What is Laser Marking?

Laser marking is a technology that uses laser beams to mark or engrave a variety of materials. It is widely employed in industrial applications for the permanent marking of products. The process involves using a laser to remove or alter a material’s surface, creating a visible mark.

In the realm of industrial advancements, laser marking has emerged as a transformative technology, revolutionizing the way products are labeled, tracked, and identified. This cutting-edge technique has become an indispensable tool for various industries, offering unparalleled precision, efficiency, and versatility.

Laser marking is a non-contact method of labeling objects using a laser beam to create marks on the surface. This process involves the removal or alteration of material, resulting in high-quality, permanent markings. The technology is widely employed across diverse sectors, including manufacturing, automotive, aerospace, and electronics.

HIGH PRECISION

High level of detail and accuracy

NON-CONTACT

No physical contact with the material

Permanence

Markings are resistant to wear and environmental factors

Versatility

Suitable for various materials and applications

Why Choose Laser Marking Machine?

9 Reasons That You Can't Reject

1

Respetuoso con el medio ambiente

No chemicals or consumables are used during or after marking, which complies with environmental regulations.

2

Permanent Mark

One-time marking, eternal mark

3

Time-saving

Strong Laser power can engrave a depth metal and material in just seconds, and marking speed is more than 12000mm/s

4

User Friendly

With 5 minutes of training, then can work as an expert!

5

Versatility

One machine can mark different shapes or words on various surface

6

Maintenance Free

Apart from keeping the equipment clean, little to no maintenance is required

7

Long Service Life

Durable and designed for long-term use. The laser source’s life-time is 100,000 hours.

8

Bulk Marking

Ideal for high-volume production and requires no maintenance between parts

9

Automated Marking

It can realize fully automatic or semi-automatic operation, realizing the real 4.0 industry

How does Chihalo Solve?

5 Common Issues of Laser Marking

Material Compatibility Issues

Chihalo Solution

Issue: Certain materials may not respond well to laser marking.

Solution: Test and choose materials compatible with laser marking. Explore additives for better absorption.

Alignment Problems

Chihalo Solution

Issue: Misalignment of the laser beam or bad repeatation precision lead to inaccurate markings.

Solution: Adopt high speed digital golvanometer to achieve excellent precision, Regularly check and calibrate the laser alignment. Ensure stable working conditions.

Slow Marking Speeds

Chihalo Solution

Issue: Marking process takes longer than expected.

Solution: Optimize laser power and upgrade scanning systems for faster marking.

Burn Marks or Material Damage

Chihalo Solution

Issue: Excessive heat during marking causes burning or damage to the material.

Solution: Optimize laser source and suggest you a suitable parameter to mark. Implement effective cooling systems for sustained operations.

Limited Marking Depth Control

Chihalo Solution

Issue: Inability to achieve the desired depth in markings.

Solution: 3D Scanning Camera to confirm the depth.

Contact us for a Free Demo!

Which Laser Marker is Best Suitable For You?

