UV Laser Marking Machine

Introducing our UV and Green Laser Marking Machines: Where precision meets versatility in marking technology.

Harnessing the power of UV and green laser beams, these machines offer unparalleled accuracy and flexibility, enabling precise marking on a wide range of materials.

From intricate designs to clear, crisp markings, experience the efficiency and quality of our laser marking solutions.

Ready to elevate your marking processes? Contact us today to explore the endless possibilities with our UV and green laser marking machines.

| Model | MF-UV3 | MF-UV5 | MF-UV10 | MF-Green5 | MF-Green10 |

|---|---|---|---|---|---|

| Wavelength | 355nm | 532nm | |||

| Laser Power | 3W | 5W | 10W | 5W | 10W |

| Fiber Cable | 3m | 3m | |||

| Beam Quality | M²<1.2 | M²<1.3 | |||

| Beam Size | 0.8±0.2mm | 0.8±0.1mm | |||

| Pulse Width | <12ns | <35ns | |||

| Frequency | 10-200kHz | 10-200kHz | |||

| Work-area | 112mm*112mm / 150mm*150mm /300mm*300mm | ||||

| Marking Speed | 25000mm/s | 25000mm/s | 25000mm/s | 25000mm/s | 25000mm/s |

| Minimum Line Width | 10μm | 10μm | 10μm | 10μm | 10μm |

| Minimum Character | 0.15mm | 0.15mm | 0.15mm | 0.15mm | 0.15mm |

| Cooling | Water Cooling | ||||

| Work Temperature | 10-35℃ | ||||

| Storage Temperature | -20℃-65℃ | ||||

| Machine Weight | 150KG | ||||

| Machine Size | 68cm*97cm*140cm | ||||

| Input Power | 220V 50-60Hz | ||||

| Power Consumption | 400W | 600W | 800W | 400W | 800W |

| Supported Formats | bmp, jpg, jpeg, gif, tga, png, tif, tiff, ai, plt, dxf, dst, svg, nc, g, gbr | ||||

What is UV Laser Marking?

CO2 laser marking operates on the principle of using a high-energy beam of light generated by a carbon dioxide (CO2) laser to mark or engrave various materials. The CO2 laser emits infrared light at a wavelength of 10.6 micrometers, which is highly absorbed by organic materials like wood, paper, plastics, and fabrics, as well as by some metals and ceramics.

The process involves directing the focused laser beam onto the surface of the material to be marked. The intense energy of the laser heats and vaporizes the material at the point of contact, creating a permanent mark. This can be achieved through various mechanisms, including ablation (removing material), surface color change, or chemical reaction.

Advantages of UV Laser Marking

High Precision

UV lasers produce a small focal spot size, enabling finer details and high-resolution markings, perfect for applications requiring intricate designs or small text.

Minimal Heat Effect

UV laser marking generates minimal heat-affected zones, reducing the risk of material damage or deformation, especially on heat-sensitive materials like plastics and certain metals.

Wide Material Compatibility

UV lasers can mark a variety of materials, including plastics, glass, ceramics, and certain metals, offering versatility for diverse marking applications.

High Contrast Markings

UV laser marking produces high-contrast markings with excellent readability, enhancing product branding, traceability, and aesthetics.

Fast Processing Speed

UV lasers operate at high speeds, resulting in faster marking cycles and increased production efficiency, ideal for high-volume manufacturing environments.

Non-Contact Process

UV laser marking is a non-contact process, minimizing the risk of contamination or damage to delicate surfaces, ensuring clean and precise markings.

UV Marking Applications

Electronics

Marking semiconductor components, circuit boards, and electronic enclosures with serial numbers, barcodes, and logos for identification and traceability.

Medical Devices

Engraving regulatory information, lot numbers, and expiration dates on medical instruments, implants, and packaging for compliance and safety purposes.

Plastics and Polymers

Marking plastic components, packaging, and consumer products with serial numbers, logos, and barcodes for identification and branding.

Glass and Ceramics

Engraving logos, designs, and text onto glassware, ceramic tiles, and decorative items for customization and branding purposes.

Packaging

Marking packaging materials such as plastic, glass, and cardboard with product information, expiration dates, and barcodes for inventory management and consumer awareness.

