: Better ablation rates will minimize the exposure time needed for each surface, resulting in less overall energy use.

Surface Restoration Synergy:

- Protective Coatings: Integration with protective coating systems will enhance the longevity and appearance of the cleaned surfaces.

- Zero Waste Systems: Combining laser technology with fume extraction will capture and recycle ablated materials, creating zero-waste processes.

Cross-industry Adoption:

- Wider Applications: As the technology becomes more accessible, it will find use in non-traditional industries such as art conservation, consumer electronics, and medical equipment sterilization.

These future advancements are set to transform laser paint removal into a more efficient, safer, and eco-friendly method that caters to a broader range of applications.

11 Choosing the Right Laser Equipment for Paint Removal

Selecting the best laser equipment for paint removal requires a clear understanding of your project’s needs and matching them to the features available in different machines. Here are key factors to consider and some recommended models and manufacturers.

11.1 Factors to Consider When Buying a Laser Machine

Power Output:

- Low-Power Lasers (20-50W): Ideal for small-scale projects on delicate surfaces like antiques, artworks, and softwood furniture.

- Mid-Range Power (50-500W): Suitable for general-purpose stripping on metal, hard wood, and machinery.

- High-Power Lasers (500W+): Best for industrial-scale stripping, heavy rust removal, and thick paint coatings.

Beam Type:

- Fiber Lasers: Efficient for metals, fast processing, high precision.

- CO2 Lasers: Effective for non-metals like wood and plastic, less heat damage.

Adjustability and Control:

- Pulse Settings: Variable pulse frequency to handle different paint thicknesses and substrates.

- Beam Width: Adjustable to cover larger surfaces or focus on fine details.

Portability:

- Compact Design: Lightweight units for ease of use on-site or confined spaces.

- Wheeled Units: Mobile systems with wheels to transport between job sites.

Safety Features:

- Fume Extraction: Integrated systems to capture and filter ablation fumes.

- Protective Enclosures: Enclosures to shield operators from direct exposure.

Budget and ROI:

- Initial Investment: Compare models to find the right balance between features and cost.

- Operating Costs: Consider maintenance, energy consumption, and parts replacement.

11.2 Recommended Models and Manufacturers

CleanTech by Laser Photonics:

- Features: Offers compact and industrial models with fiber laser technology and adjustable pulse settings.

- Use Cases: Ideal for automotive, aerospace, and heavy machinery industries.

Rust Buster by Allied Scientific Pro:

- Features: High-power fiber laser with integrated fume extraction and multi-language support.

- Use Cases: Suited for rust removal, paint stripping, and industrial machinery refurbishment.

CL-Fiber by Clean-Lasersysteme:

- Features: Advanced safety enclosures, versatile pulse settings, and high-precision beam control.

- Use Cases: Effective in large-scale industrial paint removal and delicate restoration projects.

LaserEvo by P-Laser:

- Features: Wheeled units, variable power output, and modular design for easy upgrades.

- Use Cases: Suitable for historic restoration, aviation, and precision cleaning.

Chihalo by Chihalo Tech:

- Features: Customization options, one-to-one technical support, and versatile power ranges.

- Use Cases: Offers tailor-made solutions for paint stripping, mold cleaning, and surface preparation.

12 Conclusion and Final Thoughts on Laser Paint Removal for Wood

12.1 Summary of Benefits

Precision and Control:

- Lasers provide exceptional control over paint removal, especially on delicate wood surfaces, ensuring minimal damage.

Efficiency:

- The ability to remove paint quickly and consistently makes lasers highly efficient, reducing project timelines.

Environmental Impact:

- Chemical-free laser treatment significantly reduces waste and pollutants, promoting a greener approach.

Surface Versatility:

- From softwoods to hardwoods, laser paint removal adapts to different wood types without the need for separate equipment.

Reduced Cleanup:

- With minimal debris and residues left behind, the post-removal cleaning process is simplified.

12.2 Final Recommendations for Prospective Users

Assess Project Requirements:

- Understand the nature of your wood surfaces, including type, age, and existing coatings, to select the right laser system.

Balance Budget and Features:

- Consider a laser system that aligns with your needs and budget, ensuring the best return on investment.

Consult a Professional:

- Seek advice from experts or manufacturers to identify equipment that best fits your specific paint removal needs.

Test Before Full Application:

- Conduct tests on a small section to fine-tune laser settings and confirm optimal results.

Prioritize Safety:

- Invest in safety gear, follow operational protocols, and ensure proper fume extraction for a secure working environment.

Consider Long-term Maintenance:

- Regularly maintain the laser equipment and follow care guidelines to prolong its lifespan and ensure consistent performance.

Laser paint removal for wood offers a cutting-edge solution that is both effective and sustainable. By understanding its strengths and limitations, prospective users can confidently adopt this technology for their wood treatment projects.