CW Laser Cleaning Machine

- Portable and Compact Design

- Water Cooling, Suitable for Outdoor Use

- Dual-axis Cleaning Head and Software

What is CW Laser Cleaning Machines?

A CW laser cleaner is a device that uses Continuous Wave (CW) laser technology for cleaning.

Unlike a pulsed laser cleaner, a CW laser cleaner emits a laser beam continuously rather than intermittently in pulses.

Currently, all powers are water-cooled systems, with the exception of the CW 1500W, which is air-cooled.

We offer 3 options of single-axis, dual-axis and 4-in-1 cleaning heads.

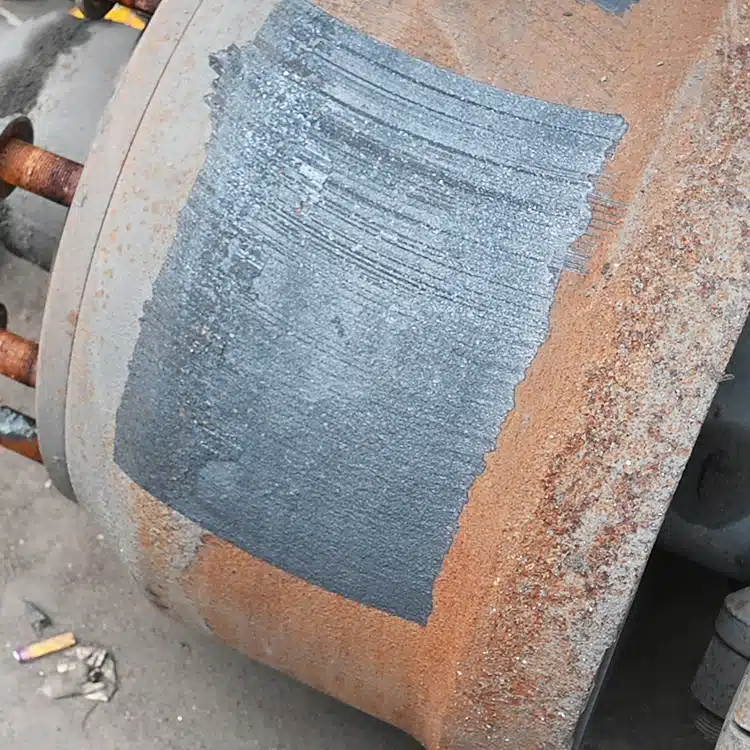

In terms of cleaning results, the CW removes rust and paint quickly and is mainly used for surfaces such as metal and stone.

Exclusive Advantages

Usually, its power range is high, from 1000W to 4000W, and cleaning efficiency is very fast.

-

High Laser Power CW powers from 1000W to 4000W are available.

-

Focused Energy Customized smaller beam size for a much more focused laser power.

-

Fast Efficiency for Paint and Rust High average power, which help to clean rust and paint in a super fast speed.

-

Compact Water-cooled Design Water cooling, Enclosed chassis for better protection for the whole parts.

-

Portable Cleaning Handle 3 kinds of handheld cleaning heads for option. Only 0.8KG weight.

-

10m Long Fiber Cable The long fiber cable allows you to use the machine wherever you want.

Parameters

| Model | CF-1000CW | CF-1500CW | CF-2000CW | CF-3000CW | CF-4000CW |

|---|---|---|---|---|---|

| Wavelength | 1080nm | 1080nm | 1080nm | 1080nm | 1080nm |

| Laser Power | 1000W | 1500W | 2000W | 3000W | 4000W |

| Fiber Cable | 10m | 10m | 10/15m | 10/15m | 10/15m |

| BPP | 0.5-4mm*mrad | 0.5-4mm*mrad | 0.5-4mm*mrad | 0.5-4mm*mrad | 0.5-4mm*mrad |

| Frequency | 10-20KHz | 10-20KHz | 10-20KHz | 10-20KHz | 10-20KHz |

| Work-area | 200mm | 200mm | 200mm | 200mm | 200mm |

| Scan Graphics | Line, Spiral, Rectangle, Circular, Rotating and so on | ||||

| Red Indicator | YES | YES | YES | YES | YES |

| Cooling | Water Cooling | Water Cooling | Water Cooling | Water Cooling | Water Cooling |

