Fiber Laser Marking Machine

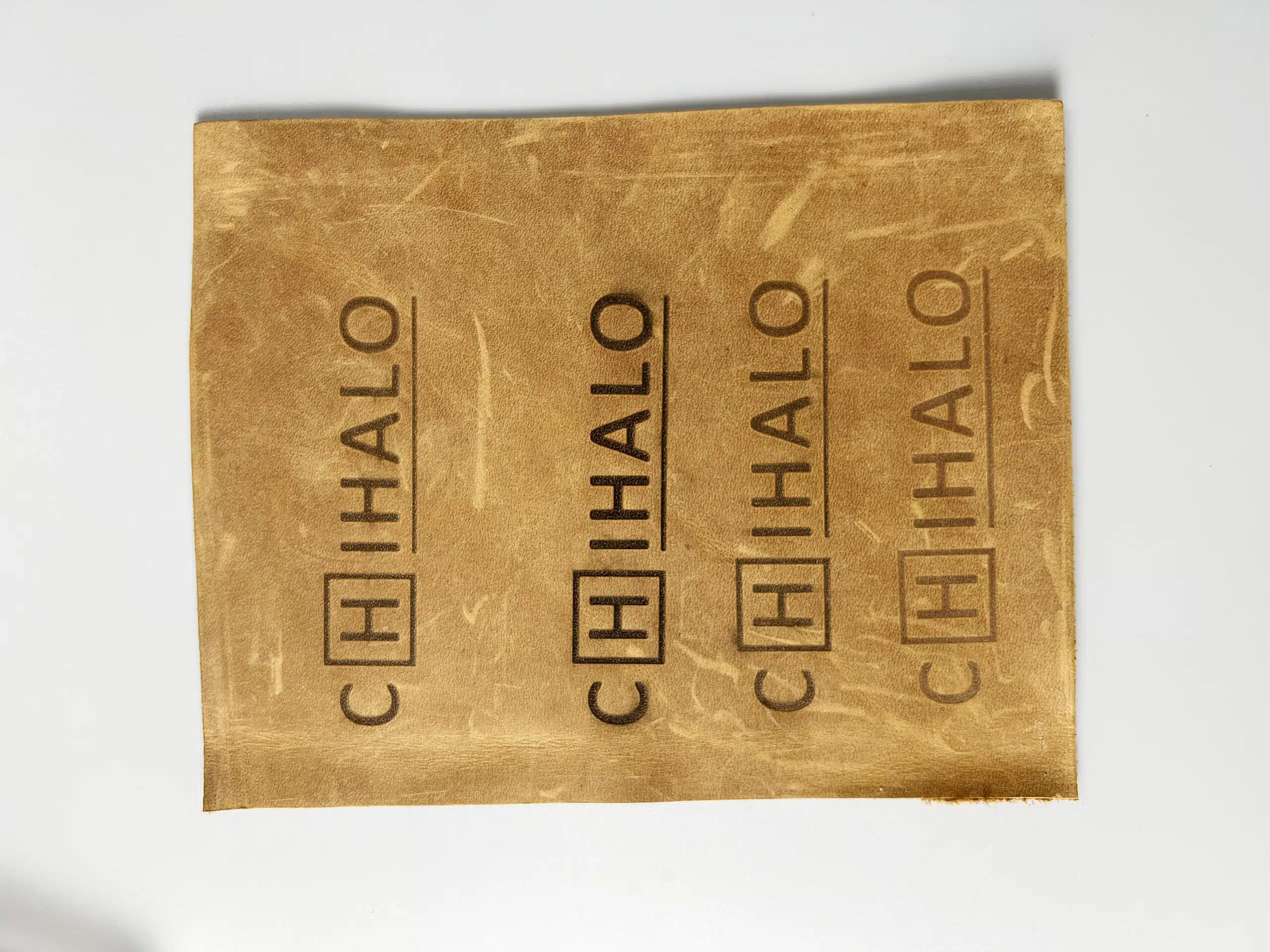

Our laser marking technology can revolutionize your industrial marking procedures.

Achieve accurate and durable results on all types of materials, with the ability to customize branding and intricate designs in seconds.

Our experts offer tailored solutions to enhance manufacturing efficiency and innovation for your unique business needs.