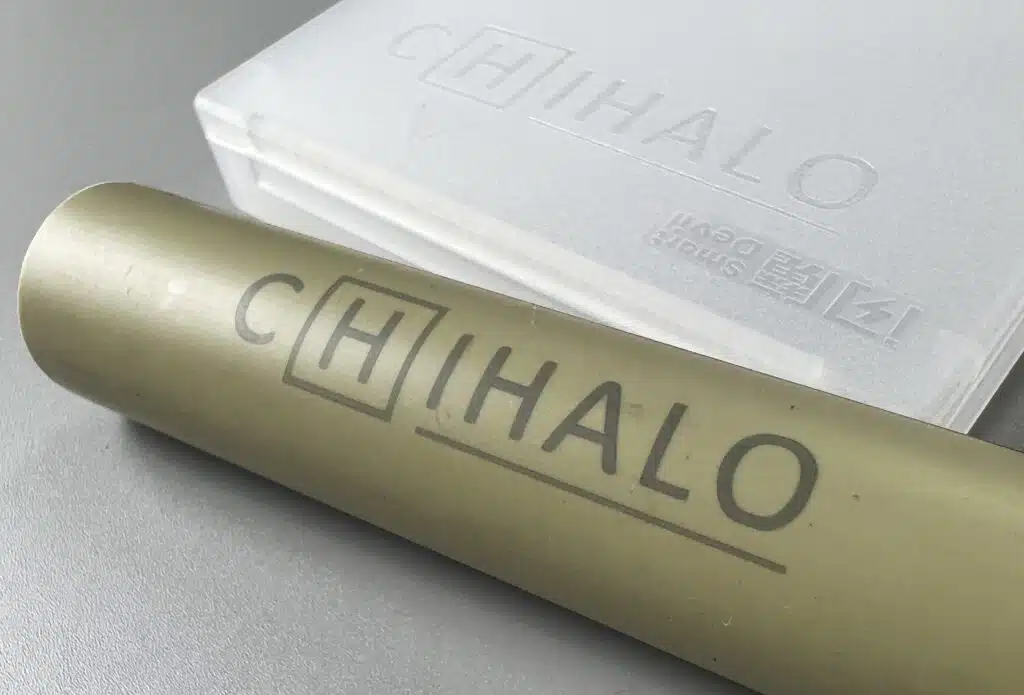

Máquinas de marcado por láser

4 Models of Laser Marker in Chihalo

Fiber Laser Marking Machine

- Portable Fiber Laser Marker

- Desktop Portable Laser Marker

- Cabinet Type Laser Marker

- Online Fiber Laser Marker

UV Laser Marking Machine

- Portable UV Laser Marker

- Desktop UV Laser Marker

- Enclosed UV Laser Marker

- Online UV Laser Marker

Industrial Laser Marking Applications & Videos

Our laser marking machines can mark on various materials like metal and stone, plastic and glass, and so on. It can be portable use, desktop use, or installed on your production line, which is very flexible. Take your project to new heights with our transformative surface-marking solution.

Metal Laser Marking

Try using laser rust removal technology to get rid of rust on your surfaces. It’s faster and more precise than manual labor, making rust disappear effortlessly. You’ll see exceptional efficiency as the laser technology brings your surface back to its original condition, saving you time and money. Laser rust removal is revolutionary and works better than traditional methods.

Wooden Laser Marking

Laser paint removal is a great way to get rid of paint quickly and accurately. You won’t have to struggle with hard scraping or sanding work anymore. Using a laser is a cleaner and safer process that saves time. You’ll be amazed at how easily it removes layers of paint and reveals the beauty underneath.

Leather Laser Marking

Get rid of oxide with laser cleaning machines. Traditional abrasive methods can go away now since laser technology can completely erase oxide layers. You will see how precise, fast, and non-contact the process is. Moreover, you will achieve better cleaning results without wasting resources and harming surfaces. This is revolutionary, efficient, and eco-friendly cleaning.

PVC Pipe Laser Marking

With laser oil removal, you can easily get rid of oil stains on different surfaces without the need for messy and time-consuming cleanup methods. Laser technology is fast, precise, and effective. It guarantees a clean and oil-free environment. By choosing laser oil removal, you are choosing a highly efficient and effortless method of removing oil stains.

Stone Laser Engraving

With laser oil removal, you can easily get rid of oil stains on different surfaces without the need for messy and time-consuming cleanup methods. Laser technology is fast, precise, and effective. It guarantees a clean and oil-free environment. By choosing laser oil removal, you are choosing a highly efficient and effortless method of removing oil stains.

Plastic Laser Marking

With laser oil removal, you can easily get rid of oil stains on different surfaces without the need for messy and time-consuming cleanup methods. Laser technology is fast, precise, and effective. It guarantees a clean and oil-free environment. By choosing laser oil removal, you are choosing a highly efficient and effortless method of removing oil stains.

Common Application References

You don't wanna buy a laser marker?

OK, we also provide marking services for quantities of marking needs!

Why Choose Chihalo Laser Cleaning Machine?

We are a manufacturer of laser marking and cleaning machines, not an assembly plant.

We have independent R&D and customization capabilities to help you update production ability.

We don’t have a B2C e-commerce platform such as Alibaba, and we don’t have professional marketing staff, so you probably haven’t heard of Chihalo. But relying on our own professionalism and 1-to-1 service, in the past 7 years, our laser cleaners have been sold well in Europe and South America.

We hope you can get the most suitable and durable laser marking and cleaning machine here!

The Team

Experienced Technical Team

Jackie Huang

Introducing our esteemed Laser Engineer, Jackie Huang, a pivotal member of Chihalo’s technical team. With a Master’s degree in Optical Engineering and over 8 years of industry experience, Jackie specializes in both laser rust removal and laser marking systems. His academic foundation has been enriched by practical experience, leading to a deep understanding of laser technology from design to deployment. Jackie has a proven track record in delivering customized, high-performance laser solutions that meet and exceed client expectations. His expertise not only covers product development but extends to providing exceptional aftersales service. Choose Chihalo, and benefit from the unparalleled skills and dedication that Jackie brings to every project.