| Work Temperature | 10-40℃ | 10-40℃ | 10-40℃ | 10-40℃ | 10-40℃ |

| Storage Temperature | -20℃-50℃ | -20℃-50℃ | -20℃-50℃ | -20℃-50℃ | -20℃-50℃ |

| Optical Weight | 2KG | 2KG | 2KG | 2KG | 2KG |

| Machine Weight | 180KG | 200KG | 230KG | 300KG | 300KG |

| Machine Size | 95cm*60cm*100cm | 95cm*60cm*100cm | 115cm*60cm*100cm | 115cm*60cm*100cm | 115cm*60cm*100cm |

| Input Power | 220V 50-60Hz | 220V 50-60Hz | 220V 50-60Hz | 380V 50-60Hz | 380V 50-60Hz |

| Power Consumption | 4.5KW | 5KW | 11KW | 15KW | 18KW |

Benefit of CW Laser CLeaning Machines

1 Portable and Compact

0.8KG Portable Cleaning head, compact enclosed chassis design, You can Clean Every Thing at Every Place with it.

2 Water Cooling

Water cooling brings a stable working performance, which supports for a longtime non-stop cleaning.

3 Self-designed Dual-axis cleaning head

Set all Parameters on Clean Head, Easier but Safer.

4 Eco-Friendly and Safe Operation

Operate without the Need for Chemicals or Abrasive Materials.

Options for CW Laser Cleaning Machines

1 Laser Configuration

Power range is from 1000W to 3000W. Higher power increases the cleaning efficiency, reducing working time.

2 Air Knife

Installed on the cleaning head to prevent dust from accumulating on the lens by blowing out a continuous stream of clean air. This not only extends lens life, but also speeds up cleaning efficiency.

3 Dust & Fume Extraction

Vacuum devices of various sizes and specifications can be optionally integrated into the cleaning head and are equally portable.

4 Fixed Focus Frame

In 2D cleaning, the focus can be maintained and the cleaning effect is more uniform.

Typical Applications of Backpack Laser CLeaning Machines

1 Graffiti Removal

Power range is from 20W to 300W. Higher power increases the cleaning efficiency, reducing working time.

2 Rust Removal in Remote Locations

These machines can be easily carried to remote or hard-to-reach locations like pipelines, bridges, or offshore platforms for rust removal and surface preparation.

3 Cultural Relic Restoration

The backpack design allows conservators to carefully clean and restore artifacts and historical monuments on-site, without the need for transporting sensitive items.

4 High-Altitude Cleaning Tasks

The lightweight and portable nature of these machines make them suitable for high-altitude tasks like cleaning communication towers, wind turbines, or mountain installations.

Typical Applications

Laser rust removal, laser paint removal, furniture cleaning, kitchenware cleaning, automotive parts maintenance, and more

Laser-Farbentfernung

Laser Coating Removal

Laser Rust Removal

Häufig gestellte Fragen.

CW (Continuous Wave) Laser Cleaning Technology is an advanced method that utilizes a continuous laser beam for surface cleaning. It differs from pulsed laser systems by emitting a constant beam of light, providing a continuous cleaning process. This technology excels in precision and effectiveness, distinguishing it from traditional cleaning methods involving abrasives or chemicals.

CW Laser Cleaning works by directing a continuous laser beam onto a surface, removing contaminants, rust, or unwanted materials through ablation. Its primary applications include:

Manufacturing: Cleaning industrial equipment and machinery.

Restoration: Gentle cleaning of delicate artifacts and cultural relics.

Automotive: Preparing surfaces for painting and removing coatings from vehicles.

CW Laser Cleaning offers several advantages, including:

Precision: The continuous beam allows for highly precise cleaning, suitable for intricate surfaces.

Reduced Heat Generation: Continuous operation minimizes heat build-up, preventing damage to sensitive materials.

Efficiency: Swift cleaning process with minimal downtime, enhancing overall productivity.

CW Laser Cleaning promotes environmental sustainability by:

Chemical-Free Operation: Eliminating the need for chemicals reduces environmental impact.

Reduced Waste: Minimizing waste generation compared to abrasive methods.

Energy Efficiency: The continuous wave design enhances energy efficiency during the cleaning process.

Yes, CW Laser Cleaning Technology is adaptable and can be integrated into existing industrial processes. Its flexibility allows for customization to meet specific cleaning requirements, making it a versatile and efficient solution for various industries.

Contact us to get those free E-books

Send Us A Message