CO2 Laser Marking Machine

Where precision meets efficiency in industrial innovation. Harnessing cutting-edge CO2 laser technology, this machine offers unparalleled accuracy and speed, elevating your marking processes to new heights.

From intricate designs to clear, crisp markings, experience the power of precision with our CO2 laser marking solution.

Ready to revolutionize your marking game? Contact us today to explore the endless possibilities.

What is CO2 Laser Marking?

CO2 laser marking operates on the principle of using a high-energy beam of light generated by a carbon dioxide (CO2) laser to mark or engrave various materials. The CO2 laser emits infrared light at a wavelength of 10.6 micrometers, which is highly absorbed by organic materials like wood, paper, plastics, and fabrics, as well as by some metals and ceramics.

The process involves directing the focused laser beam onto the surface of the material to be marked. The intense energy of the laser heats and vaporizes the material at the point of contact, creating a permanent mark. This can be achieved through various mechanisms, including ablation (removing material), surface color change, or chemical reaction.

Supporting Subheading

Applications of CO2 Laser Marking

Metals

Stainless steel, aluminum, brass, copper, titanium, and various alloys

Plastics

Acrylic, polycarbonate, ABS, PVC, PET, polyethylene, and polypropylene

Wood

Hardwoods (e.g., oak, maple, walnut) and softwoods (e.g., pine, cedar)

Glass

Borosilicate glass, soda-lime glass, tempered glass, and coated glass

Paper and Cardboard

CO2 lasers can cut, score, or engrave paper and cardboard materials, allowing for the creation of intricate designs, packaging prototypes, and artistic applications.

Leather

CO2 lasers can engrave logos, text, and designs onto leather materials, including genuine leather, suede, and synthetic leather, for personalized products such as wallets, belts, and accessories.

Rubber

Natural rubber, silicone rubber, and synthetic rubber. CO2 lasers can engrave or mark rubber materials with precision, ideal for creating stamps, gaskets, seals, and industrial components.

Textiles

Fabrics, synthetic fibers, and natural fibers. CO2 lasers can cut, engrave, or mark textile materials for fashion, apparel, upholstery, and textile-based products.

