Have you ever seen a rusty old object become shiny and like-new again? This is all thanks to laser rust removal technology – an improved version of traditional cleaning methods such as sandblasting and chemical treatments. Laser rust removal offers precise results and faster removal speed, it helps protect the environment by preserving the integrity of metal surfaces.

In this article, we’ll cover just how remarkable light-based rust-removing techniques can be! So let’s dive into discovering more about laser cleaning technology for restoring metal pieces back to their former glory: its science, advantages compared with other options out there on the market, and extensive applications in various industries – proving that when it comes to effective corrosion elimination, nothing beats powerful lasers!

Short Summary

Laser rust removal is an advanced technique, which uses a laser beam to efficiently remove rust and other contaminants from metal surfaces.

It offers precise, easy-to-operate solutions with minimal training, as well as eco-friendly benefits and improved surface quality.

Cost considerations should be taken into account when selecting the right laser cleaning systems for a project. It can provide long-term savings with reduced labor costs, lower maintenance requirements & increased efficiency.

1. Knowledge of Laser Rust Removal

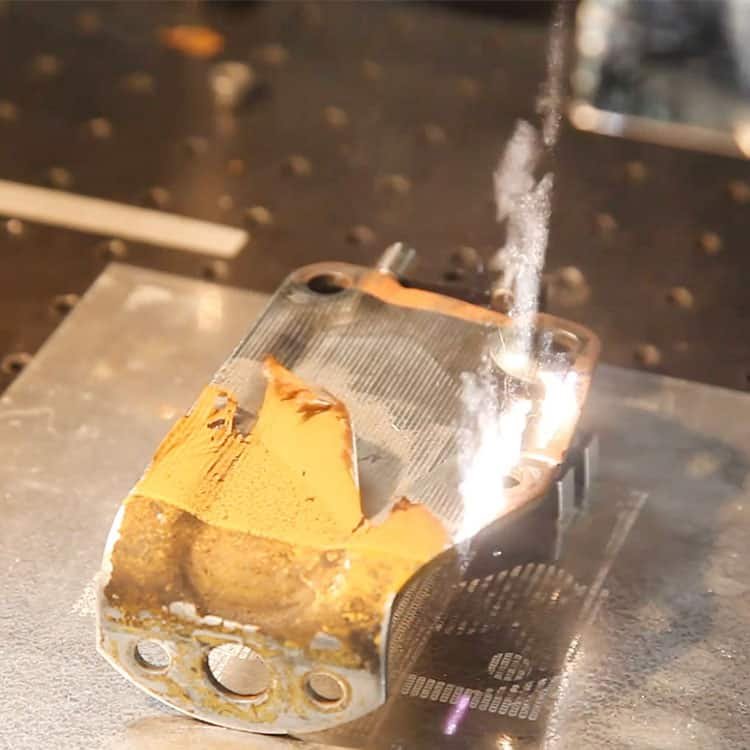

The new laser rust removal technology utilizes laser cleaning systems to quickly and precisely remove all traces of rust, as well as other contaminants from metal surfaces without causing damage. This eco-friendly solution has been adopted for use in a variety of industries, including machine parts, car restoration, equipment upkeep, and restoration projects on historical artifacts, even in production lines. Let’s take a look at how this works!

Laser light is used to vaporize the layer of contamination sitting atop the material below, which allows it to be completely removed while still leaving intact any undamaged underlying material. Compared with traditional methods which is employed for removing rust and corroded matter, laser cleaning machines bring an unparalleled level of precision that requires accuracy rather than bulk work capacity.

1.1 The Science Behind Laser Rust Removal

The technique of laser rust removal is based on the process known as ablation, in which a pulsed laser beam carefully removes material from a surface. The key to this method lies in determining the exact amount of energy required for successful removal (ablation threshold), and also making sure that nothing else beneath it gets damaged or affected.

For more efficient surface cleaning results, shorter pulses are utilized while avoiding excessive heating up of underlying materials. Through laser cleaning systems advanced technology, such high-powered lasers can get rid of thin layers at an amazing rate – approximately 50 cm2/sec!

1.2 Types of Lasers Used in Rust Removal

The process of rust removal can be tailored to the individual needs of a project by selecting the right type of laser. Pulsed lasers are good for all surfaces with pulsed beams, while CW lasers have high-power capabilities and are suitable for removing larger amounts of rust. Whatever choice you make will determine how successful your rust removal job turns out to be.

