Table des matières

1.Introduction to Laser Light Rust Removal

Laser light rust removal is an advanced technology that utilizes high-intensity laser beams to clean and remove rust from metal surfaces. This method is gaining popularity in various industries due to its efficiency, precision, and environmental benefits. Unlike traditional rust removal methods, laser cleaning offers a non-abrasive, contact-free solution that ensures the integrity of the underlying material.

1.1 Overview of Laser Technology in Rust Removal

- How It Works

Laser rust removal works by directing laser pulses onto the rusted surface. The energy from the laser is absorbed by the rust layer, causing it to heat up rapidly and vaporize or break away from the base material. This process can be controlled precisely to ensure that only the rust is removed, leaving the underlying metal intact.

- Types of Lasers Used

– Continuous Wave Lasers: Emit a continuous laser beam and are typically used for large-scale cleaning where high power is required.

– Pulsed Lasers: Emit laser pulses in short bursts, allowing for greater control and precision. These are ideal for delicate surfaces or detailed cleaning tasks.

- Equipment

Laser rust removal systems generally consist of the following components:

– Laser Source: Generates the laser beam.

– Optical System: Focuses and directs the laser beam onto the target surface.

– Control System: Allows operators to adjust parameters such as power, pulse duration, and scanning speed.

– Safety Features: Includes protective enclosures, safety interlocks, and personal protective equipment (PPE) for operators.

1.2 Benefits of Using Laser for Rust Cleaning

- Precision and Control

– Selective Cleaning: Lasers can be adjusted to remove rust without affecting the underlying material.

– High Accuracy: Suitable for intricate and complex surfaces where traditional methods might struggle.

- Non-Abrasive and Non-Contact

– Material Preservation: Prevents mechanical damage to the substrate, maintaining the integrity of the original material.

– No Wear and Tear: Unlike abrasive methods, laser cleaning equipment does not wear out the surface.

- Environmental Friendliness

– No Chemicals or Solvents: Eliminates the need for hazardous chemicals, making it a safer and more environmentally friendly option.

– Minimal Waste: Produces less waste compared to traditional rust removal methods.

- Efficiency and Speed

– Fast Cleaning: Capable of removing rust quickly, reducing downtime in industrial applications.

– Automatable: Can be integrated into automated systems for continuous and consistent cleaning.

- Versatility

– Wide Range of Applications: Effective on various metals and suitable for different industries including automotive, aerospace, maritime, and manufacturing.

– Adaptable Technology: Can be used for other cleaning tasks such as removing paint, oil, and contaminants.

- Safety

– Reduced Exposure to Harmful Substances: Operators are not exposed to hazardous chemicals or abrasive particles.

– Improved Work Environment: Cleaner and safer working conditions.

- Cost-Effective

– Long-Term Savings: Reduced need for consumables and lower maintenance costs over time.

– Increased Productivity: Faster cleaning times lead to higher throughput and operational efficiency.

1.3 Conclusion

Laser light rust removal represents a significant advancement in cleaning technology, offering a precise, efficient, and environmentally friendly solution for rust removal. Its benefits, including high accuracy, non-abrasive nature, and adaptability, make it an ideal choice for various industries looking to improve their maintenance processes and reduce environmental impact. As technology continues to evolve, laser rust removal is set to become a standard practice in industrial cleaning and maintenance.

2.Understanding the Technology Behind Laser Rust Removal

Laser rust removal leverages advanced laser technology to clean metal surfaces by vaporizing rust without damaging the underlying material. This method is highly effective, environmentally friendly, and precise, making it an attractive alternative to traditional rust removal techniques.

2.1 How Laser Rust Removal Works

- Basic Principle

Laser rust removal operates on the principle of laser ablation. Laser ablation involves directing a focused laser beam onto a rusted surface, causing the rust to absorb the laser energy. This absorption leads to rapid heating, vaporization, or sublimation of the rust layer, effectively removing it from the metal surface.

- Steps in the Process

- Laser Emission: The laser source generates a beam of coherent light.

- Focusing the Beam: The optical system focuses the laser beam onto the rusted area, ensuring high energy concentration.

- Absorption and Heating: The rust absorbs the laser energy, leading to rapid heating.

- Vaporization or Sublimation: The intense heat causes the rust to vaporize or sublimate, leaving the underlying metal clean.

- Removal of Debris: The vaporized rust is often removed by a vacuum system or simply blown away by a stream of air.

- Control and Precision

– Adjustable Parameters: Laser power, pulse duration, and scanning speed can be precisely controlled to match the type and thickness of the rust.

– Selective Removal: By adjusting these parameters, the laser can selectively remove rust without affecting the base metal, ensuring the integrity of the surface.

- Advantages

– No Mechanical Contact: Prevents physical wear and tear on the metal surface.

– No Chemical Use: Eliminates the need for harmful chemicals, making the process safer and more environmentally friendly.

– Minimal Heat Affected Zone (HAZ): The rapid heating and cooling minimize thermal distortion or damage to the substrate.

2.2 Types of Lasers Used for Rust Removal

- Continuous Wave Lasers

Characteristics:

– Emit a continuous laser beam.

– High power output, typically used for large-scale or heavy-duty cleaning tasks.

Applications:

– Suitable for extensive rust removal on large metal structures such as ship hulls, bridges, and industrial equipment.

Benefits:

– High-speed cleaning.

– Effective for removing thick layers of rust.

- Pulsed Lasers

Characteristics:

– Emit laser beams in short, high-intensity pulses.

– Allows for precise control over the cleaning process.

Types of Pulsed Lasers:

– Nanosecond Pulsed Lasers: Short pulses in the nanosecond range, suitable for general rust removal.

– Picosecond and Femtosecond Pulsed Lasers: Ultra-short pulses that provide extremely precise cleaning, ideal for delicate surfaces.

Applications:

– Used for detailed and precision cleaning tasks, such as automotive parts, aerospace components, and intricate machinery.

Benefits:

– Greater control and precision.

– Minimizes heat input, reducing the risk of thermal damage.