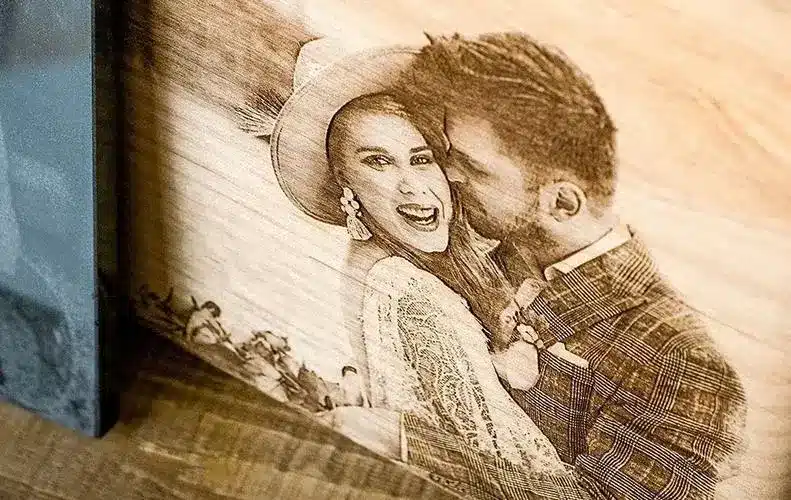

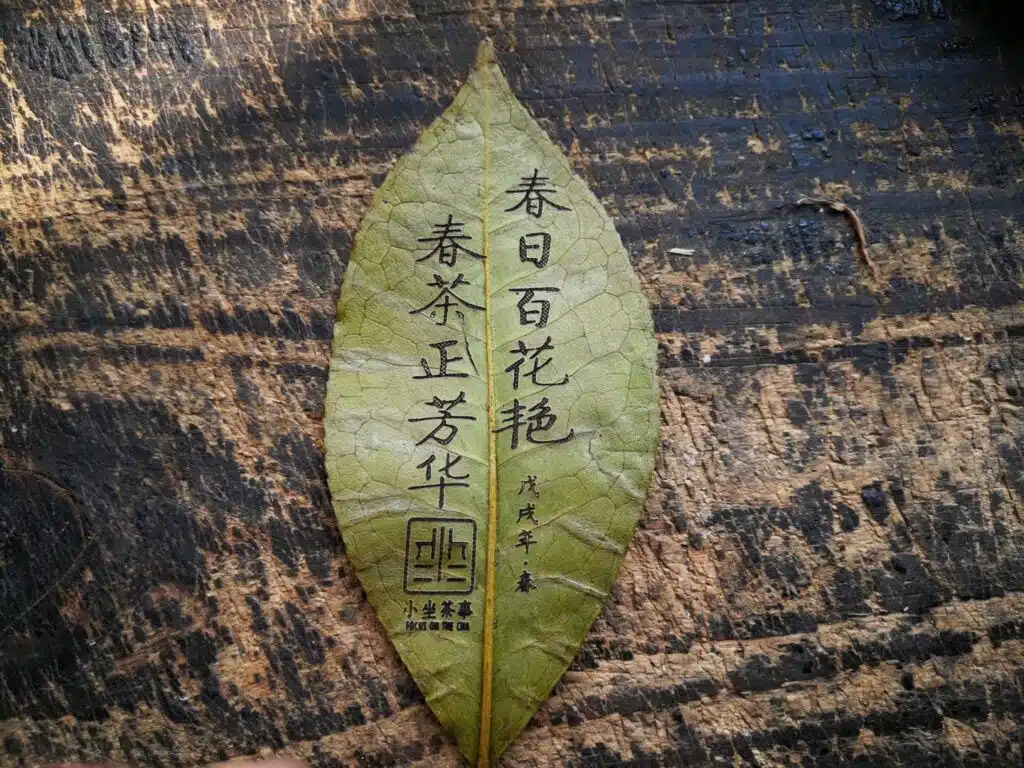

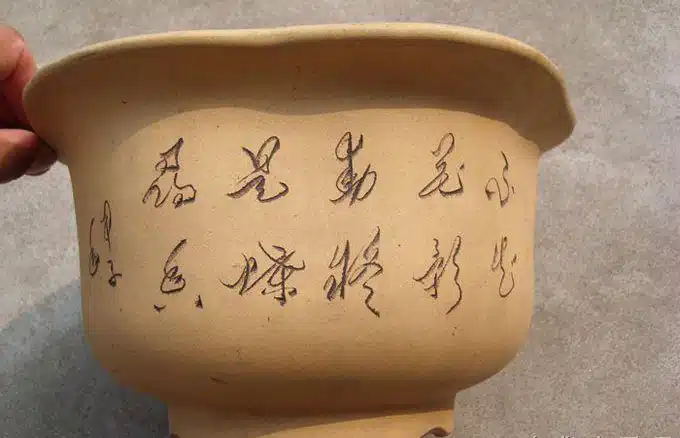

Marking Samples

Explore our gallery of CO2 laser marking samples, showcasing the precision and versatility of our marking solutions.

From crisp text and intricate logos on metal and plastic surfaces to elegant engravings on wood and glass, our samples demonstrate the endless possibilities of CO2 laser marking technology.

Witness the impeccable quality and attention to detail in each mark, illustrating the capability of our machines to meet the diverse marking needs of various industries.

Whether you’re looking for product identification, branding, or personalization, our CO2 laser marking solutions deliver exceptional results every time.

ASK FOR A DEMO!

Welcome to contact us for a laser marking solution!

who we are

Why Choose us?

Timely Service

We prioritize customer satisfaction and strive to provide timely service and support to ensure minimal downtime and maximum productivity for your operations.

Competitive Pricing

While offering top-quality performance and service, we also strive to provide competitive pricing, making our CO2 laser marking machines a cost-effective solution for your marking needs.

Top-Quality Performance

Our CO2 laser marking machines are built with the latest technology and premium components, ensuring consistent and reliable performance for your marking needs.

Versatile Marking Capabilities

From metals and plastics to wood and glass, our machines can mark a wide range of materials with precision and clarity, offering versatility for various applications.

Customization Options

We understand that every marking requirement is unique. That's why we offer customization options to tailor our machines to your specific needs, ensuring optimal results for your projects.

Professional Support

With Chihalo, you're not just purchasing a machine; you're gaining access to our team of dedicated professionals who provide expert guidance and support throughout your journey, from installation to maintenance.