2 Advantages of Laser Rust Removal

The advantages of laser rust removal are multiple compared to conventional techniques. Its preciseness, ease of use, eco-friendly nature, and consumable free make it an ideal choice for a range of industries and operations. Its improved surface quality with cost efficiency, as well as adaptability, render this method even more desirable across various domains.

2.1 Precise and Easy to Operate

Laser rust removal systems offer a highly accurate and easy-to-use approach to erasing corrosion without damaging the underlying substance. The high level of precision and pulsed energy makes it an ideal choice for intricate projects, which require a clean, polished surface with minimal risk of destruction to the base material, like project car, steel, and aluminum metal products.

When removing rust, businesses are always looking for cost-effective solutions, laser cleaning systems can be considered as their brief training, it’s able to achieve professional results quickly and efficiently, making the laser cleaning process extremely appealing overall.

2.2 Eco-friendly Solution

The laser cleaning process is an environmentally friendly rust removal process. It offers a much better alternative than sandblasting or chemical product treatments, as there is no hazardous waste produced nor any toxic emissions generated during the surface cleansing procedure. As such, laser rust elimination has become more popular for those desiring to reduce their ecological footprint.

2.3 High Efficient

Laser rust removal systems provide a superior solution for removing rust and other contaminants from metal surfaces. They use powerful pulsed laser beams which enable a faster speed of rust elimination compared to traditional methods, resulting in increased productivity overall.

Laser cleaning technology is an ideal choice when it comes to efficiency. With higher-powered laser beam energy, the rate of rust removal increases drastically and allows for project completion much more quickly than normal processes, reaping all kinds of benefits along the way!

2.4 Cost-effective

The initial expenditure on a laser-based rust removal system may exceed that of conventional systems. The long-term cost savings are substantial! Laser cleaning technology is more effective in its cleaning application, which leads to lower labor costs and less demand for cleaning agents or chemicals, consumable free.

So by investing in laser cleaning machines, business owners can anticipate considerable benefits as well as an excellent return on investment over time.

2.5 Versatile

Laser rust removal technology is incredibly versatile, being applicable to a multitude of industries from automotive to aerospace and marine, and also popular in cleaning pipes. This advanced laser cleaning process can eliminate numerous surface contaminants including paint, grease, oxide, welding seam, and the targeted rust.

The adaptability of laser rust elimination allows businesses to benefit in more than one way, by using it for various purposes and thus improving their efficiency with streamlined processes.

2.6 Improved Surface Quality

The use of laser rust removal eliminates the possibility of damage to the underlying material, unlike traditional methods such as sandblasting and chemical treatment. This laser ablation process leaves a pristine metal surface that is smooth and without any quality loss.

The non-destructive laser systems have advantages over chemicals and blasting cleaning. It prevents Waste production while ensuring improved adherence with coating applications, due to its enhanced overall surface finish obtained via laser rust removal technology.

3 Comparing Laser Rust Removal with Traditional Methods

Comparing laser rust removal to two of the most common traditional methods (sandblasting and chemical treatments) is essential, in order for one to make an educated choice as far as which approach works best. It’s clear that there are a number of advantages to using laser cleaning over other types of solutions.

Let us take a look at exactly what makes laser rust removal stand out from these more classic approaches, so you can get the ideal solution tailored specifically for your needs regarding how you want that pesky corrosion treated!

3.1 Sandblasting vs. Laser Rust Removal

For delicate or intricate projects, laser rust removal is a more suitable method of removing corrosion than sandblasting. This non-contact laser cleaning uses focused light to achieve an accurate and smooth surface finish that won’t damage the underlying material, unlike with abrasive particles used in sandblasting, or hazardous chemicals.

Laser cleaning systems provide much less aggressive results without generating additional waste products on sensitive surfaces. At the same time, the laser removes rust technology does not require training, is safe and simple to operate, greatly saves manpower and preparation time, and is maintenance-free and consumable.

3.2 Chemical Treatments vs. Laser Rust Removal

Laser rust removal provides an environmentally friendly and precise solution for eliminating rust, making it a desirable choice when businesses want to maintain cleanliness while being conscious of their environmental impact. It is non-hazardous and environmentally friendly. Chemical treatments are known for potentially posing risks both to operators and the environment.

Another difference is that for different materials and applications, chemical cleaning requires a lot of solutions, and there are many factors to consider. Laser cleaning technology can clean almost all surfaces at the same time, whether it is aluminum or steel metal products, wood or stone surfaces, or large surface areas of paint and rust.