Contact us today to transform your industrial marking operations with unparalleled precision and efficiency!

Parameters of Fiber Laser Marking

| Model | MF-20R | MF-30R | MF-50R | MF-100R |

|---|---|---|---|---|

| Wavelength | 1064nm | 1064nm | 1064nm | 1064nm |

| Laser Power | 20W | 30W | 50W | 100W |

| Fiber Cable | 3m | 3m | 3m | 3m |

| Beam Quality | M²<1.6 | M²<1.6 | M²<1.6 | M²<1.6 |

| Beam Size | 6mm | 6mm | 6mm | 6mm |

| Work-area | 112mm*112mm / 150mm*150mm /300mm*300mm | |||

| Marking Speed | 25000mm/s | 25000mm/s | 25000mm/s | 25000mm/s |

| Minimum Line Width | 10μm | 10μm | 10μm | 10μm |

| Minimum Character | 0.15mm | 0.15mm | 0.15mm | 0.15mm |

| Cooling | Air Cooling | Air Cooling | Air Cooling | Air Cooling |

| Work Temperature | 10-40℃ | 10-40℃ | 10-40℃ | 10-40℃ |

| Storage Temperature | -20℃-50℃ | -20℃-50℃ | -20℃-50℃ | -20℃-50℃ |

| Machine Weight | 100KG | |||

| Machine Size | 60cm*80cm*130cm | |||

| Input Power | 220V 50-60Hz | |||

| Power Consumption | 400W | 500W | 600W | 800W |

| Supported Formats | bmp, jpg, jpeg, gif, tga, png, tif, tiff, ai, plt, dxf, dst, svg, nc, g, gbr | |||

What is Fiber laser marking machine?

Fiber laser marking is a cutting-edge technology used for creating precise and permanent markings on various materials. It utilizes a fiber laser beam to interact with the surface of the material, causing a reaction that results in visible marks. This non-contact process is known for its high precision, allowing for the creation of intricate designs, alphanumeric codes, logos, and more. Fiber laser marking is widely used across industries, including automotive, electronics, medical, and aerospace, due to its versatility in marking materials such as metals (steel, aluminum, copper) and plastics (ABS, PVC). It offers durability, speed, and efficiency in industrial marking applications.

Advantages of Fiber Laser Marking

Permanent Marking

Creates permanent and durable marks on various materials, ensuring longevity and traceability.

High Precision

Achieves extremely precise and detailed markings, suitable for intricate designs and small components.

Versatility in Materials

Marks on a wide range of materials, including metals (steel, aluminum, copper) and plastics (ABS, PVC).

Speed and Efficiency

Enables high-speed marking, enhancing overall production efficiency.

Typic Applications of Fiber Laser Marking

Automotive Component Marking

Fiber laser marking machines are widely used in the automotive industry to mark precise codes, logos, and serial numbers on various components, ensuring traceability and quality control.

Electronics and PCB Marking

In electronics manufacturing, fiber laser marking is applied to mark PCBs (Printed Circuit Boards) with identification codes, specifications, and branding for efficient inventory management.

Medical Device Serialization

Fiber laser marking is employed in the medical sector to serialize and mark medical devices and instruments, meeting stringent regulatory requirements for tracking and authentication.

Take a peek inside our Wonderworld

Fiber Laser Marking

A Fiber Laser Marking Machine is a versatile tool with a wide range of capabilities. Here’s a breakdown of what it can achieve:

ASK FOR A DEMO!

Welcome to contact us for a laser marking solution!

who we are

Why Choose us?

Experience in Industrial Fields

Chihalo's experience extends to serving clients in industrial fields such as restoration of cultural relics, car paint restoration, mold maintenance, and sandblasting, showcasing their competence across diverse sectors.

Technical Expertise:

With a team of 5 R&D engineers, Chihalo boasts technical expertise that translates into innovative and advanced features in their laser marking machines.

Top-Quality Performance

Chihalo ensures cutting-edge technology, providing laser marking machines known for their precision, durability, and high-performance standards.

Customization and Solutions

Chihalo caters to individual needs, offering customization in design and solutions, ensuring that the laser marking machine aligns perfectly with specific business requirements.