- Fiber Lasers

Characteristics:

– Utilize fiber optic cables to deliver the laser beam.

– Highly efficient and capable of producing both continuous and pulsed outputs.

Applications:

– Versatile and can be used for a wide range of rust removal tasks, from large structures to detailed components.

Benefits:

– High beam quality and stability.

– Low maintenance and long operational life.

- CO2 Lasers

Characteristics:

– Use carbon dioxide gas as the lasing medium.

– Typically used for cutting and engraving but can be adapted for rust removal.

Applications:

– Effective for certain types of rust and specific industrial applications.

Benefits:

– High power output and efficiency.

– Suitable for non-metallic surfaces that may have rust or similar contaminants.

2.3 Conclusion

Laser rust removal technology provides a sophisticated and effective solution for rust removal, utilizing various types of lasers to cater to different applications and requirements. Understanding the technology and the types of lasers used helps in selecting the right system for specific rust removal tasks. The precision, control, and environmental benefits make laser rust removal a cutting-edge method in the field of surface cleaning and maintenance.

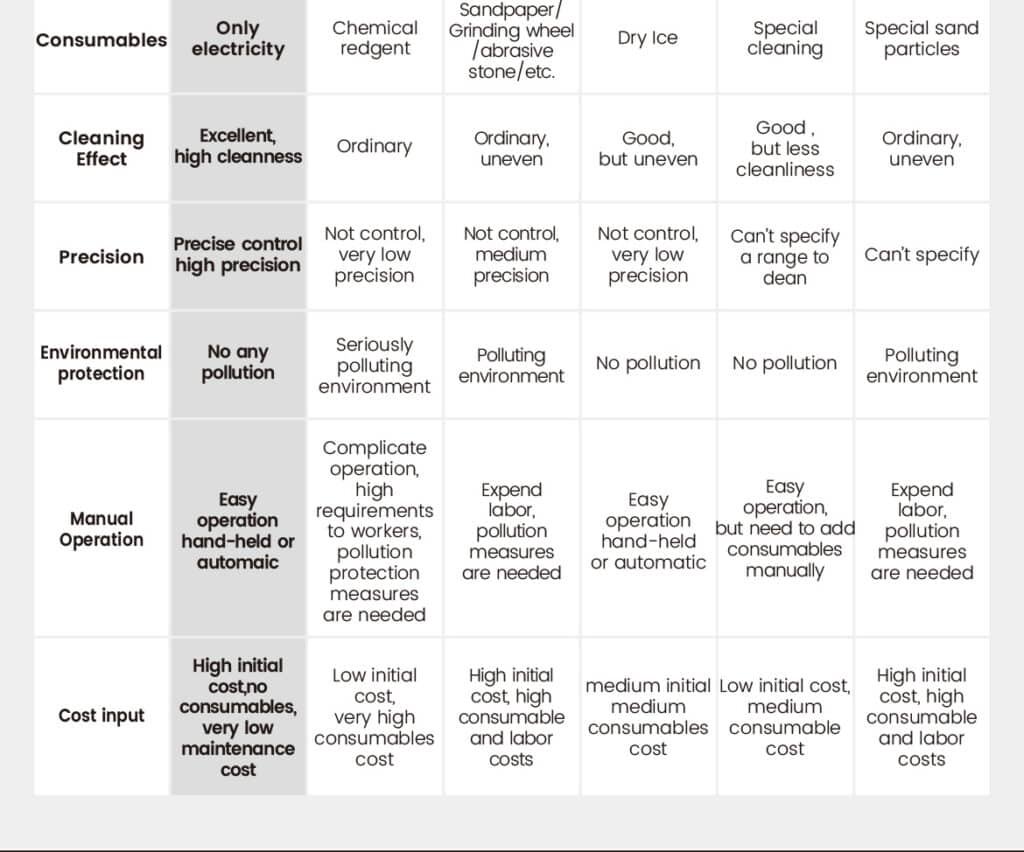

3.Comparative Analysis: Laser vs. Traditional Rust Removal Methods

3.1 Laser Rust Removal vs. Chemical Treatments

1.Laser Rust Removal

Process: Utilizes high-intensity laser beams to vaporize or ablate rust from metal surfaces.

Advantages:

– Precision and Control: Offers precise rust removal without damaging the underlying metal.

– Environmentally Friendly: Does not use harmful chemicals, producing minimal waste and reducing environmental impact.

– Non-Abrasive: Prevents mechanical wear and tear on the metal surface.

– Safety: Reduces exposure to hazardous substances and improves workplace safety.

– Efficiency: Fast cleaning process with adjustable parameters for different rust thicknesses.

Disadvantages:

– Initial Cost: Higher upfront investment in equipment.

– Training: Requires specialized training for operators.

2.Chemical Treatments

Process: Involves applying chemical solutions (such as acids, alkalis, or rust converters) to dissolve or convert rust.

Advantages:

– Widespread Availability: Chemical rust removers are widely available and easy to use.

– Cost: Lower initial cost compared to laser systems.

Disadvantages:

– Environmental Impact: Generates hazardous waste and can pollute the environment.

– Safety: Chemicals can be dangerous to handle, requiring protective gear and proper disposal methods.

– Surface Damage: Risk of damaging the underlying metal if not used correctly.

– Residue: May leave chemical residues that need further cleaning.