4 Choosing the Right Laser Rust Removal System

When selecting a laser rust removal system, one must take into account various factors such as power requirements, size, and portability. By doing this you can pick the ideal laser cleaning system for your particular application, which provides maximum advantages of utilizing laser technology to eliminate rust.

Taking these points into consideration will guarantee successful results while ensuring it suits all your needs precisely. Thus making sure every benefit from using lasers is received when eliminating any traces of unwanted corrosion on metal surfaces or parts.

You can check more details at Chihalo Laser.

4.1 Power Requirements

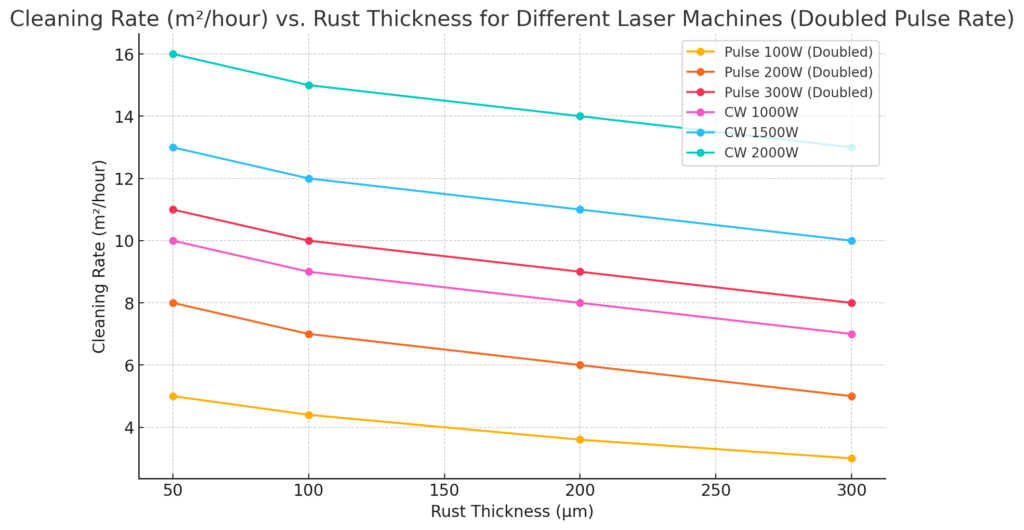

When selecting a laser rust removal system, it is important to determine the power needs of your project. Larger systems that produce high wattage will offer more efficiency and energy, which is better for serious laser cleaning projects, while lower-power lasers can handle less intense tasks with great care.

Below is a list of laser rust removal efficiency charts for your reference:

Basically for the same type of laser, the higher the power, the more expensive it is. Moreover, when the power exceeds a certain range, the cleaning efficiency does not change linearly with the increase of power.

For any rust removal job, making sure you choose a device capable of meeting its demands is key in order to get desirable outcomes from your laser treatment process.

4.2 Size and Portability

When selecting a laser rust removal system, it is important to consider its size and portability. Stationary systems can offer greater power but may not be as ideal for on-site projects requiring frequent moving of the equipment. Smaller, portable machines could better meet these needs because they provide more flexibility and convenience in limited spaces or with restricted access.

So by taking into account both components – size & mobility – you’ll have the assurance that the most suitable laser rust remover will fit right into your processes providing excellent results specific to what you need to accomplish!

5 Cost Considerations and ROI

When considering the purchase of a laser rust removal system, businesses should take into account both its initial cost and potential savings over time. This can allow them to determine if investing in such a solution is economically advantageous or not.

It’s important for companies to evaluate whether laser cleaning technology offers sufficient benefits that exceed the investment it requires – with regards to removing rust from their products – thus making it an effective and lucrative choice.

5.1 Initial Investment

When evaluating the advantages of laser rust removal, it is important to consider both its investment costs and potential benefits. Depending on a system’s strength and capability, this expenditure can range from tens to hundreds of thousands of dollars.

Rust removal using lasers can result in major savings, due to decreased labor needs, as well as lowered maintenance requirements plus improved efficacy. All these factors should be taken into account when determining if investing in such technology suits one’s specific goals or not. No doubt, laser surface cleaning is a cost-effective solution!

5.2 Long-Term Savings and ROI

Laser rust removal is a cost-effective solution that can help businesses maximize their savings in the long run, thanks to its low labor costs and maintenance needs as well as improved efficiency. To decide if investing in laser cleaning system is right for them, companies should carefully consider the initial outlay versus potential future gains. Investing in laser rust removal could be smart decision making on behalf of any business striving for reduced expenses.