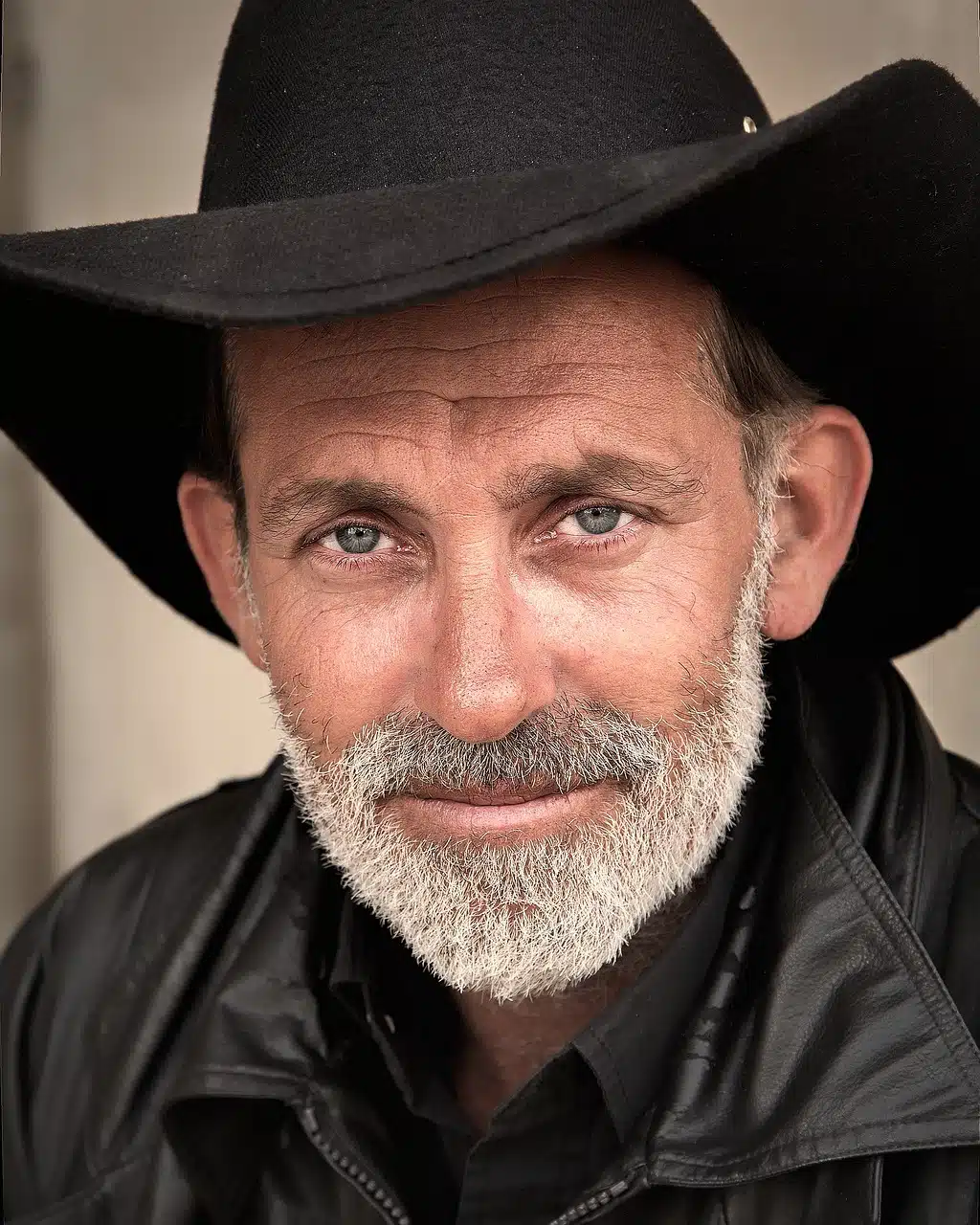

Our Team

جاكي هوانج

Production Manager

Introducing our esteemed Laser Engineer, Jackie Huang, a pivotal member of Chihalo’s technical team. With a Master’s degree in Optical Engineering and over 8 years of industry experience, Jackie specializes in both laser rust removal and laser marking systems. His academic foundation has been enriched by practical experience, leading to a deep understanding of laser technology from design to deployment. Jackie has a proven track record in delivering customized, high-performance laser solutions that meet and exceed client expectations. His expertise not only covers product development but extends to providing exceptional aftersales service. Choose Chihalo, and benefit from the unparalleled skills and dedication that Jackie brings to every project.