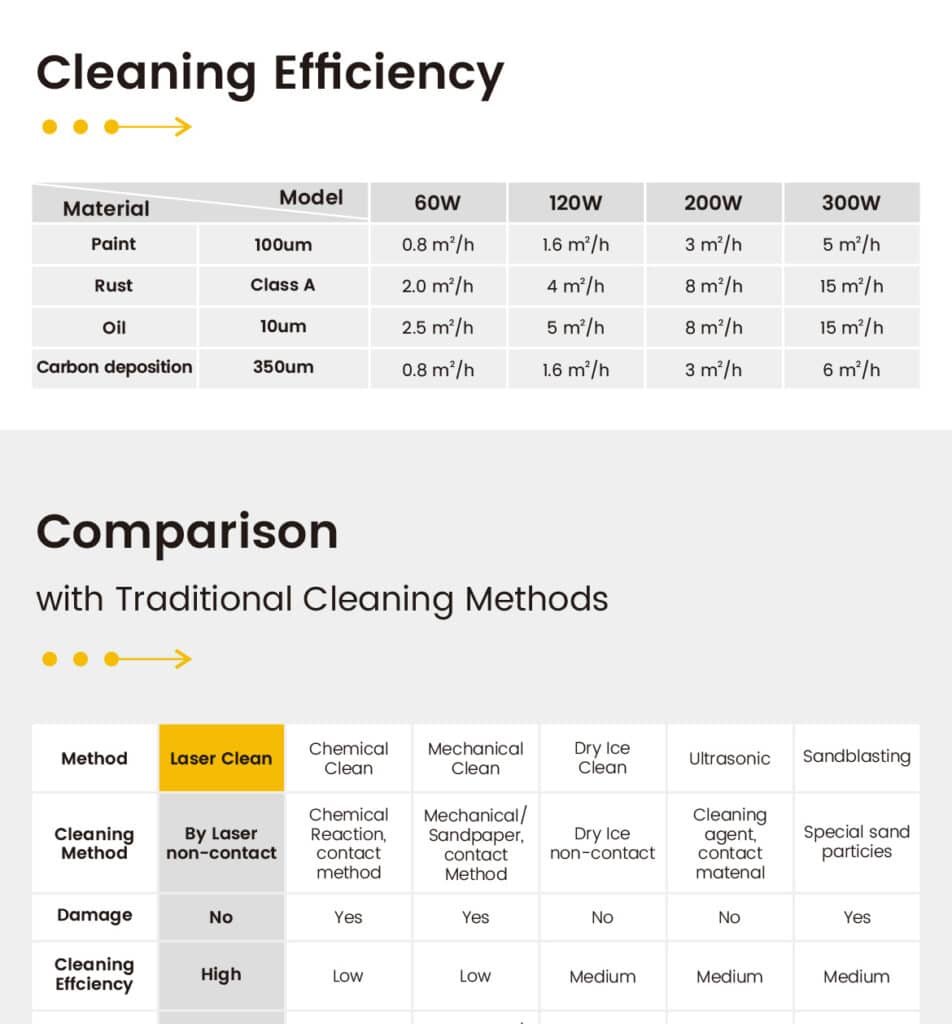

3.2 Efficiency Comparison: Laser Technology and Mechanical Methods

- Laser Technology

Efficiency:

– Speed: High-speed rust removal with minimal downtime.

– Automation: Can be integrated into automated systems for continuous and consistent cleaning.

– Energy Consumption: Generally energy-efficient, especially with advancements in fiber lasers.

Mechanical Methods (e.g., Sandblasting, Grinding)

Process: Uses abrasive materials or mechanical tools to physically remove rust.

Advantages:

– Effectiveness: Highly effective for removing thick, stubborn rust layers.

– Versatility: Suitable for various surfaces and can handle heavy-duty rust removal tasks.

Disadvantages:

– Surface Damage: Can cause abrasion and wear on the metal surface, potentially leading to material loss or structural weakening.

– Dust and Debris: Generates a significant amount of dust and debris, requiring additional cleanup and protective measures.

– Noise: Mechanical methods are typically noisy, contributing to a less favorable working environment.

– Manual Labor: Often labor-intensive and time-consuming.

3.3 Conclusion

Laser rust removal technology stands out for its precision, environmental benefits, and ability to preserve the integrity of metal surfaces. While the initial investment may be higher compared to chemical treatments and mechanical methods, the long-term benefits and operational efficiency make it a superior choice for many applications. Chemical treatments, while cost-effective and easy to use, pose significant environmental and safety concerns. Mechanical methods are effective for heavy-duty rust removal but can cause surface damage and require intensive labor. Overall, laser rust removal offers a modern, efficient, and sustainable solution for rust removal across various industries.

4.Applications of Laser Rust Removal

Laser rust removal is a versatile and efficient technology used in various industries for maintaining and restoring metal surfaces. Its precision, environmental benefits, and non-destructive nature make it suitable for a wide range of applications.

4.1 Industrial Applications of Laser Rust Cleaning

- Manufacturing and Fabrication

– Equipment Maintenance: Laser cleaning is used for maintaining manufacturing equipment by removing rust and other contaminants, ensuring optimal performance and longevity.

– Tool Cleaning: Precision tools and dies can be cleaned without damaging their intricate features.

– Surface Preparation: Laser cleaning prepares metal surfaces for subsequent processes like welding, coating, or painting by removing rust, oxides, and contaminants.

- Aerospace Industry

– Aircraft Maintenance: Laser rust removal is used to clean and maintain aircraft components, ensuring they are free from rust and corrosion, which can affect performance and safety.

– Engine Parts: Precision cleaning of engine parts and components helps maintain efficiency and reliability.

- Marine Industry

– Ship Hull Cleaning: Laser cleaning is effective for removing rust from ship hulls and other marine structures, preventing corrosion and maintaining structural integrity.

– Maintenance of Offshore Structures: Oil rigs and other offshore installations benefit from laser cleaning to manage rust and extend their operational life.

- Power Generation

– Turbine Maintenance: Laser rust removal is used to clean turbines and other components in power plants, ensuring efficient operation and reducing downtime.

– Pipeline Cleaning: Rust and other contaminants can be removed from pipelines, enhancing their longevity and preventing leaks.

- Rail Industry

– Track Maintenance: Laser cleaning is used to remove rust from railway tracks, ensuring smooth and safe operation.

– Rolling Stock Maintenance: Train components, including wheels and undercarriages, are cleaned to prevent rust and corrosion.

4.2 Use in Automotive Restoration and Maintenance

- Restoration of Classic Cars

– Body Panels: Laser rust removal is used to clean rust from body panels, frames, and other components without damaging the underlying metal, making it ideal for restoring classic cars.