Professional and Timely Service

Chihalo prides itself on offering one-to-one professional and timely service, providing comprehensive support throughout the customer's journey.

Our Team

Jackie Huang

Production Manager

Introducing our esteemed Laser Engineer, Jackie Huang, a pivotal member of Chihalo’s technical team. With a Master’s degree in Optical Engineering and over 8 years of industry experience, Jackie specializes in both laser rust removal and laser marking systems. His academic foundation has been enriched by practical experience, leading to a deep understanding of laser technology from design to deployment. Jackie has a proven track record in delivering customized, high-performance laser solutions that meet and exceed client expectations. His expertise not only covers product development but extends to providing exceptional aftersales service. Choose Chihalo, and benefit from the unparalleled skills and dedication that Jackie brings to every project.

Leo Zhao

Expert of Laser

Meet Dr. Zhao, one of Chihalo’s leading Laser Experts. Holding a Ph.D. in Optical Engineering, Dr. Zhao brings over a decade of specialized experience in laser rust removal and laser marking technologies. His academic achievements serve as the bedrock for his unparalleled technical acumen, which has been further refined through hands-on leadership in R&D and project management. Dr. Zhao excels in delivering client-focused solutions, ensuring both product quality and customer satisfaction. His comprehensive expertise spans from initial product development to aftersales service, making him an invaluable asset to both Chihalo and our esteemed clients. Trust in his capabilities to deliver innovative, efficient, and safe laser solutions for your business needs.

About Chihalo Factory

Founded in 2016, Chihalo is a preeminent OEM and B2B manufacturer specializing in laser cleaning and marking machines.

With a specialized team of R&D and sales engineers, we are at the cutting edge of laser cleaning technological innovation.

Our global reach extends predominantly to Europe and Latin America, serving a diverse clientele that values quality and customization.

We operate under a dual business model, catering to both B2C and B2B clients with one-to-one professional service.

Our commitment to quality assurance is unwavering, ensuring that each laser equipment meets the industry’s highest standards. Choose Chihalo for a reliable, long-term partnership that offers you a distinct competitive edge.

Our gallery

Factory Tour

Welcome to visit our factory! We are delighted to show you our state-of-the-art facilities, cutting-edge technology, and skilled workforce. Explore our production processes, witness our commitment to quality, and experience firsthand the passion that drives our team. Feel free to ask questions and discover why our factory is a leader in the industry.

Customers reviews

What people say

Frequently Asked Questions

Welcome to contact us if you have any question!

About Fiber Laser Marking

A fiber laser marking machine is a precision tool that utilizes fiber laser technology to create permanent marks on a variety of materials. It is known for its efficiency, versatility, and high-quality marking capabilities.

Fiber laser marking machines can mark a wide range of materials, including metals (steel, aluminum, brass), plastics, ceramics, rubber, and some types of coated materials.

Yes, fiber laser marking machines are capable of deep engraving, making them suitable for applications where a more pronounced mark or engraving depth is required.

Fiber laser marking machines primarily create monochrome marks. While color variations are limited, certain techniques and materials may allow for color effects on specific surfaces.

Yes, fiber laser marking machines can mark on curved or irregular surfaces. Advanced models with 3D marking capabilities ensure precision on three-dimensional objects.

About Purchasing Laser Marker

When selecting a fiber laser marker, it’s crucial to focus on power options, wavelength, marking speed, and the machine’s overall durability. These factors directly impact the efficiency and longevity of your marking processes.

The power of a fiber laser marker determines its marking depth and speed. Higher power options are suitable for deep engraving on materials like metals, while lower power is ideal for delicate marking on surfaces such as plastics. Consider the specific requirements of your applications before deciding on the power level.

Yes, fiber laser markers are versatile and can mark various materials, including metals, plastics, ceramics, and more. Ensure that the chosen machine provides the necessary wavelength and power for the specific materials you intend to mark.

To guarantee high-quality markings, consider factors such as focus control, beam quality, and the cleanliness of the marking environment. Regular maintenance and calibration also play a crucial role in sustaining optimal performance and ensuring consistent, clear markings.

When investing in a fiber laser marker, inquire about the manufacturer’s warranty, technical support, and available training resources. A reliable warranty ensures protection against potential issues, while comprehensive support and training contribute to the successful integration and operation of the equipment.