Medical and Dental

Marking surgical instruments, dental tools, and medical implants with identification codes, lot numbers, and regulatory information for tracking and quality assurance.

Take a peek inside our Wonderworld

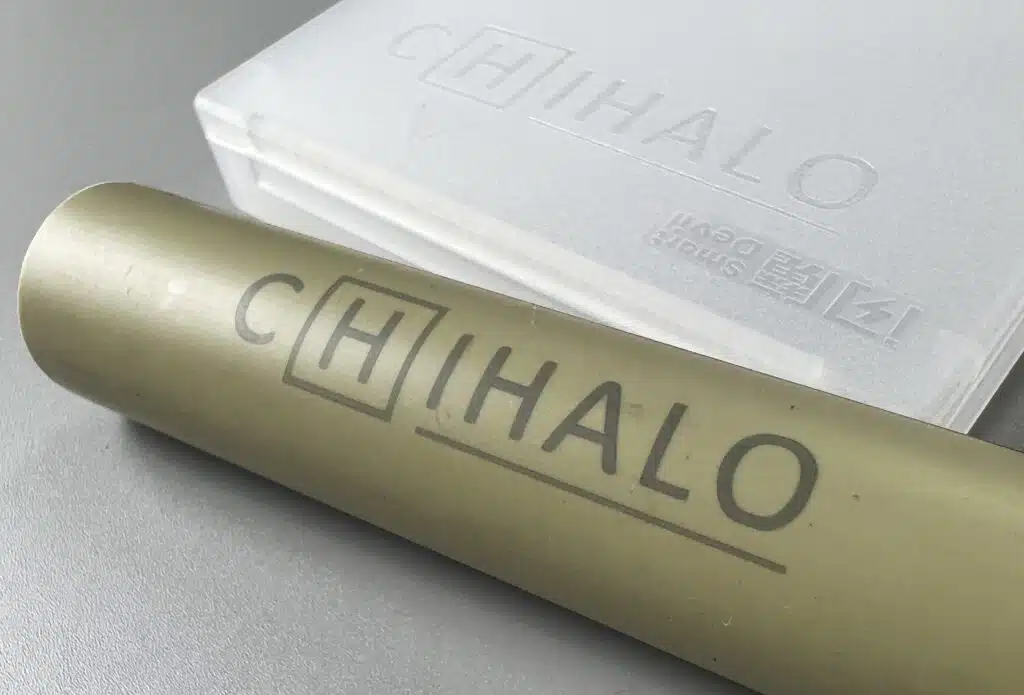

UV Marking Samples

Discover the exceptional precision and versatility of our UV laser marking technology through our curated samples. From intricate designs on delicate plastics to high-contrast markings on tough metals, our samples showcase the unparalleled quality and clarity achievable with UV laser marking. Experience the intricate details, sharp contrasts, and durability of our marks, demonstrating the capability of UV laser technology to meet the most demanding marking requirements. Ready to elevate your marking standards? Contact us today to explore the endless possibilities with UV laser marking.

ASK FOR A DEMO!

Welcome to contact us for a laser marking solution!

who we are

Why Choose us?

Versatility Across Materials

From plastics and glass to metals, Chihalo's UV laser marking machines exhibit versatility, making them suitable for diverse marking applications across a wide range of materials.

Customization Options

Tailor our UV laser marking machines to your specific needs. Chihalo offers customization options to address unique requirements, providing flexibility for various industries.

Unrivaled Precision

Chihalo UV laser marking machines deliver unmatched precision, ensuring intricate details and fine markings, perfect for applications requiring high-resolution results.

High-Speed Performance

Chihalo's UV laser marking machines operate at high speeds, facilitating faster marking cycles and increased production efficiency for time-sensitive applications.

Reliability in Every Mark

Count on the reliability of Chihalo machines for consistent and durable marks, ensuring longevity and readability throughout the product lifecycle.