– Detail Work: Precision cleaning allows for the restoration of intricate parts and areas that are difficult to reach with traditional methods.

- Maintenance of Modern Vehicles

– Chassis Cleaning: Removing rust from the chassis and other structural components helps maintain the vehicle’s integrity and safety.

– Brake Components: Laser cleaning can be used to maintain brake components by removing rust and ensuring optimal performance.

- Paint Preparation

– Surface Preparation: Laser cleaning prepares metal surfaces for painting by removing rust, old paint, and contaminants, ensuring better adhesion and a smoother finish.

– Undercoating Removal: Old undercoating can be removed efficiently, preparing the surface for new protective coatings.

- Engine and Mechanical Parts

– Engine Blocks: Cleaning rust from engine blocks and other mechanical parts helps improve performance and extend their lifespan.

– Transmission and Differential Housings: Laser cleaning ensures these components are free from rust and contaminants, improving reliability and efficiency.

4.3 Conclusion

Laser rust removal technology offers numerous advantages across a variety of industrial and automotive applications. Its precision, efficiency, and environmentally friendly nature make it an ideal choice for maintaining and restoring metal surfaces. From heavy industrial machinery and aerospace components to classic car restoration and modern vehicle maintenance, laser rust removal provides a superior alternative to traditional rust removal methods, enhancing the longevity and performance of metal parts and structures.

5.Step-by-Step Guide to Laser Rust Removal

Laser rust removal is a precise and efficient method for cleaning rust from metal surfaces. This guide outlines the steps to prepare surfaces for laser cleaning and provides a detailed procedure for the laser rust removal process.

5.1 Preparing Surfaces for Laser Cleaning

- Assessment and Inspection

– Identify Areas: Determine the areas that require rust removal.

– Evaluate Surface Condition: Assess the extent of rust and the condition of the underlying metal.

– Determine Laser Parameters: Based on the assessment, choose appropriate laser settings such as power, pulse duration, and scanning speed.

- Safety Preparations

– Personal Protective Equipment (PPE): Ensure that operators wear appropriate PPE, including safety goggles, gloves, and protective clothing.

– Safety Barriers: Set up safety barriers and warning signs around the work area to prevent unauthorized access.

– Ventilation: Ensure proper ventilation to remove fumes and particles generated during the cleaning process.

– Fire Safety: Have fire extinguishing equipment on hand, as laser cleaning can sometimes generate sparks.

- Surface Preparation

– Clean the Surface: Remove loose debris, dirt, and grease from the surface to be cleaned. This can be done using a mild detergent and water, followed by drying the surface thoroughly.

– Secure the Workpiece: Ensure the workpiece is securely fixed in place to prevent movement during the cleaning process.

5.2 Detailed Procedure of Laser Rust Removal

- Setting Up the Laser Cleaning System

– Power Up: Turn on the laser cleaning system and allow it to initialize.

– Select Parameters: Input the pre-determined laser parameters (power, pulse duration, scanning speed) into the control system.

– Focus the Laser: Adjust the optical system to focus the laser beam precisely on the rusted area.

- Conducting a Test Run

– Test Area: Select a small, inconspicuous area of the workpiece to conduct a test run.

– Adjust Settings: Fine-tune the laser settings based on the results of the test run to ensure optimal rust removal without damaging the underlying metal.

- Laser Rust Removal Process

– Begin Cleaning: Position the laser nozzle at the starting point of the rusted area.

– Scan the Surface: Move the laser beam across the rusted surface in a controlled and consistent manner. Ensure even coverage by overlapping the laser passes slightly.

– Monitor the Process: Continuously monitor the process to ensure effective rust removal and adjust the laser parameters if necessary.

- Post-Cleaning Inspection

– Inspect the Surface: After completing the cleaning process, inspect the surface to ensure all rust has been removed and the underlying metal is intact.

– Touch-Up Cleaning: If any rust spots remain, perform touch-up cleaning with the laser to achieve a completely clean surface.

- Final Steps

– Clean Residues: Use a vacuum or compressed air to remove any loose rust particles or debris from the surface.

– Surface Protection: Apply a protective coating or paint to the cleaned surface to prevent future rust formation.

5.3 Tips for Optimal Results

– Consistent Movement: Maintain a consistent speed and distance when moving the laser nozzle to ensure uniform cleaning.

– Parameter Adjustment: Be prepared to adjust laser parameters based on the specific rust and metal type.

– Regular Maintenance: Keep the laser cleaning equipment well-maintained and calibrated for optimal performance.

5.4 Conclusion

Laser rust removal is a highly effective and precise method for cleaning rust from metal surfaces. By following this step-by-step guide, you can prepare surfaces correctly, conduct the laser cleaning process efficiently, and achieve optimal results. With proper safety measures and attention to detail, laser rust removal can significantly enhance the longevity and appearance of metal parts and structures.

6.Safety Protocols and Equipment for Laser Rust Removal

Laser rust removal involves using high-intensity laser beams, which can pose various safety risks if not managed correctly. This guide outlines essential safety protocols and equipment necessary to ensure safe operation during laser rust removal.

6.1 Safety Measures During Laser Operation

- Laser Safety Training

– Comprehensive Training: Ensure all operators receive thorough training on laser safety, including understanding the specific risks associated with the type of laser used.

– Regular Refresher Courses: Conduct regular training updates to keep operators informed about new safety procedures and technologies.

- Controlled Access

– Restricted Area: Designate a specific area for laser rust removal and restrict access to authorized personnel only.

– Warning Signs: Post warning signs around the designated area to alert others of potential laser hazards.

- Laser Enclosures and Barriers

– Enclosed Systems: Use laser cleaning systems that come with protective enclosures to contain the laser beam and prevent accidental exposure.

– Safety Barriers: Set up physical barriers or curtains around the work area to block any stray laser beams.

- Ventilation and Fume Extraction

– Proper Ventilation: Ensure the work area is well-ventilated to dissipate any fumes or vapors generated during the laser cleaning process.