Leo Zhao

Meet Dr. Zhao, one of Chihalo’s leading Laser Experts. Holding a Ph.D. in Optical Engineering, Dr. Zhao brings over a decade of specialized experience in laser rust removal and laser marking technologies. His academic achievements serve as the bedrock for his unparalleled technical acumen, which has been further refined through hands-on leadership in R&D and project management. Dr. Zhao excels in delivering client-focused solutions, ensuring both product quality and customer satisfaction. His comprehensive expertise spans from initial product development to aftersales service, making him an invaluable asset to both Chihalo and our esteemed clients. Trust in his capabilities to deliver innovative, efficient, and safe laser solutions for your business needs.

Our Clients

40 countries, 713 clients

What People Say?

Factory Tour

Welcome to visit us!

- You can see a full range of laser markers here

- You can try to use them and compare their differences

- You can get a fully training and information

5 Steps to Buy a Laser Marking Machine

It's very easy to start!

1 Define Your Requirements Clearly

Tell us the type of material you want to mark, its surface shape and marking areas;

Consider the operating place: portable or desktop or online flying marking, etc.

2 Free Sample Testing if You Nee

Contact us to get a report abou similar application as yours;

Or send us a small sample to do free testing;

It will guild a suitable laser types and powers, which influence the price mostly.

3 Together We Find The Right Cleaner

We will discuss if need any customized solution, like Automated, etc.

We will prepare a proposal for you, within your budget and meet your cleaning requirement.

We will prepare to produce as soon as we receive your order.

4 Package & Shipping

Machines that pass QC quality inspection will enter the packaging process;

All machines are protected by a reusable flight case with foam padding;

We will deliver the machine directly to your door with all formalities.

5 Installation & Training

Turn on the machine, connect the power supply, then can start laser marking;

Our sales engineers will answer your questions online at any time you use the machine;

In Chihalo everything will be very simple and easy!

Contact Us Now!

Maintenance Tips for Laser Marker

The most detailed and comprehensive guide!

- Regularly clean the lenses, mirrors, and other optical components to prevent dust and debris buildup.

- Use a soft, lint-free cloth and specialized optical cleaning solutions for thorough cleaning.

- Be gentle to avoid scratches on sensitive optical surfaces.

- Conduct routine inspections of the entire machine for loose screws, damaged cables, or any signs of wear.

- Address any issues promptly to prevent further damage.

- Check and clean the air assist and exhaust systems to maintain proper ventilation.

- Ensure that the exhaust fan is functioning correctly to remove fumes and particles generated during the marking process.

- Monitor the cooling system, including water or air cooling components.

- Regularly inspect for any leaks, and replace coolant if necessary.

- Keep the cooling system free from contaminants to prevent overheating.

F.A.Q.

Welcome to contact us if you have any related question!

Laser marking machines work by directing a laser beam onto the surface of a material. The laser interacts with the material, causing it to change in appearance through processes like color change, engraving, or surface modification.

Laser marking machines can mark a wide range of materials, including metals, plastics, ceramics, glass, leather, and more. The choice of material depends on the specific laser wavelength and power of the machine.

- Precision: Laser marking provides high precision and intricate detailing.

- Permanent Markings: The markings are durable and resistant to wear.

- Non-Contact Process: Laser marking is a non-contact method, minimizing material damage.

- Versatility: It can handle various materials and applications.

Yes, laser marking is commonly used for product branding. It allows for the application of logos, serial numbers, barcodes, and other identifiers on products, contributing to brand recognition and traceability.

Consider factors such as material type, marking speed, desired marking depth, and precision requirements when choosing a laser marking machine. Consult with experts or the machine supplier for guidance on selecting the most suitable equipment.

Yes, laser marking machines are well-suited for batch production. They offer fast and consistent marking, making them ideal for applications where large quantities of products need to be marked with identical information.

Yes, laser marking machines can adapt to curved or irregular surfaces. Advanced systems may include features like 3D marking capabilities, allowing for precise marking on complex shapes.

The lifespan of a laser marking machine varies depending on usage, maintenance, and quality. Well-maintained machines can last for several years, providing consistent performance.

Yes, laser marking machines are often designed for integration into production lines. They can be synchronized with other equipment for seamless and automated marking in industrial processes.

Related Blogs

Everything you need to know about laser marking machines

Ready to Work Together?

Your email information will be kept strictly confidential, and our lawyers will ensure that your private information is absolutely safe!

If you need help finding the right industrial laser solution for you, we’re here to help!

Please tell us what kind of help you need, we will contact you immediately to provide you with the information you need to help you choose the most suitable solution for you!

Contact us today to start adopting better laser equipment to maximize your benefits and reduce your risks!