Our Team

جاكي هوانج

Production Manager

Introducing our esteemed Laser Engineer, Jackie Huang, a pivotal member of Chihalo’s technical team. With a Master’s degree in Optical Engineering and over 8 years of industry experience, Jackie specializes in both laser rust removal and laser marking systems. His academic foundation has been enriched by practical experience, leading to a deep understanding of laser technology from design to deployment. Jackie has a proven track record in delivering customized, high-performance laser solutions that meet and exceed client expectations. His expertise not only covers product development but extends to providing exceptional aftersales service. Choose Chihalo, and benefit from the unparalleled skills and dedication that Jackie brings to every project.

Leo Zhao

Expert of Laser

Meet Dr. Zhao, one of Chihalo’s leading Laser Experts. Holding a Ph.D. in Optical Engineering, Dr. Zhao brings over a decade of specialized experience in laser rust removal and laser marking technologies. His academic achievements serve as the bedrock for his unparalleled technical acumen, which has been further refined through hands-on leadership in R&D and project management. Dr. Zhao excels in delivering client-focused solutions, ensuring both product quality and customer satisfaction. His comprehensive expertise spans from initial product development to aftersales service, making him an invaluable asset to both Chihalo and our esteemed clients. Trust in his capabilities to deliver innovative, efficient, and safe laser solutions for your business needs.

About Chihalo Factory

Founded in 2016, Chihalo is a preeminent OEM and B2B manufacturer specializing in laser cleaning and marking machines.

With a specialized team of R&D and sales engineers, we are at the cutting edge of laser cleaning technological innovation.

Our global reach extends predominantly to Europe and Latin America, serving a diverse clientele that values quality and customization.

We operate under a dual business model, catering to both B2C and B2B clients with one-to-one professional service.

Our commitment to quality assurance is unwavering, ensuring that each laser equipment meets the industry’s highest standards. Choose Chihalo for a reliable, long-term partnership that offers you a distinct competitive edge.

Our gallery

Factory Tour

Welcome to visit our factory! We are delighted to show you our state-of-the-art facilities, cutting-edge technology, and skilled workforce. Explore our production processes, witness our commitment to quality, and experience firsthand the passion that drives our team. Feel free to ask questions and discover why our factory is a leader in the industry.

Customers reviews

What people say

Frequently Asked Questions

A UV laser marking machine is a type of laser marking system that utilizes a ultraviolet (UV) laser to create marks on various materials. It emits a high-energy beam of UV light, which is absorbed by the material’s surface, causing it to undergo a photochemical reaction and produce a permanent mark. UV laser marking is particularly suitable for applications requiring high precision and minimal heat-affected zones.

A UV laser marking machine works by emitting a focused beam of UV light onto the surface of the material to be marked. The UV light interacts with the molecules in the material, causing them to break chemical bonds and create a contrast mark. This process is highly precise and can produce detailed marks with minimal heat generation, making it ideal for sensitive materials such as plastics, glass, and certain metals.

UV laser marking machines offer several advantages, including high precision, minimal heat-affected zones, fast marking speeds, and the ability to mark on a wide range of materials, including plastics, glass, ceramics, and metals. UV marking produces high-quality, permanent marks that are resistant to fading, smudging, and abrasion, making it suitable for applications requiring durability and longevity.

UV laser marking machines can mark a variety of materials, including plastics, glass, ceramics, metals, semiconductors, and certain types of organic materials. The versatility of UV marking makes it suitable for a wide range of applications, including product identification, branding, serialization, and decorative marking in industries such as electronics, medical devices, automotive, and packaging.

When selecting a UV laser marking machine, important factors to consider include laser power, marking speed, marking area size, software capabilities for design and control, cooling system efficiency, maintenance requirements, and the overall build quality of the machine. It’s also essential to evaluate the reputation of the manufacturer and the level of technical support provided.

Yes, UV laser marking machines can be seamlessly integrated into automated production lines to facilitate continuous marking of products without manual intervention. Integration may involve incorporating the laser system with robotics, conveyor systems, or other machinery to enable efficient marking of parts as they move through the production process.

To optimize the performance of a UV laser marking machine, regular maintenance is crucial. This includes cleaning the optics and lenses to ensure optimal beam quality, checking and calibrating the laser system regularly, and monitoring the cooling system to prevent overheating. Additionally, staying updated with software upgrades and implementing best practices for design and setup can help maximize efficiency and quality of marking results.