– Fume Extractors: Use local exhaust ventilation systems or fume extractors to capture and remove hazardous particles from the air.

- Fire Safety

– Fire Extinguishers: Keep appropriate fire extinguishers (e.g., CO2 or dry powder) readily accessible in the work area.

– Fire Watch: Assign a fire watch during operations, especially when working with materials that could ignite from laser sparks.

6.2 Required Safety Gear and Compliance Standards

- Personal Protective Equipment (PPE)

– Laser Safety Goggles: Wear laser safety goggles that match the wavelength of the laser being used to protect eyes from direct and reflected beams.

– Protective Clothing: Use flame-resistant clothing to protect against sparks and heat generated during the cleaning process.

– Gloves: Wear heat-resistant and cut-resistant gloves to protect hands from exposure to heat and sharp edges.

– Respiratory Protection: Use respirators or masks to protect against inhaling harmful fumes and particles.

- Compliance with Safety Standards

– Laser Safety Standards: Adhere to national and international laser safety standards such as ANSI Z136 (American National Standard for Safe Use of Lasers) and IEC 60825 (International Electrotechnical Commission standard for laser safety).

– Occupational Safety and Health Administration (OSHA): Follow OSHA regulations regarding laser use and workplace safety.

– Local Regulations: Comply with any additional local regulations and guidelines related to laser operation and workplace safety.

- Safety Equipment and Features

– Emergency Shut-Off: Ensure the laser system is equipped with an easily accessible emergency shut-off switch to quickly disable the laser in case of an emergency.

– Interlocks: Use safety interlocks on laser enclosures and barriers to automatically shut off the laser if the enclosure is opened or the barrier is breached.

– Warning Lights and Alarms: Install visual and audible warning systems to indicate when the laser is in operation.

- Regular Maintenance and Inspections

– Equipment Maintenance: Regularly inspect and maintain laser equipment to ensure it is in good working condition and all safety features are functional.

– Safety Audits: Conduct periodic safety audits and risk assessments to identify and address potential hazards in the laser operation area.

6.3 Conclusion

Implementing comprehensive safety protocols and using appropriate safety equipment are critical for ensuring safe laser rust removal operations. By following these safety measures, providing proper training, and complying with relevant safety standards, you can minimize risks and create a safe working environment for all personnel involved in laser rust removal.

7.Cost Analysis of Laser Rust Removal

7.1 Initial Investment

Equipment Costs

– Laser Cleaning Machine: The initial cost of a laser cleaning machine can range from $40,000 to $200,000 depending on the power and capabilities.

– Ancillary Equipment: This includes protective gear, cooling systems, and any necessary software. Estimated cost: $5,000 – $20,000.

– Training: Professional training for operators, typically costing around $1,000 – $5,000.

Installation Costs

– Setup and Calibration: Initial setup, calibration, and integration into existing systems. Estimated cost: $2,000 – $10,000.

– Facility Modifications: Any necessary modifications to the workspace to accommodate the equipment. Estimated cost: $1,000 – $5,000.

7.2 Operating Costs

Energy Consumption

– Power Consumption: Laser cleaning machines consume between 500W and 2kW per hour. Assuming an average electricity cost of $0.12 per kWh, the hourly cost would be $0.06 – $0.24.

– Cooling Systems: Additional power consumption for cooling systems, typically 100W – 500W. Cost: $0.01 – $0.06 per hour.

Maintenance

– Regular Maintenance: Routine maintenance and replacement of parts like lenses and filters. Estimated annual cost: $2,000 – $5,000.

– Unexpected Repairs: Unforeseen repairs and downtime. Estimated annual cost: $1,000 – $3,000.

Labor Costs

– Operator Wages: The average hourly wage for skilled operators. Assuming $20 – $40 per hour, depending on location and expertise.

– Training and Certification: Ongoing training for operators to ensure efficiency and safety. Annual cost: $500 – $1,500.

7.3 Cost-Benefit Analysis of Laser Cleaning Techniques

Benefits

– Efficiency: Laser rust removal is faster than traditional methods, reducing labor costs and increasing throughput.

– Precision: High precision allows for targeted cleaning without damaging the substrate.

– Environmentally Friendly: No chemical waste, making it safer for operators and reducing disposal costs.

– Low Consumable Costs: Unlike abrasive blasting, laser cleaning does not require consumables like sand or chemicals.

Savings

– Reduced Downtime: Faster cleaning times lead to less downtime for equipment.

– Lower Disposal Costs: No hazardous waste disposal fees.

– Long-Term Durability: The longevity of laser equipment and lower maintenance costs over time.

ROI Calculation

Assume a mid-range laser cleaning machine costs $100,000 with an annual operating cost of $10,000.

– Yearly Savings from Efficiency: $50,000 (based on reduced labor and increased throughput)

– Savings from Waste Disposal: $5,000

– Total Annual Savings: $55,000

Payback Period:

7.4 Summary

Laser rust removal presents a significant initial investment but offers substantial long-term benefits and cost savings. The payback period is relatively short, around 1.8 years, making it a viable and economically sound choice for industrial applications. The environmentally friendly nature and precision of laser cleaning further enhance its attractiveness as a modern cleaning solution.

8.Case Studies: Successful Laser Rust Removal

8.1 Industrial Success Stories

Case Study 1: Automotive Manufacturing

Company: Leading Car Manufacturer in Germany

Challenge: Frequent rust buildup on tooling and machinery parts, causing production delays and high maintenance costs.

Solution: Implementation of a 1,000W laser cleaning machine.

Results:

– Efficiency: Reduced cleaning time by 70%, from 10 hours to 3 hours per week.

– Cost Savings: Decreased maintenance costs by 50%, saving approximately $100,000 annually.

– Productivity: Increased overall production efficiency by 15% due to reduced downtime.

Conclusion: The company reported a payback period of less than two years, significantly improving operational efficiency and reducing costs associated with traditional rust removal methods.