6 Applications of Laser Rust Removal

Laser cleaning technology for rust removal has become a popular option across many industries, such as automotive to aerospace, and marine, also other surface cleaning. This versatile approach can be used on various projects, resulting in fast and accurate results that ensure the treated metal surfaces are more durable.

We will now discuss some of the most widespread applications associated with laser rust removal tools. By employing lasers efficiently, it is possible to completely remove corrosion from all kinds of metal surface while maintaining their highest standards of quality.

6.1 Removal of Rust From Machine Parts and Equipment

Laser rust removal is an efficient and reliable solution for getting rid of corrosion, as well as other contaminants, from machine parts and equipment. The results are a clean and solid surface which can enhance the performance of the machinery to its longevity.

Its accuracy means that it has proven suitable for many different industries, which is seeking to keep their tools running optimally by quickly removing rust or any accompanying impurities from difficult-to-reach areas utilizing laser cleaning technology.

The procedure is both speedy yet effective. Being capable of treating multiple materials like metal effectively – erasing away unwanted debris while still maintaining its original condition with ease thanks to lasers’ remarkable characteristics!

6.2 Cleaning of Pipelines And Storage Tanks

Laser rust removal is a reliable, efficient and non-invasive solution for eliminating corrosion from pipelines and tanks. Laser cleaning technology enables targeted treatment of rusted areas without impacting the substrate material, which makes it ideal for maintaining integrity in such equipment.

Rust can be quickly removed making it an attractive choice over traditional cleaning approaches. Laser rust removal preserves safety as well as ensuring effective functioning of these structures in future use scenarios.

6.3 Removal of Rust From Metal Structures Such As Bridges And Buildings

The efficiency of fiber laser rust removal makes it a great option for removing corrosion from metal structures like buildings and bridges. Non-destructive laser cleaner is extremely precise due to its pulse energy and heat, enabling specific areas to be focused on without harming surrounding material.

Laser rust removal guarantees the preservation of these constructions while keeping them safe from weakening as a result of oxidation.

This form of elimination proves especially useful in maintaining the durability and integrity that are necessary when dealing with metal infrastructure, because its accuracy allows targeted treatments without damaging any other elements around it – saving time, energy, and resources overall!

6.4 Removal of rust from car bodies and parts

Laser rust removal provides an efficient and precise solution in car restoration, for eliminating rust and paint from car bodies, parts or other metallic surfaces. The laser cleaning method ensures a clean finish without any damage to the underlying metal, which can maintain the appearance and performance of vehicles.

Rust build-up, corrosion as well as other contaminants are swiftly removed while preserving its original condition making it ideal for these purposes.

6.5 Restoration of classic cars

Classic car enthusiasts understand the importance of maintaining the original look and condition of their cherished vehicles. Laser rust removal is a gentle yet accurate solution for restoring classic cars, getting rid of corrosion as well as other pollutants without damaging the underlying metal or paint job.

This kind of precision and care is required to keep up with its worthiness and authenticity when it comes to vintage automobiles. Making laser rust eradication an optimal option for those wanting to bring back their rides into perfect shape again.

6.6 Restoration of historical artifacts and monuments

Laser rust removal offers a highly precise and gentle approach for eliminating rust, from historical artifacts and monuments in order to protect their original state. The use of laser cleaning technology makes it possible to keep these objects’ cultural importance intact while still performing effective corrosion-removing measures with care. Thus preserving them for future generations.

6.7 Removal of rust and other contaminants from old buildings and structures

Laser rust removal is an efficient way of eradicating rust and dust from aging buildings and structures without detriment to the material itself. Laser cleaner offers a specific ablation threshold, allowing targeted areas to be addressed while leaving any neighboring surfaces undamaged.

By eliminating unwanted corrosion or oxidation, it guarantees that these constructions will remain reliable for years to come.

Given its effectiveness in removing rust with no harm inflicted on adjacent materials, fiber laser cleaning technology represents a great choice when restoring older architecture by doing away with contamination issues safely as well as efficiently.

6.8 Cleaning and maintenance of ships and boats

Ships and boats are constantly exposed to the punishing marine environment, which can result in rusting and other forms of corrosion. To keep these vessels in top-performance shape while prolonging their life expectancy, laser rust removal is a highly effective option for cleaning purposes.