Leo Zhao

Expert of Laser

Meet Dr. Zhao, one of Chihalo’s leading Laser Experts. Holding a Ph.D. in Optical Engineering, Dr. Zhao brings over a decade of specialized experience in laser rust removal and laser marking technologies. His academic achievements serve as the bedrock for his unparalleled technical acumen, which has been further refined through hands-on leadership in R&D and project management. Dr. Zhao excels in delivering client-focused solutions, ensuring both product quality and customer satisfaction. His comprehensive expertise spans from initial product development to aftersales service, making him an invaluable asset to both Chihalo and our esteemed clients. Trust in his capabilities to deliver innovative, efficient, and safe laser solutions for your business needs.

About Chihalo Factory

Founded in 2016, Chihalo is a preeminent OEM and B2B manufacturer specializing in laser cleaning and marking machines.

With a specialized team of R&D and sales engineers, we are at the cutting edge of laser cleaning technological innovation.

Our global reach extends predominantly to Europe and Latin America, serving a diverse clientele that values quality and customization.

We operate under a dual business model, catering to both B2C and B2B clients with one-to-one professional service.

Our commitment to quality assurance is unwavering, ensuring that each laser equipment meets the industry’s highest standards. Choose Chihalo for a reliable, long-term partnership that offers you a distinct competitive edge.

Our gallery

Factory Tour

Welcome to visit our factory! We are delighted to show you our state-of-the-art facilities, cutting-edge technology, and skilled workforce. Explore our production processes, witness our commitment to quality, and experience firsthand the passion that drives our team. Feel free to ask questions and discover why our factory is a leader in the industry.

Customers reviews

What people say

Frequently Asked Questions

A CO2 laser marking machine is a type of laser marking system that utilizes a carbon dioxide laser to etch or engrave materials. It emits a high-energy beam of infrared light that can mark various surfaces, including wood, acrylic, glass, paper, plastics, and certain metals.

A CO2 laser marking machine works by emitting a concentrated beam of infrared light through a series of mirrors and lenses. This beam interacts with the material’s surface, causing it to heat up and vaporize, leaving behind a permanent mark. The process is highly precise and can create detailed designs or alphanumeric characters with exceptional clarity.

CO2 laser marking machines can mark a wide range of materials, including plastics, acrylics, glass, wood, leather, paper, fabrics, ceramics, coated metals, and certain types of rubber. This versatility makes them ideal for various industries such as manufacturing, electronics, packaging, medical devices, and automotive.

When operating a CO2 laser marking machine, it’s essential to follow safety guidelines to prevent accidents and ensure the well-being of operators. This includes wearing appropriate protective gear such as safety glasses to shield against laser radiation, ensuring proper ventilation to remove fumes generated during marking, and implementing safety interlocks to prevent unauthorized access to the laser enclosure.

Yes, CO2 laser marking machines can be seamlessly integrated into automated production lines to facilitate continuous marking of products without manual intervention. Integration may involve incorporating the laser system with robotics, conveyor systems, or other machinery to enable efficient marking of parts as they move through the production process.

CO2 laser marking machines offer several advantages, including high precision, fast marking speeds, versatility in marking various materials, non-contact processing which eliminates the need for physical tooling, and the ability to produce permanent, durable marks that are resistant to wear and fading.

When selecting a CO2 laser marking machine, important factors to consider include laser power, marking speed, marking area size, software capabilities for design and control, cooling system efficiency, maintenance requirements, and the overall build quality of the machine. It’s also essential to evaluate the reputation of the manufacturer and the level of technical support provided.

Yes, CO2 laser marking machines are widely used in industrial production settings due to their efficiency, precision, and versatility. They can handle high-volume marking tasks with consistent quality, making them suitable for applications such as product identification, serial numbering, branding, and traceability in various manufacturing processes.

To optimize the performance of a CO2 laser marking machine, regular maintenance is crucial. This includes cleaning the optics and lenses to ensure optimal beam quality, checking and calibrating the laser system regularly, and monitoring the cooling system to prevent overheating. Additionally, staying updated with software upgrades and implementing best practices for design and setup can help maximize efficiency and quality of marking results.

Maintenance requirements for a CO2 laser marking machine typically include cleaning the optics and lenses regularly to ensure optimal beam quality and performance. Additionally, it’s essential to inspect and replace consumable parts such as laser tubes, mirrors, and lenses as needed to prevent degradation of marking quality. Regular calibration of the laser system and monitoring of cooling system components are also essential to maintain reliability and prolong the lifespan of the machine. Regular maintenance schedules should be established based on usage frequency and manufacturer recommendations to ensure consistent operation and minimize downtime.