Case Study 2: Aerospace Industry

Company: Aerospace Parts Manufacturer in the United States

Challenge: Corrosion on high-value aerospace components, requiring meticulous cleaning without damaging the substrates.

Solution: Utilization of a 500W pulsed laser cleaning system.

Results:

– Precision: Achieved high-precision cleaning without damaging sensitive components.

– Safety: Eliminated the need for hazardous chemicals, improving workplace safety.

– Quality: Enhanced the longevity and performance of aerospace parts.

Conclusion: The manufacturer successfully integrated laser cleaning into their maintenance routine, ensuring compliance with stringent industry standards and improving the reliability of their products.

8.2 Impact on Restoration Projects

Case Study 3: Historical Monument Restoration

Project: Restoration of a Historic Cathedral in France

Challenge: Removing rust and corrosion from iron elements and delicate stone surfaces without causing damage.

Solution: Deployment of a 200W handheld laser cleaning device.

Results:

– Delicacy: Safely removed rust from intricate ironworks and cleaned stone surfaces without abrasion.

– Preservation: Maintained the integrity of historical materials, crucial for heritage conservation.

– Time Efficiency: Reduced restoration time by 40%, allowing the project to be completed ahead of schedule.

Conclusion: The use of laser cleaning in historical restoration provided a non-invasive solution that preserved the authenticity of the monument while enhancing the overall efficiency of the restoration process.

Case Study 4: Art Conservation

Project: Cleaning of a 19th-Century Iron Sculpture in Italy

Challenge: Removing rust and old paint layers from a delicate sculpture without causing damage.

Solution: Application of a 100W laser cleaning system tailored for art conservation.

Results:

– Non-Invasive: Successfully removed corrosion and paint without affecting the underlying metal.

– Detail Preservation: Retained intricate details and patina, important for the sculpture’s historical value.

– Environmental Benefits: Avoided the use of chemicals, aligning with green conservation practices.

Conclusion: Laser cleaning proved to be an invaluable tool in the art conservation field, providing a precise and environmentally friendly method to restore and preserve valuable artworks.

8.3 Summary

These case studies demonstrate the versatility and effectiveness of laser rust removal across various industries and applications. From enhancing industrial efficiency and reducing maintenance costs to preserving historical artifacts and artworks, laser cleaning offers a modern solution that meets the demands of precision, safety, and environmental responsibility.

9.Maintenance and Care of Laser Rust Removal Equipment

Proper maintenance and care of laser rust removal equipment are crucial for ensuring its longevity, optimal performance, and safety. Below are some routine maintenance tips and strategies for maximizing the lifespan and efficiency of your laser cleaning machines.

9.1 Routine Maintenance Tips

- Regular Cleaning and Inspection

– Optics: Regularly clean the laser lens and protective glass to prevent contamination that can affect beam quality. Use appropriate cleaning solutions and non-abrasive materials.

– Ventilation Systems: Ensure that cooling fans and air filters are clean and unobstructed to prevent overheating. Replace filters as needed.

– Housing and External Surfaces: Wipe down the machine’s exterior to remove dust and debris that could enter the system.

- Calibration and Alignment

– Beam Alignment: Periodically check and adjust the laser beam alignment to maintain precision and effectiveness.

– Power Calibration: Regularly calibrate the laser’s power output to ensure it is operating at the correct levels.

- Software and Firmware Updates

– Firmware: Keep the machine’s firmware up to date to benefit from the latest features and improvements.

– Software: Update any associated software regularly to enhance performance and security.

- Component Inspection and Replacement

– Lenses and Mirrors: Inspect for signs of wear or damage and replace them if necessary to maintain optimal laser output.

– Cables and Connectors: Check for any signs of wear, fraying, or damage to ensure reliable power and data transmission.

– Cooling System: Regularly check the cooling system for leaks or blockages and ensure it is functioning correctly.

9.2 Longevity and Performance Optimization

- Proper Usage

– Operating Conditions: Use the equipment within the recommended parameters, avoiding extreme temperatures or humid conditions.

– Duty Cycle: Adhere to the recommended duty cycle to prevent overheating and excessive wear.

- Environmental Control

– Clean Environment: Operate the machine in a clean environment to minimize dust and debris entering the system.

– Stable Power Supply: Use a stable power supply with surge protection to prevent electrical damage.

- Training and Safety

– Operator Training: Ensure all operators are adequately trained in the use and maintenance of the equipment. Regular refresher courses can help maintain high standards of operation.

– Safety Protocols: Follow all safety protocols to prevent accidents that could damage the equipment or harm operators.

- Scheduled Maintenance

– Maintenance Schedule: Implement a regular maintenance schedule based on the manufacturer’s recommendations. Document all maintenance activities for future reference.

– Professional Servicing: Arrange for periodic servicing by professional technicians to perform thorough inspections and maintenance.

- Monitoring and Diagnostics

– Performance Monitoring: Use built-in monitoring tools to track the machine’s performance and identify any potential issues early.

– Diagnostics: Run diagnostic checks regularly to ensure all systems are functioning correctly.

9.3 Summary

By following these maintenance and care guidelines, you can significantly extend the life of your laser rust removal equipment and ensure it operates at peak performance. Regular maintenance, proper usage, and environmental control are key factors in achieving longevity and efficiency. Implementing a structured maintenance schedule and providing adequate training for operators will help maintain the reliability and safety of your laser cleaning systems.

10.Choosing the Right Laser Rust Removal Service

Selecting the right laser rust removal service provider is crucial for ensuring quality results and optimal performance. Here are key criteria to consider and some top-rated services to help guide your decision.

10.1 Criteria for Selecting a Laser Cleaning Provider

- Expertise and Experience

– Industry Experience: Look for providers with extensive experience in laser cleaning, particularly in your specific industry.

– Technical Knowledge: Ensure the provider has a strong technical background and employs skilled technicians who understand the intricacies of laser rust removal.

- Equipment Quality

– Advanced Technology: Choose providers that use state-of-the-art laser cleaning machines with high precision and efficiency.