Through its accuracy coupled with efficiency, laser cleaning system quickly removes all traces of oxidation as well as any undesirable contaminants from unreachable nooks or complex surfaces. Making it an optimal choice when it comes to conserving both the form and function of ships and boats alike.

6.9 Removal of rust from metal surfaces on boats and ships

When it comes to protecting metal surfaces on boats and ships from rust, fiber laser rust removal is an efficient answer. This laser cleaner can precisely target corroded areas without affecting the surrounding material. Thus, allowing for a clean finish that ensures better appearance and performance of the vessel in question.

Laser cleaning technology makes removing rusty spots quicker than traditional methods and guarantees accuracy, when pinpointing specific sections with corrosion issues, making sure only those affected parts are treated and leaving all else intact at the same time. That way individuals get optimum results while safeguarding their boat’s or ship’s integrity fully using this state-of-the-art technique called ‘laser rust removal’.

6.10 Cleaning and maintenance of aircraft engines and parts

When it comes to cleaning aircraft engines and parts, laser rust removal provides an effective and accurate solution. By using a powerful laser beam, laser cleaning systems can precisely eradicate rust without causing any harm to the substrate material.

This fiber laser cleaning equipment is quick at getting rid of debris from hard-to-reach spots while remaining economical for the task in hand. Making it an ideal choice when maintaining performance or safety concerns related to those components.

Laser rust removal has proven its efficiency over time with regard to removing corrosion from these pieces, offering a cost-efficient and environment-friendly answer every step along the way!

6.11 Removal of rust from aircraft surfaces

Laser rust removal is a great solution for safely and efficiently eliminating rust from aircraft surfaces, preserving their structural integrity without damaging the surrounding and substrate material. Laser cleaner offers precision targeting of specific areas at fast speeds with cost-effectiveness.

Laser rust removal enables successful maintenance of these components while protecting against corrosion over time. It is an ideal choice given its ability to remove even the most stubborn form of oxidation, which could potentially compromise safety in flight conditions otherwise left unchecked.

7 Summary

Laser rust removal is proving to be a vastly more efficient and environmentally friendly method than traditional rust removal techniques. With its precision, environmental friendliness, cost-effectiveness, and versatility, it is ideal for the environment. To the improved quality of surfaces, it works on.

Laser cleaning technology for removing corrosion has become an increasingly desirable choice for many sectors due to these numerous advantages. Companies should always ensure that they choose a system that meets their particular power requirements as well as size portability needs so that all the benefits can be obtained from this revolutionary cleaning process.

8 F.A.Q.

CHIHALO LASER

Why is laser rust removal so expensive?

Laser rust removal systems, though expensive due to their high technological complexity in manufacturing and design processes, provide a number of benefits that make it worthwhile. Precision is much higher than with MIG welders when performing the task of removing rust from surfaces. Making them well worth their cost compared to less sophisticated items such as cars or welders.

By opting for laser cleaning technology over traditional methods, there is an enhanced capacity regarding corrosion abatement operations not provided by other means available on today’s market.

Do laser rust removers really work?

Laser rust removal is becoming a highly viable option for effectively treating metal surfaces with oxides such as rust. This method has risen in popularity due to its quick, safe, and environmentally friendly characteristics. Laser cleaning technology presents an effective solution that can be applied to metals without any risks or environmental impact.

Rust removal by laser is secure when handled correctly, and Chihalo laser – a pro provider of such solutions – can give safety education to operators. This guarantees that everybody keeps safe while working and follows environmental regulations efficiently.

How does laser cleaning machine work?

Laser cleaning is a process that utilizes high-energy pulses to remove contaminants, such as oil, oxides and paint, from metal surfaces like steel, welding seam and other materials. The energy and heat absorbed by the metals causes these materials to reach their ablation threshold, which then allows them to be ejected during this procedure.

This can help in preparing metal components for bonding or welding joining processes, and it serves well when needing removal of coatings on dies and an overall clean up of any material surface it touches with its laser beam.

What are the benefits of laser rust removal compared to traditional methods?

Laser rust removal is an attractive alternative to traditional methods due to its precision, ease of use and environmental-friendliness. It offers improved surface quality as well as being efficient, cost-effective and versatile. With laser cleaning technology, the process of removing rust can be done quickly while still providing accurate results with no negative impact on the environment or wallet!

Laser rust treatment provides a precise way of dealing with corrosion without sacrificing effectiveness in terms of time savings, material usage or level of work required for success compared with other forms such as manual labour involving metal scraping away from affected areas.