– Maintenance and Upgrades: Verify that the equipment is well-maintained and regularly updated to incorporate the latest advancements.

- Service Range

– Comprehensive Solutions: Select providers offering a full range of services, from initial assessment and testing to final cleaning and post-service inspection.

– Customization: Ensure the provider can tailor their services to meet your specific needs and requirements.

- Safety and Compliance

– Safety Standards: Confirm that the provider adheres to strict safety protocols and standards to protect workers and equipment.

– Regulatory Compliance: Ensure the provider complies with all relevant industry regulations and environmental guidelines.

- Customer Support

– Responsive Support: Opt for providers with a reputation for excellent customer service and responsiveness.

– Technical Assistance: Check if they offer ongoing technical support and training for your staff.

- Cost and Value

– Transparent Pricing: Look for providers with clear, transparent pricing structures without hidden fees.

– Value for Money: Assess the overall value offered, considering factors like quality, efficiency, and additional services.

- References and Reviews

– Customer Testimonials: Seek out testimonials and case studies from previous clients to gauge satisfaction and performance.

– Online Reviews: Check online reviews and ratings on platforms like Google, Yelp, or industry-specific forums.

10.2 Top Rated Laser Rust Removal Services

- Chihalo Laser

Overview: Chihalo Laser is renowned for its innovative laser cleaning solutions, catering to various industries, including automotive, aerospace, and manufacturing.

Key Features:

– Advanced fiber laser technology

– Customizable solutions

– High precision and efficiency

– Strong safety protocols

Customer Feedback: Highly praised for their technical expertise, customer service, and effective cleaning results.

- Adapt Laser Systems

Overview: Adapt Laser Systems specializes in providing environmentally friendly laser cleaning solutions, focusing on industrial applications.

Key Features:

– Environmentally friendly processes

– Versatile applications

– Extensive industry experience

– Comprehensive customer support

Customer Feedback: Customers appreciate their thorough approach, professionalism, and the high quality of their cleaning services.

- Clean-Lasersysteme (CleanLaser)

Overview: CleanLaser is a leader in laser cleaning technology, offering robust and efficient solutions for rust removal and surface preparation.

Key Features:

– German engineering and precision

– Wide range of laser systems

– High safety standards

– Strong focus on R&D

Customer Feedback: Known for reliability, advanced technology, and excellent customer support.

- 4JET Group

Overview: 4JET Group provides advanced laser cleaning solutions with a focus on innovation and sustainability.

Key Features:

– Innovative laser technology

– Focus on sustainability

– Customizable solutions

– Excellent training and support

Customer Feedback: Commended for their innovative approach, high-quality equipment, and responsive customer service.

- Laser Photonics

Overview: Laser Photonics offers cutting-edge laser cleaning systems for a variety of industrial applications, emphasizing efficiency and precision.

Key Features:

– High-power laser systems

– Efficient and precise cleaning

– Wide range of applications

– Strong customer service

Customer Feedback: Praised for their high-efficiency systems, knowledgeable staff, and excellent results.

10.3 Summary

Choosing the right laser rust removal service involves evaluating the provider’s expertise, equipment quality, range of services, safety standards, customer support, cost, and reputation. Top-rated providers like Laserax, Adapt Laser Systems, Clean-Lasersysteme, 4JET Group, and Laser Photonics offer advanced technology, comprehensive solutions, and strong customer support, making them excellent choices for your laser rust removal needs.

11.Future Trends in Laser Rust Removal Technology

11.1 Innovations and Upcoming Technologies in Laser Cleaning

- Higher Power and Efficiency

– Increased Power Output: Future laser cleaning systems are expected to have higher power outputs, allowing for faster and more efficient rust removal. This will be particularly beneficial for industrial applications requiring the cleaning of large surfaces or heavily corroded materials.

– Efficiency Improvements: Advances in laser technology will lead to more energy-efficient systems, reducing operating costs and environmental impact.

- Smart and Automated Systems

– Artificial Intelligence (AI) Integration: The integration of AI and machine learning will enable laser cleaning systems to adapt to different surfaces and rust levels automatically, optimizing the cleaning process in real-time.

– Automation and Robotics: Automated and robotic laser cleaning solutions will become more prevalent, allowing for precise and consistent cleaning with minimal human intervention. This will be especially useful in hazardous environments and for large-scale industrial applications.

- Portable and Compact Designs

– Portable Units: The development of more compact and portable laser cleaning systems will make the technology accessible to a wider range of industries and applications, including on-site and fieldwork.

– Battery-Powered Systems: Innovations in battery technology will lead to the creation of battery-powered laser cleaners, providing greater flexibility and mobility for operators.

- Advanced Safety Features

– Enhanced Safety Protocols: Future systems will incorporate advanced safety features such as real-time monitoring of laser emissions, automatic shut-off mechanisms, and improved protective measures for operators.

– User-Friendly Interfaces: Intuitive and user-friendly interfaces will simplify the operation of laser cleaning systems, reducing the need for extensive training and minimizing the risk of operator error.

- Environmentally Friendly Technologies

– Eco-Friendly Lasers: The development of lasers with lower environmental impact, such as those using less energy or generating less waste, will be a focus. This aligns with the global trend towards sustainability and green technologies.

– Non-Toxic Processes: Continued emphasis on non-toxic and chemical-free cleaning processes will drive innovation in laser technology.

11.2 The Future Market for Laser Rust Removal

- Growing Industrial Demand

– Automotive Industry: As automotive manufacturers increasingly adopt lightweight materials and advanced manufacturing processes, the demand for precise and efficient rust removal solutions will grow.

– Aerospace Industry: The aerospace sector will continue to invest in laser cleaning technology to maintain and refurbish high-value components, ensuring safety and performance.

– Manufacturing: General manufacturing will see a rise in the adoption of laser cleaning for maintenance, surface preparation, and rust removal to improve product quality and reduce downtime.

- Expansion in New Markets

– Heritage and Art Conservation: The application of laser cleaning in the conservation of cultural heritage and artworks will expand, driven by the need for non-invasive and precise cleaning methods.

– Renewable Energy: The renewable energy sector, including wind and solar, will utilize laser cleaning for maintenance and repair of equipment, enhancing efficiency and lifespan.

– Marine and Offshore: The marine industry will adopt laser cleaning for the maintenance of ships and offshore structures, where rust and corrosion are significant challenges.

- Increased Accessibility and Affordability

– Cost Reduction: Advances in manufacturing and technology will reduce the cost of laser cleaning systems, making them more accessible to small and medium-sized enterprises (SMEs).

– Leasing and Rental Models: The availability of leasing and rental options for laser cleaning equipment will lower the barrier to entry for businesses, allowing them to benefit from the technology without significant upfront investment.

- Technological Advancements

– Hybrid Systems: The development of hybrid laser systems that combine multiple functionalities, such as cleaning, cutting, and marking, will provide versatile solutions for various industrial applications.

– Improved Beam Quality: Advances in beam quality and control will enhance the precision and effectiveness of laser rust removal, enabling the treatment of more complex and delicate surfaces.

- Regulatory and Standardization Efforts

– Industry Standards: The establishment of industry standards and best practices for laser rust removal will drive consistency and quality across the sector.

– Regulatory Compliance: Increased regulatory focus on environmental and safety standards will promote the adoption of laser cleaning technologies that meet these requirements.

11.3 Summary

The future of laser rust removal technology is set to be shaped by innovations in power and efficiency, smart and automated systems, portable designs, advanced safety features, and environmentally friendly technologies. The market for laser rust removal is expected to grow across various industries, including automotive, aerospace, manufacturing, heritage conservation, renewable energy, and marine. Increased accessibility, cost reduction, and regulatory efforts will further drive the adoption of laser cleaning solutions, making them an integral part of modern industrial maintenance and restoration practices.

12.FAQs: Everything You Need to Know About Laser Rust Removal

12.1 Common Questions and Expert Answers

Q1: What is laser rust removal?

A1: Laser rust removal is a process that uses high-intensity laser beams to remove rust and other contaminants from metal surfaces. The laser selectively targets the rust without damaging the underlying material.

Q2: How does laser rust removal work?

A2: The laser beam is directed onto the rusted surface, where it heats and vaporizes the rust. This process is known as laser ablation. The rust is removed in layers, leaving a clean metal surface behind.

Q3: What types of lasers are used for rust removal?

A3: Fiber lasers, Nd:YAG lasers, and CO2 lasers are commonly used for rust removal. Fiber lasers are particularly popular due to their high efficiency, precision, and low maintenance requirements.

Q4: Is laser rust removal safe?

A4: Yes, laser rust removal is safe when proper safety protocols are followed. This includes wearing protective eyewear, using appropriate ventilation, and ensuring the laser equipment is operated by trained personnel.

Q5: Can laser rust removal be used on all metals?

A5: Laser rust removal can be used on most metals, including steel, aluminum, iron, and copper. The process is particularly effective on ferrous metals that are prone to rusting.

Q6: Does laser rust removal affect the metal surface?

A6: Laser rust removal is designed to be non-invasive and typically does not damage the underlying metal. The laser’s precision allows it to remove rust without altering the metal’s surface properties.

Q7: What are the advantages of laser rust removal over traditional methods?

A7: Advantages include higher precision, faster cleaning times, no need for chemicals or abrasives, reduced waste, and minimal damage to the underlying metal.

Q8: How much does laser rust removal cost?

A8: The cost varies based on factors such as the size of the area being cleaned, the extent of rust, and the type of laser system used. Generally, it ranges from a few hundred to several thousand dollars per job.

Q9: Can laser rust removal be used for large-scale industrial applications?

A9: Yes, laser rust removal is suitable for large-scale industrial applications. High-power laser systems can handle extensive rust removal tasks efficiently.

Q10: Is laser rust removal environmentally friendly?

A10: Laser rust removal is environmentally friendly as it does not use harmful chemicals and produces minimal waste. The process mainly involves the removal of rust particles, which can be safely collected and disposed of.

12.2 Tips for Effective Rust Removal with Laser Technology

- Select the Right Laser System

– Power Level: Choose a laser system with appropriate power for the extent of rust removal required. Higher power lasers are suitable for heavy-duty industrial applications, while lower power lasers work well for precision tasks.

– Wavelength: Ensure the laser wavelength is suitable for the material being cleaned. Fiber lasers are versatile and commonly used for rust removal.

- Optimize Laser Parameters

– Beam Focus: Adjust the beam focus to target the rust effectively without damaging the underlying material.

– Pulse Duration: Use shorter pulse durations for precise rust removal and to prevent heat damage to the metal.

– Scanning Speed: Optimize the scanning speed to balance cleaning efficiency and surface protection.

- Prepare the Work Area

– Clean Surface: Remove loose debris and contaminants from the surface before laser cleaning to improve efficiency.

– Ventilation: Ensure proper ventilation to remove vaporized rust particles and prevent accumulation in the workspace.

- Safety Precautions

– Protective Gear: Wear appropriate protective gear, including safety goggles and gloves, to protect against laser exposure and debris.

– Training: Ensure operators are properly trained in laser safety and operation to prevent accidents.

- Regular Maintenance

– Equipment Check: Regularly inspect and maintain the laser equipment to ensure optimal performance and longevity.

– Lens Cleaning: Keep the laser lens clean and free from contaminants to maintain beam quality.

- Test and Adjust

– Test Area: Perform a test on a small, inconspicuous area to determine the best laser settings for the specific rust and material type.

– Adjust Parameters: Fine-tune the laser parameters based on test results to achieve the best cleaning results.

12.3 Summary

Laser rust removal is a precise, efficient, and environmentally friendly method for cleaning metal surfaces. Understanding the technology, choosing the right equipment, and following best practices can help you achieve optimal results. Whether for industrial applications or smaller restoration projects, laser rust removal offers significant advantages over traditional methods, making it a valuable tool in modern maintenance and cleaning processes.